Efficient waste gas washing tower

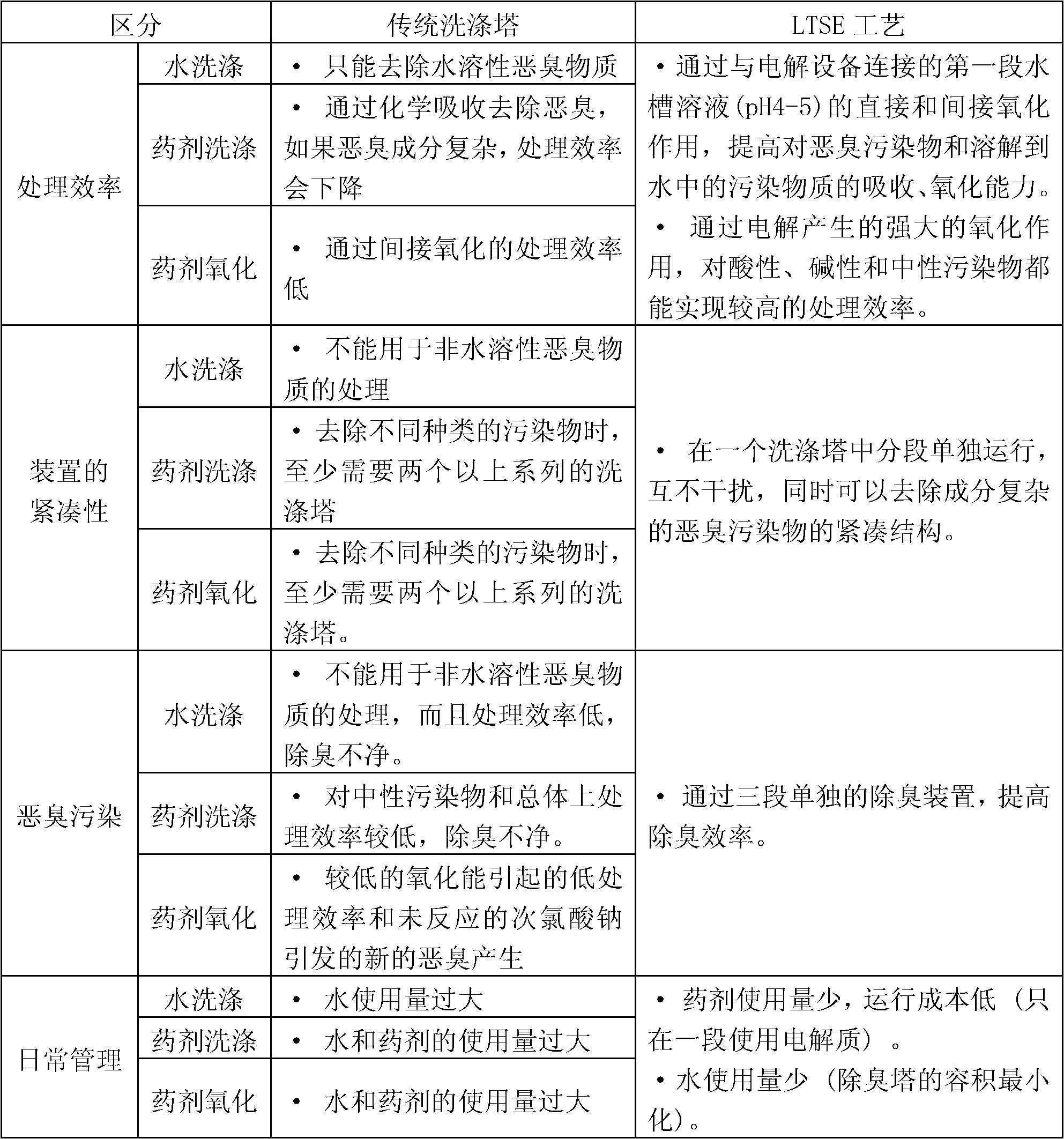

A high-efficiency technology for waste gas washing, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of complex structure of the washing tower, and achieve the effects of low operating costs, reduced pressure, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

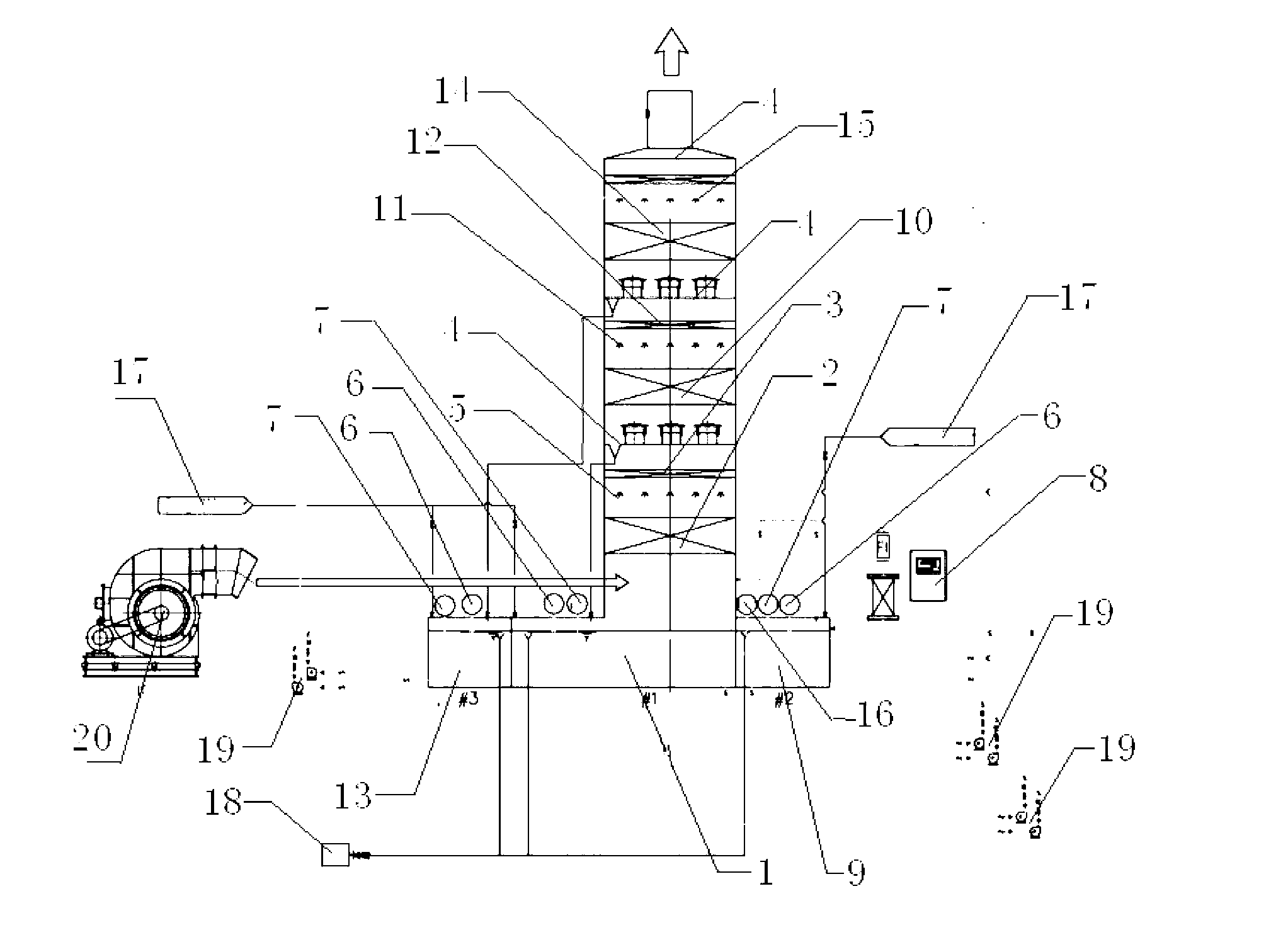

[0026] like figure 1 As shown, a high-efficiency exhaust gas scrubber of the present invention includes three independent deodorizing devices, the first-stage deodorizing device, the second-stage deodorizing device and the third-stage deodorizing device are arranged from bottom to top, and the gas outlet is located at the first Above the third-stage deodorization device, the fan is connected to the first-stage deodorization device through pipes:

[0027] The first stage deodorization device comprises the storage tank 1 of oxidant solution, the dosing device of oxidant solution, the electrolysis device, the contact part 2 of oxidant solution, the removal part 3 of oxidant solution, the layer separation platform 4, the throwing device of described oxidant solution The adding device includes a metering pump 6 and an automatic pH detector 7 to automatically and continuously add the oxidizing agent solution. The electrolysis device includes a rectifier 8 and an electrode plate. Ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com