Method for producing thick-wall hollow valve cores of large-scale ball valves

A production method and hollow valve technology, which is applied in the field of large-scale ball valve parts manufacturing, can solve the problems of complex production process of thick-walled hollow valve core, difficult to reliably guarantee product accuracy, complicated calculation and lofting, etc., to reduce processing costs and ensure accuracy , The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following combined with the attached drawings and the embodiment further explain the present invention:

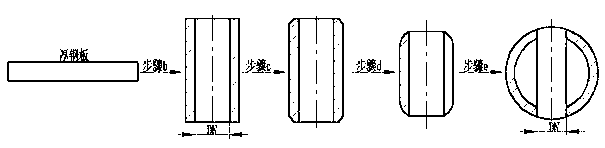

[0023] Reference figure 1 , A thick wall empty valve core production method of a large ball valve, the steps are as follows:

[0024] A, the material is selected, the material is steel plate, the steel plate is preferably stainless steel plate, and the thickness of the steel plate is 50 to 200mm, and the length of the steel plate is determined according to the diameter DN of the steel pipe required by step b.

[0025] B. Roll tube, roll the thick steel plate selected by the step A through a large rolling machine into a round tube, and then welded the gap in the connection. Finally, the thick wall has a seam steel pipe, and the diameter of the steel pipe is DN≥2.6m.

[0026] C. Inverted cone surface, the two tubes of the steel pipe obtained by step B are poured into a cone surface, and the conicalness of the cone surface is preferably 30 ° to 45 °.In addition, step C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The way to | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com