Discharge device and discharge method for vertical shaft type rolling sand storage material

A discharge device and shaft-type technology, which is applied in the field of discharge devices, can solve the problems of easy arching, unsmooth discharge, hardening and unfeeding, etc., to achieve reduced adhesion, increased fluidity, and expanded vibration range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

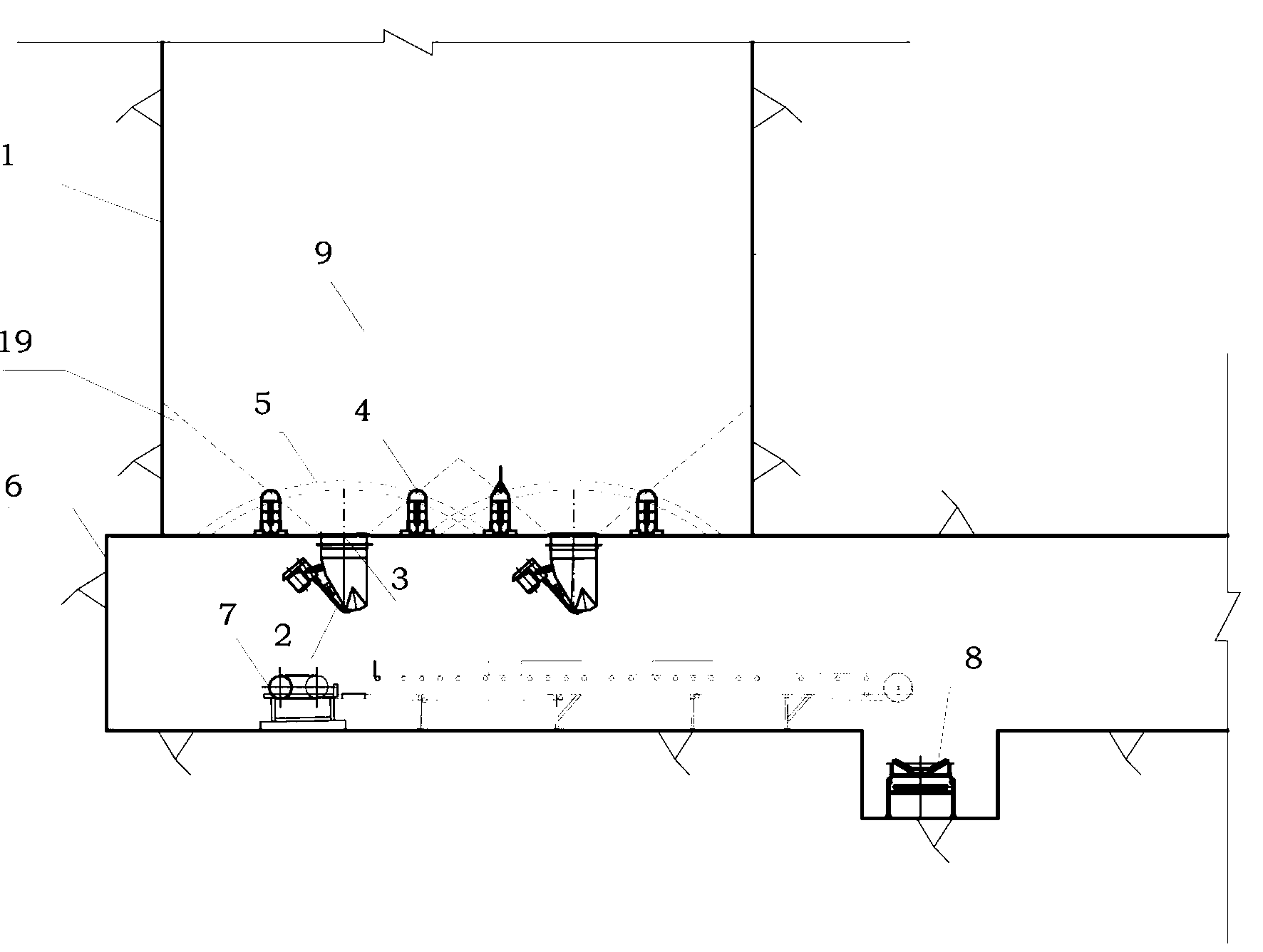

[0016] The structure of the present invention is as figure 1 and figure 2 As shown in the figure, there is a shaft-type discharge device for compacted sand storage. The bottom of shaft 1 is equipped with equipment vibrating feeder 2. The equipment vibrating feeder 2 cooperates with discharge port 3, and the surrounding area of discharge port 3 is evenly arranged. A vibrating bar device 4 is arranged, and the vibrating bar device 4 extends into the arching and hardening area 5, and a tape conveyor 7 is arranged below the vibrating feeder 2 of the equipment.

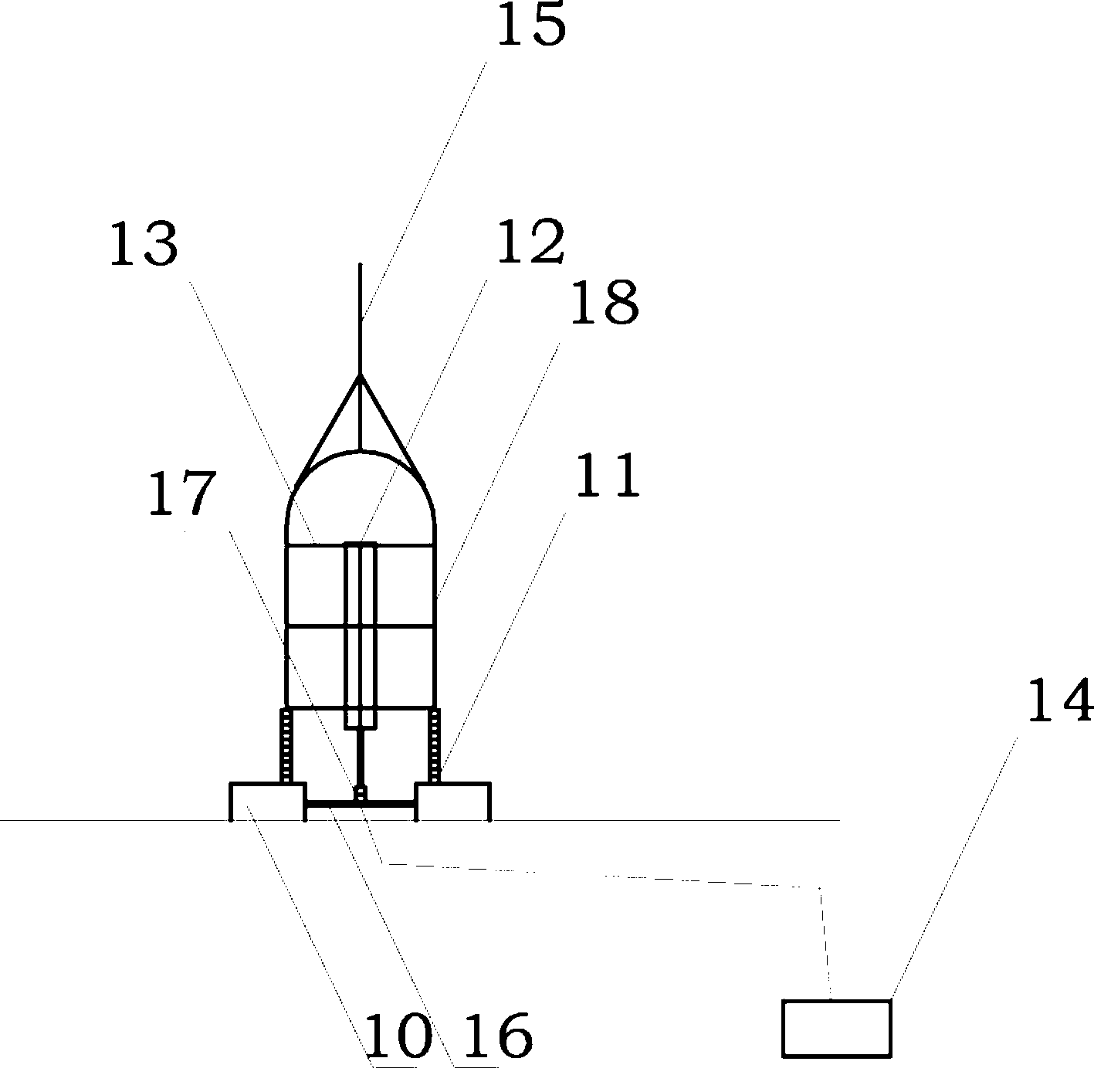

[0017] The vibrating bar device 4 of the present invention includes a fixed shell 18 installed on the base 10, the fixed shell 18 is connected with the hard shaft vibrating bar 12 by the shell connecting plate 13, and a buffer pad is arranged between the fixed shell 18 and the contact surface of the base 10 11. A hard shaft vibrating rod 12 is arranged inside the fixed shell 9, and the hard shaft vibrating rod 12 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com