Epoxy modified polysiloxane low surface energy antifouling coating and preparation method thereof

A low surface energy, epoxy-modified technology, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problem of easy peeling, difficult repainting, and changes in the surface state of antifouling coatings and other problems to achieve the effect of increasing adhesion and ensuring adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

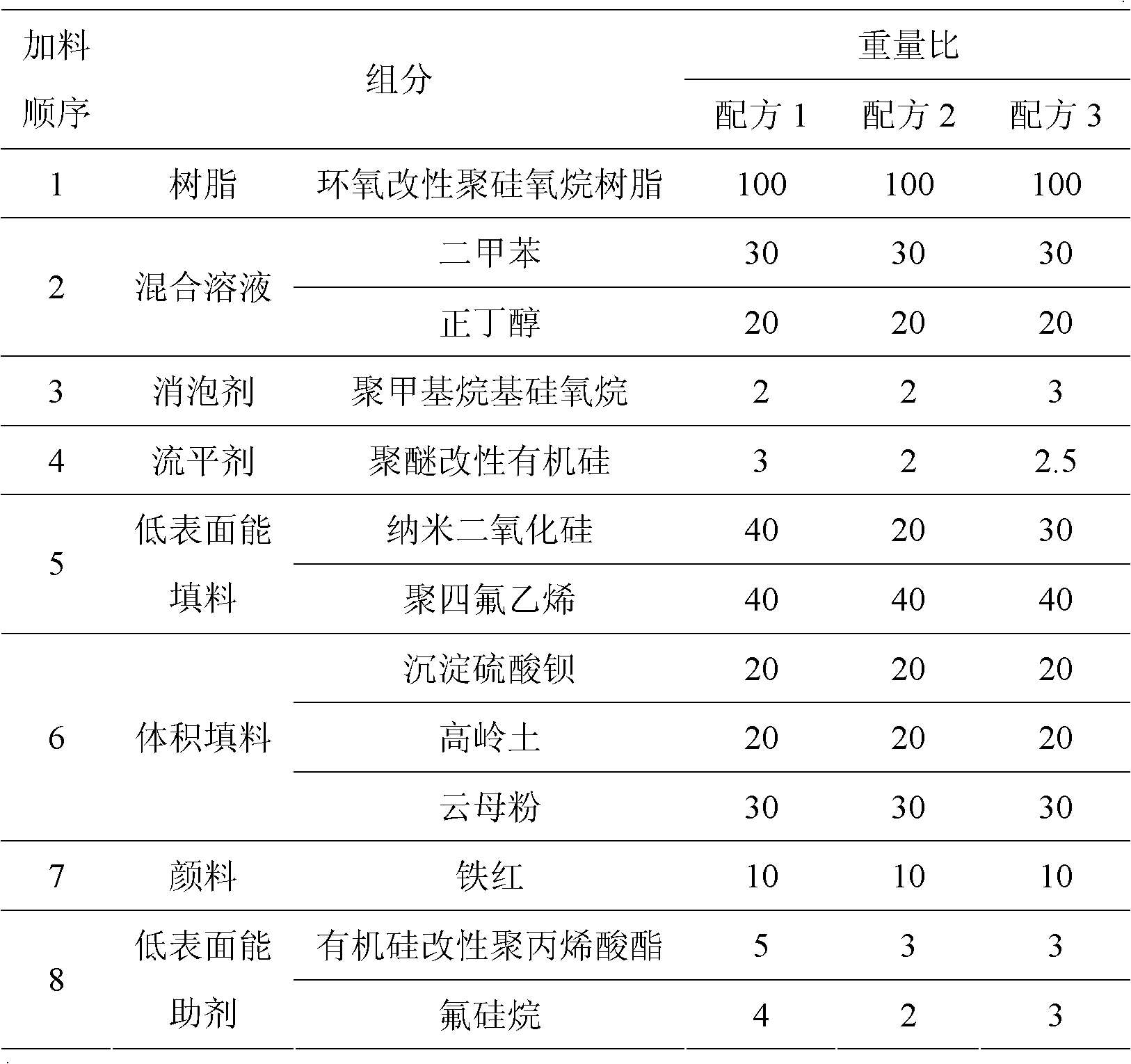

[0022] Specific examples of the epoxy-modified polysiloxane antifouling coating formulation of the present invention are shown in the following table.

[0023]

[0024] Preparation of epoxy-modified polysiloxane antifouling paint: In a stainless steel bucket, add various components in sequence according to the paint preparation method, stir at high speed for 0.25h, grind with a sand mill for 0.5h, and discharge to the stainless steel tank. In the material barrel, add low surface energy additives, stir at a high speed for 0.2h, and discharge the material to obtain component A in the coating; when used, 100 parts by weight of component A and 15 parts by weight of component B are mixed uniformly to make Epoxy modified polysiloxane low surface energy coating.

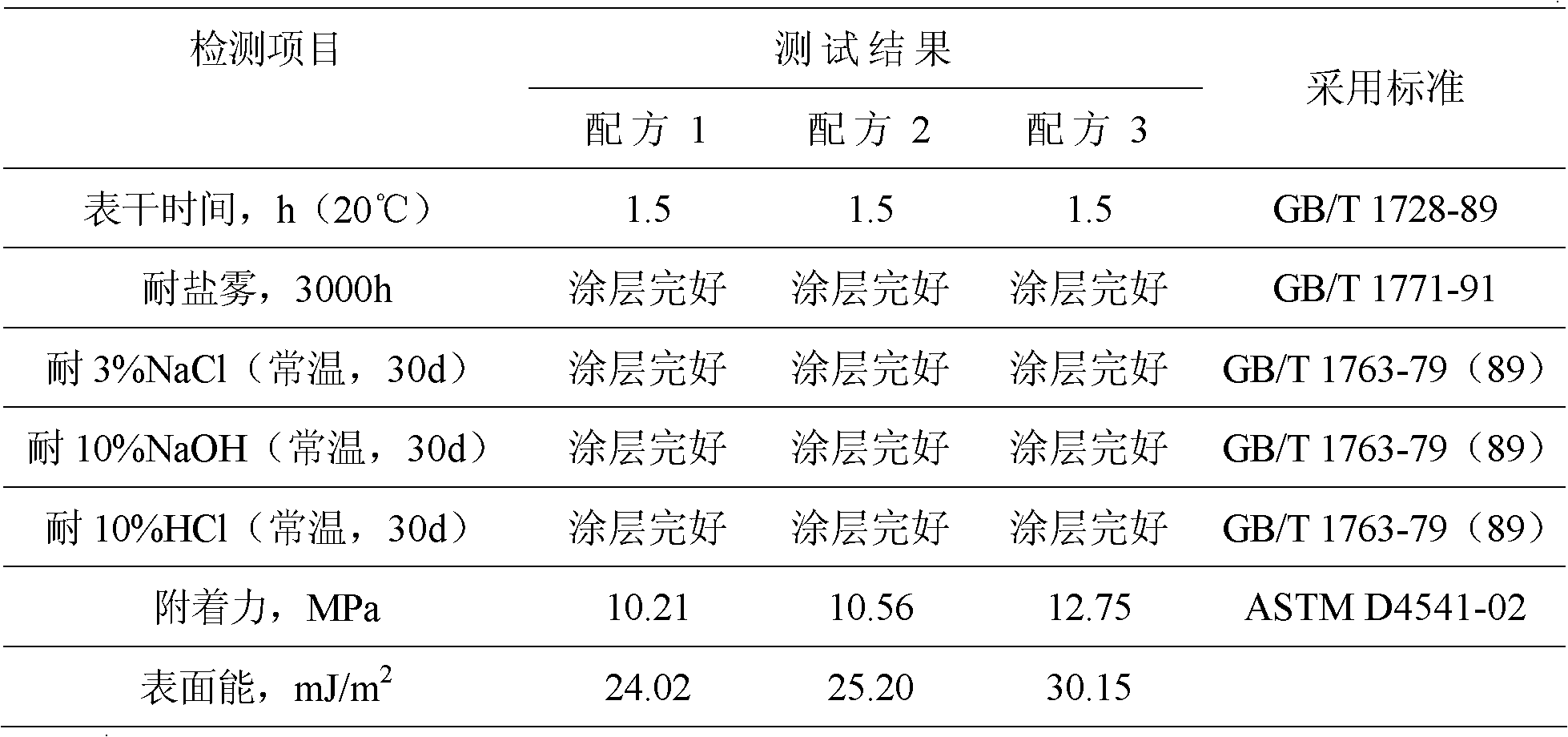

[0025] The epoxy-modified polysiloxane coating achieves the following properties:

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com