Switching device and switching method for fiber optic micro cable of underwater robot

An underwater robot and transfer device technology, which is applied in the directions of underwater operation equipment, transportation and packaging, fiber mechanical structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

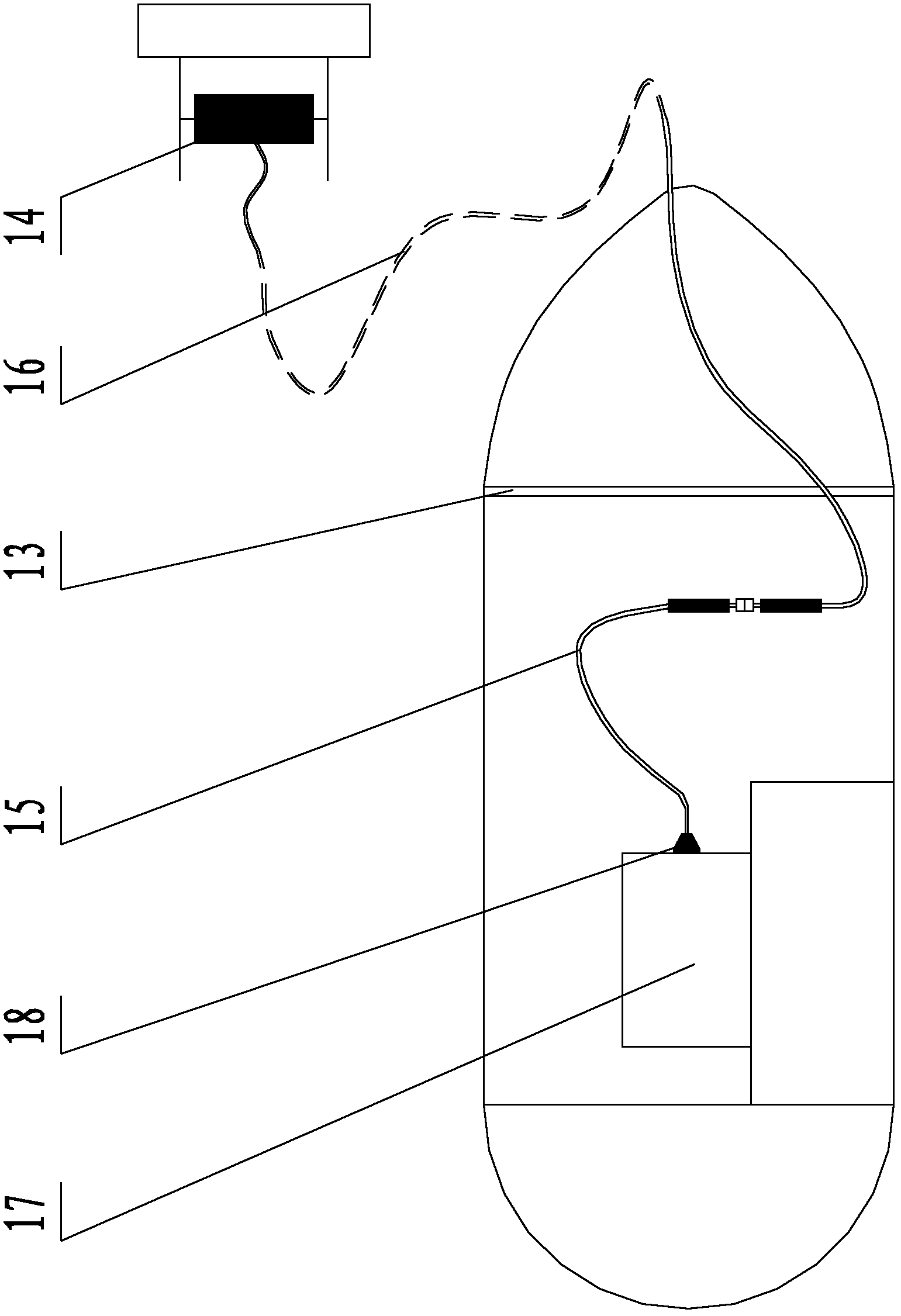

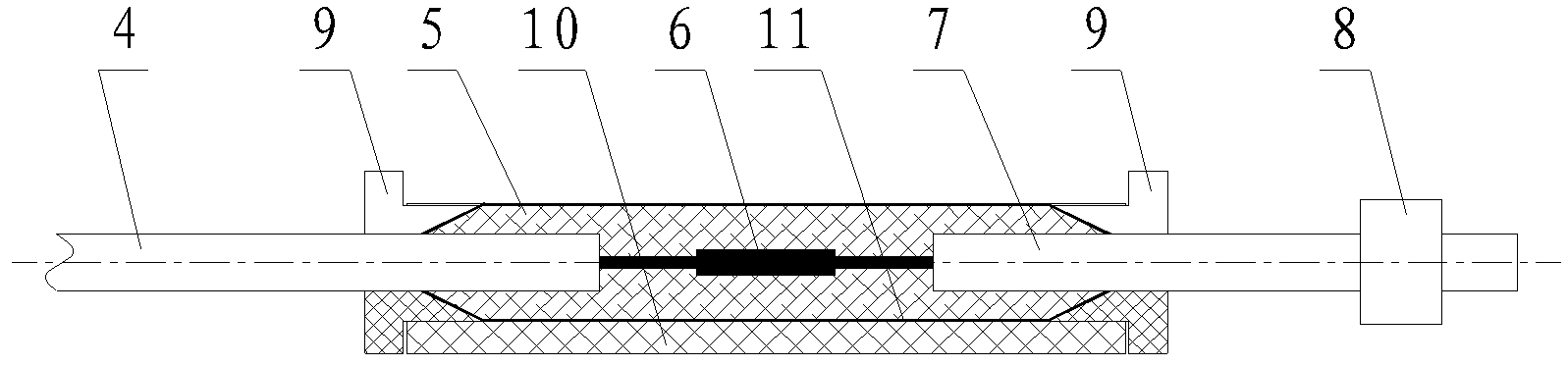

[0028] like figure 1 As shown, within the scope protected by the underwater robot carrier frame 13, the first optical fiber microcable 15 drawn out by the underwater robot sealed cabin 17 and the first optical fiber microcable 15 introduced by the optical fiber retracting device 14 are sealed with the aid of the sealing mold by using a sealant. The two optical fiber microcables 16 are respectively sealed, and then the transfer between the first optical fiber microcable 15 and the second optical fiber microcable 16 is realized through the optical fiber transfer terminal 8, that is, one end of the first optical fiber microcable 15 is sealed with the sealing cabin 17, A sealing place 18 is formed, and the other end is transferred to one end of the second optical fiber microcable 16 through the optical fiber transfer terminal 8 , and the other end of the second o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com