Device for generating vector light beam through annular combination half wave plate

A ring beam and half-wave plate technology, used in optics, optical components, instruments, etc., can solve the problems of unable to generate vector beams, increase the loss in the central area, reduce optical purity, etc., achieve a high laser damage threshold, and improve reflectivity. , the effect of high beam purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

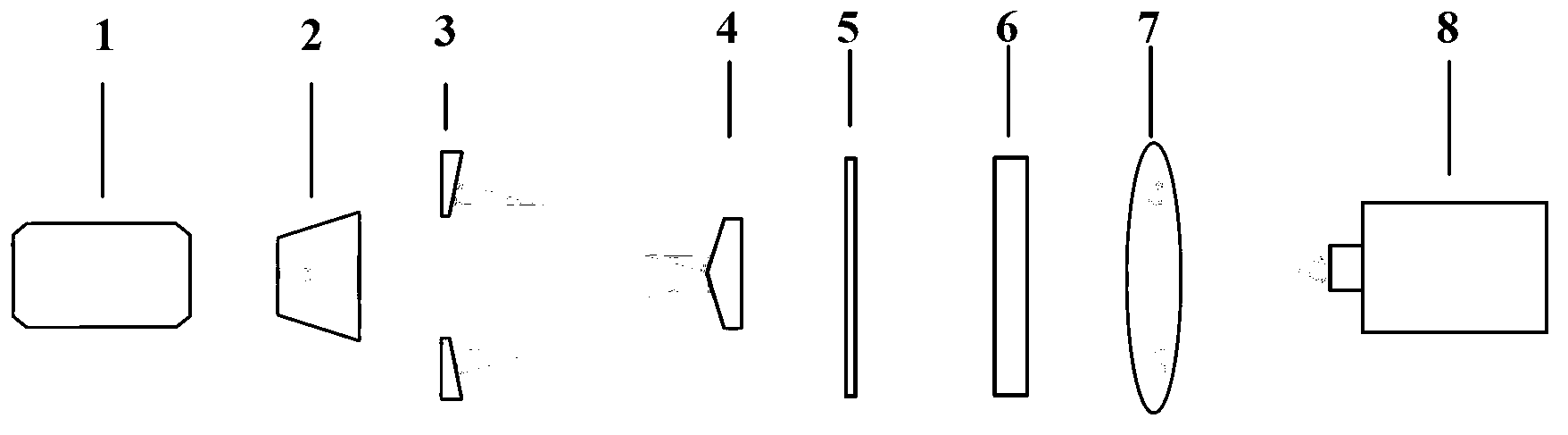

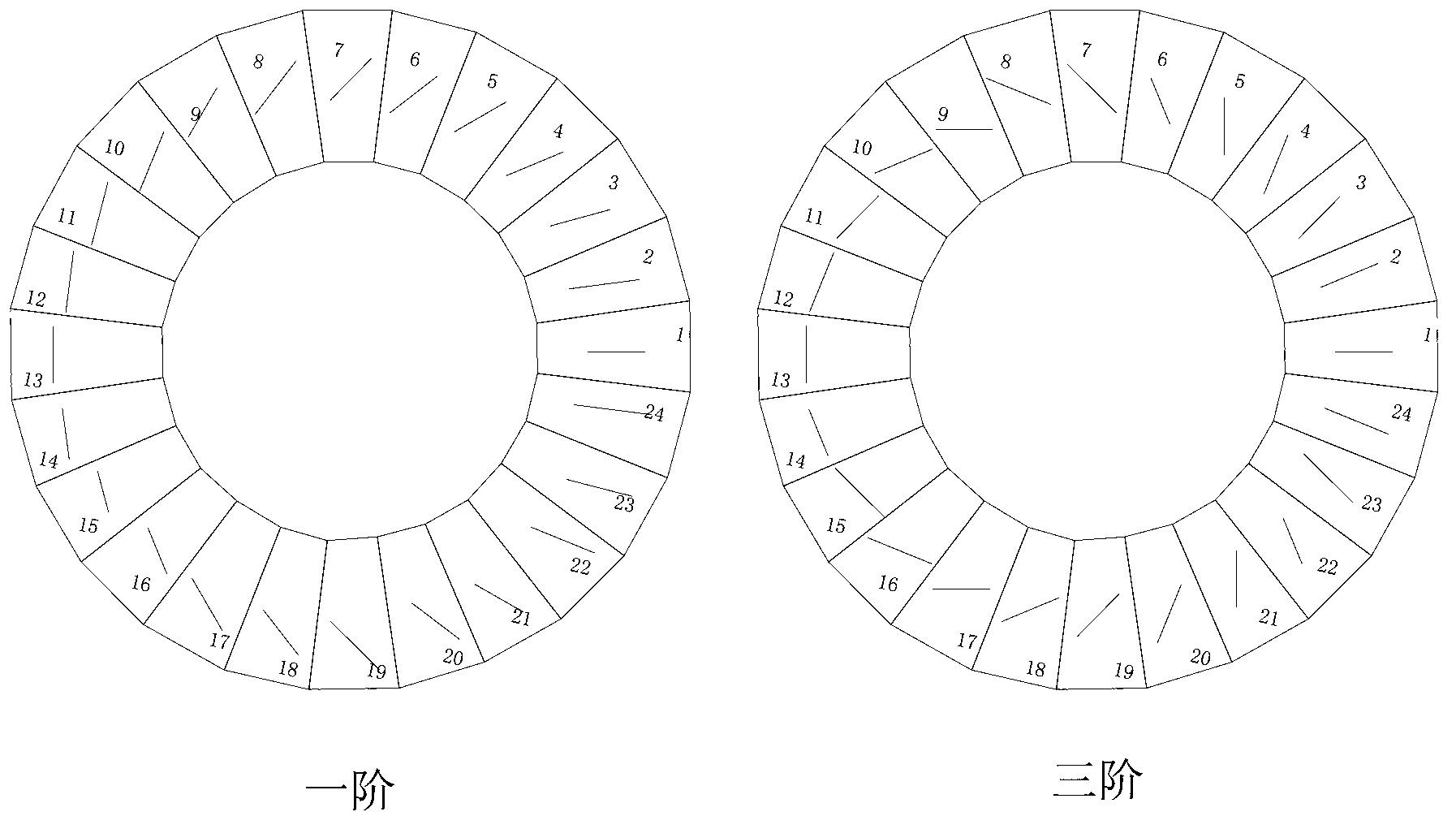

[0024] The present invention provides a kind of device that produces vector beam with annular combination half-wave plate, comprises laser 1, beam expander, annular beam converter, annular combination half-wave plate 6, polarizer 5 and focusing lens 7, for receiving generation The vector beam of light is placed on the focal plane of the focusing lens 7 with a CCD camera 8 .

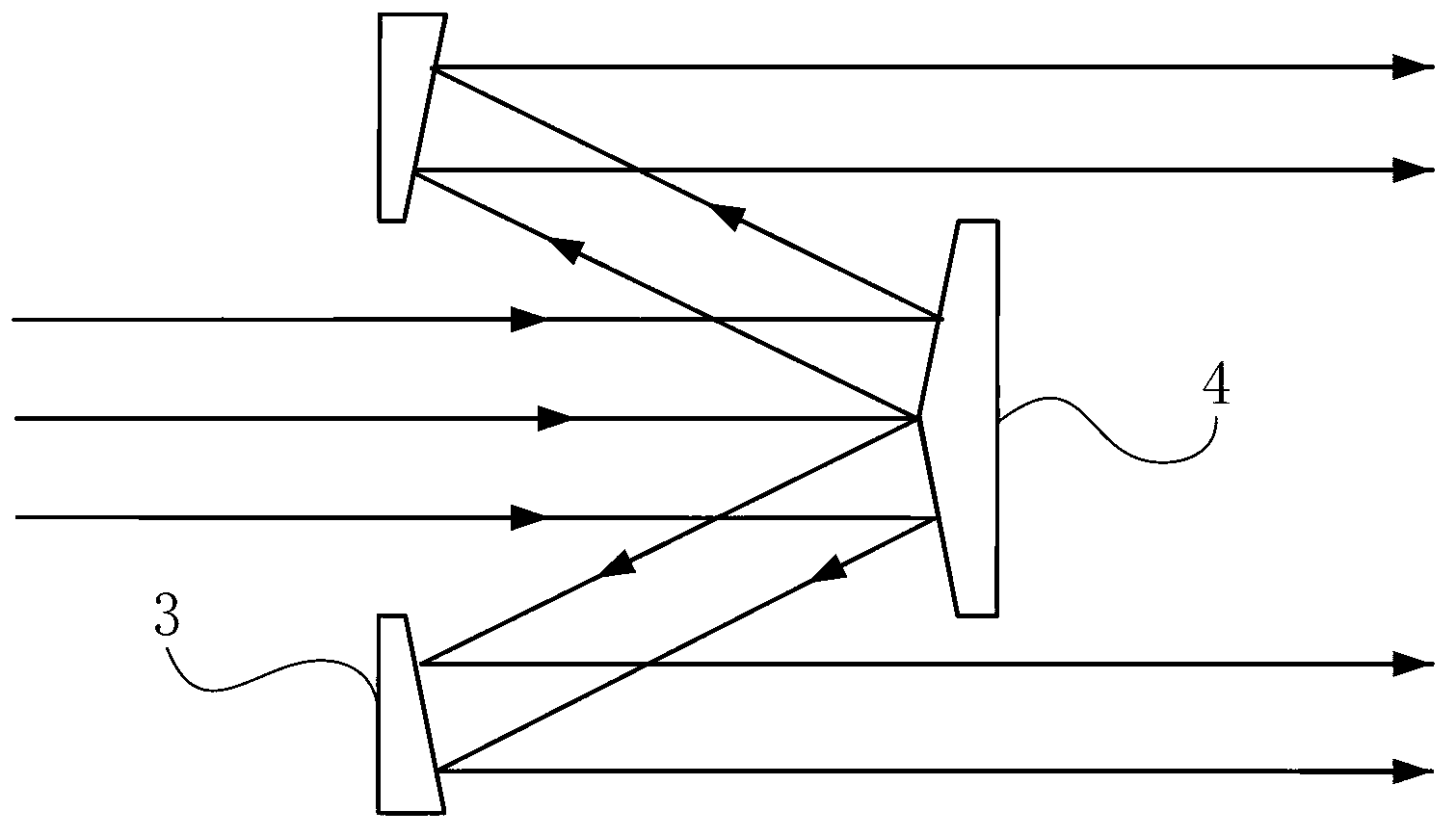

[0025] A Gaussian beam emitted from the laser 1 is collimated and expanded by the beam expander 2, and then vertically incident on the ring beam converter, and the generated ring beam passes through a polarizer 5 placed at 0° and then vertically incident on the ring combination After the half-wave plate, a light field with an axisymmetric distribution of the polarization state is formed, and after the transformation of the light field by the focusing lens 7, a high-purity vector beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com