Monitoring method after removal of polysilicon dummy gate

A polysilicon and dummy gate technology, which is used in semiconductor/solid-state device testing/measurement, semiconductor devices, electrical components, etc., can solve problems such as slow feedback results, wafer destructiveness, and complexity, and achieve intuitive feedback results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

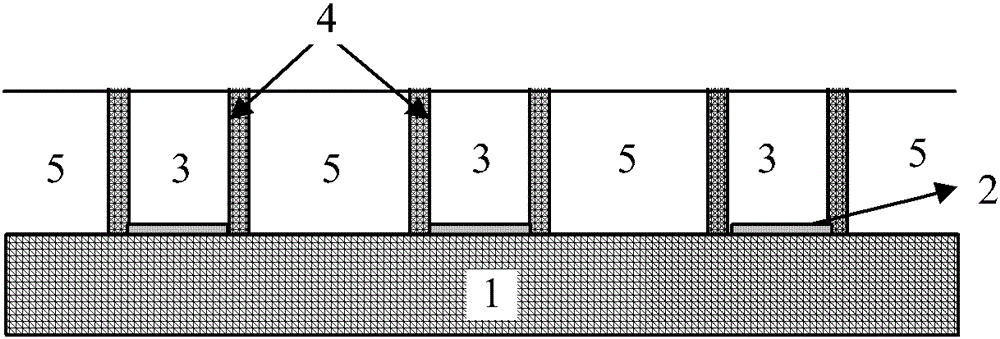

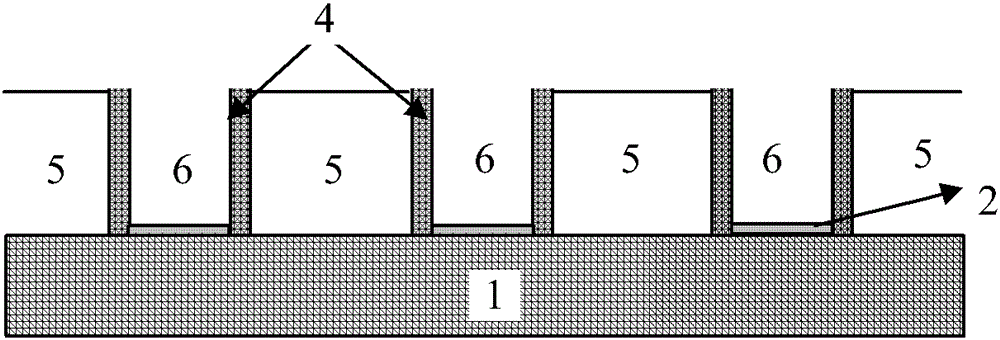

[0021] Referring to accompanying drawing 1, insulator layer 2, polysilicon dummy gate 3, gate side wall 4, interlayer dielectric layer (ILD) 5 are sequentially formed on substrate 1, then polysilicon dummy gate 3 is removed, and gate opening 6 is formed . It can be seen from FIG. 1 that after the removal of the polycrystalline dummy gate 3, the quality of the thin film of the wafer (that is, the ILD5 on the wafer surface and the sidewalls 4 sandwiched therebetween, and the thin films of the gate opening 6 The sum of mass) will be significantly reduced, so by monitoring the quality of the wafer, it can be judged whether the polycrystalline dummy gate is completely removed; the measurement by this method will have the advantages of intuitive test results, no damage to the wafer and high measurement efficiency It is suitable for the effective monitoring of the process after the polysilicon dummy gate is removed.

[0022] Specifically, a monitoring method for removing a polysilic...

Embodiment 2

[0029] Similar to Embodiment 1, a monitoring method for removing a polysilicon dummy gate in a gate-last process according to another embodiment of the present invention includes the following steps:

[0030] First, a polysilicon dummy gate structure is formed on the surface of the wafer. As shown in FIG. 1, a polysilicon dummy gate structure is formed on the surface of the wafer, that is, an insulating layer 2, a polysilicon dummy gate 3, a gate sidewall 4, and an interlayer dielectric layer (ILD) 5 are sequentially formed on a substrate 1. Then the polysilicon dummy gate 3 is removed to form a gate opening 6 .

[0031]Second, determine the measurement target and error range. The polysilicon dummy gate can be formed on the test wafer (that is, the spare wafer that is not used for final cutting into chip products) according to the process, and through this experimental design (designofexperimental, DOE) and the use of quality testing methods, it can be determined that a certa...

Embodiment 3

[0036] Similar to Embodiment 1 or 2, the only difference lies in whether the insulating layer 2 is a gate dielectric layer of the gate-last process. If the insulating layer 2 is a high-k material for the gate dielectric layer of the gate-last process, then in the monitoring method of the present invention, the insulating layer 2 is not removed along with the polysilicon dummy gate 3, but is retained together, so the monitoring method does not Change. But if the insulating layer 2 is only used for the etch stop layer of the polysilicon dummy gate 3, that is, the material is a common insulating dielectric material, such as silicon dioxide, then the insulating layer 2 should be removed together with the polysilicon dummy gate 3, then the present invention Corresponding changes need to be made in the above two embodiments.

[0037] Specifically, the monitoring method for the variation of embodiment 1 in embodiment 3 includes:

[0038] 1) Use the quality measurement monitoring me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com