A battery sealing assembly and manufacturing method thereof, and a lithium-ion battery

A technology for sealing components and manufacturing methods, applied in battery pack parts, sealing materials, electrical components, etc., can solve problems such as poor corrosion resistance and poor sealing performance, and achieve good sealing effect, improved service life, and reliable connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

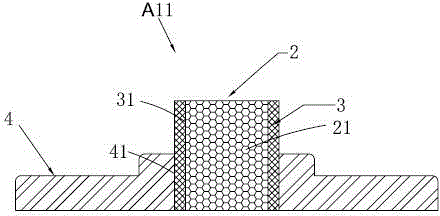

[0046] This embodiment combines figure 1 For illustrating the making of the sealing assembly of the negative electrode of the battery of the present invention:

[0047] figure 1 The manufacturing method of the sealing assembly of the positive electrode of the battery shown in Example 1 comprises the following steps:

[0048] Step 1, forming the ceramic ring: the ceramic powder of 95wt% alumina (also containing 5wt% glass sintering phase, as the composition is CaO-MgO-Al 2 o 3 -B 2 o 3 The glass) is pressed into a ceramic ring by dry pressing, and a receiving hole is formed in the middle of the ceramic ring;

[0049] Step 2. Form ceramic porous body: Mix alumina ceramic powders with two particle sizes of 12 μm and 2 μm in a weight ratio of 3:1, and then add paraffin to prepare a slurry, wherein the percentage of alumina ceramic powder is 65wt %, fill the slurry into the holding hole of the ceramic ring, then put the ceramic ring and the ceramic material filled in the cerami...

Embodiment 2

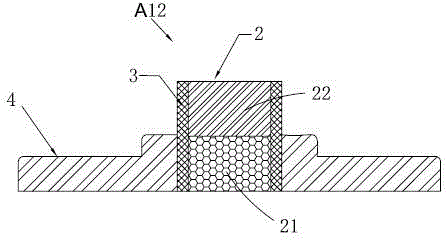

[0053] This embodiment 2 combines figure 2 For illustrating the making of the sealing assembly of the positive electrode of the battery of the present invention:

[0054] figure 1 The manufacturing method of the sealing assembly of the positive electrode of the battery shown in Example 1 comprises the following steps:

[0055] Step 1, forming a ceramic ring: pressing 95wt% alumina ceramic powder into a ceramic ring by dry pressing, and a receiving hole is formed in the middle of the ceramic ring;

[0056] Step 2. Form ceramic porous body: Mix alumina ceramic powders with particle sizes of 12 μm and 3 μm at a weight ratio of 3:1, and then add paraffin to prepare a slurry, wherein the percentage of alumina ceramic powder is 65wt %, fill the slurry into the holding hole of the ceramic ring, then put the ceramic ring and the ceramic material filled in the ceramic ring into the sintering furnace for sintering, and heat up to 600°C at a speed of 0.5°C / min for debinding for 2h , ...

Embodiment 3

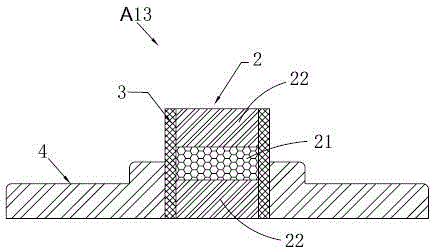

[0060] This embodiment 3 combines image 3 For illustrating the making of the sealing assembly of the positive electrode of the battery of the present invention:

[0061] figure 1 The manufacturing method of the sealing assembly of the positive electrode of the battery shown in Example 1 comprises the following steps:

[0062] Step 1, forming a ceramic ring: pressing 95wt% alumina ceramic powder into a ceramic ring by dry pressing, and a receiving hole is formed in the middle of the ceramic ring;

[0063] Step 2. Form ceramic porous body: Mix alumina ceramic powders with particle sizes of 11 μm and 5 μm in a weight ratio of 3:1, and then add paraffin to prepare a slurry, wherein the percentage of alumina ceramic powder is 65wt %, fill the slurry into the holding hole of the ceramic ring, then put the ceramic ring and the ceramic material filled in the ceramic ring into the sintering furnace for sintering, and heat up to 600°C at a speed of 0.5°C / min for debinding for 2h , a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com