Ultrasonic peening method and floating building

A construction method, ultrasonic technology, applied in shipbuilding, manufacturing tools, metal processing, etc., can solve the problems of reducing the compressive stress field, reducing the improvement effect of ultrasonic shot peening fatigue strength, etc., to achieve the reduction of suppression effect, high efficiency ultrasonic shot peening The effect of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

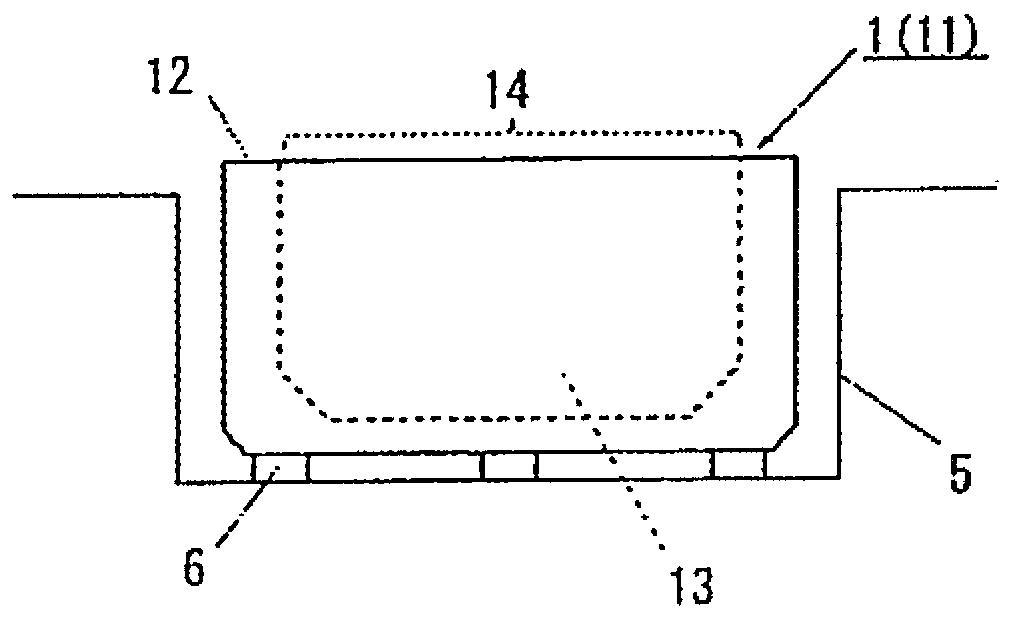

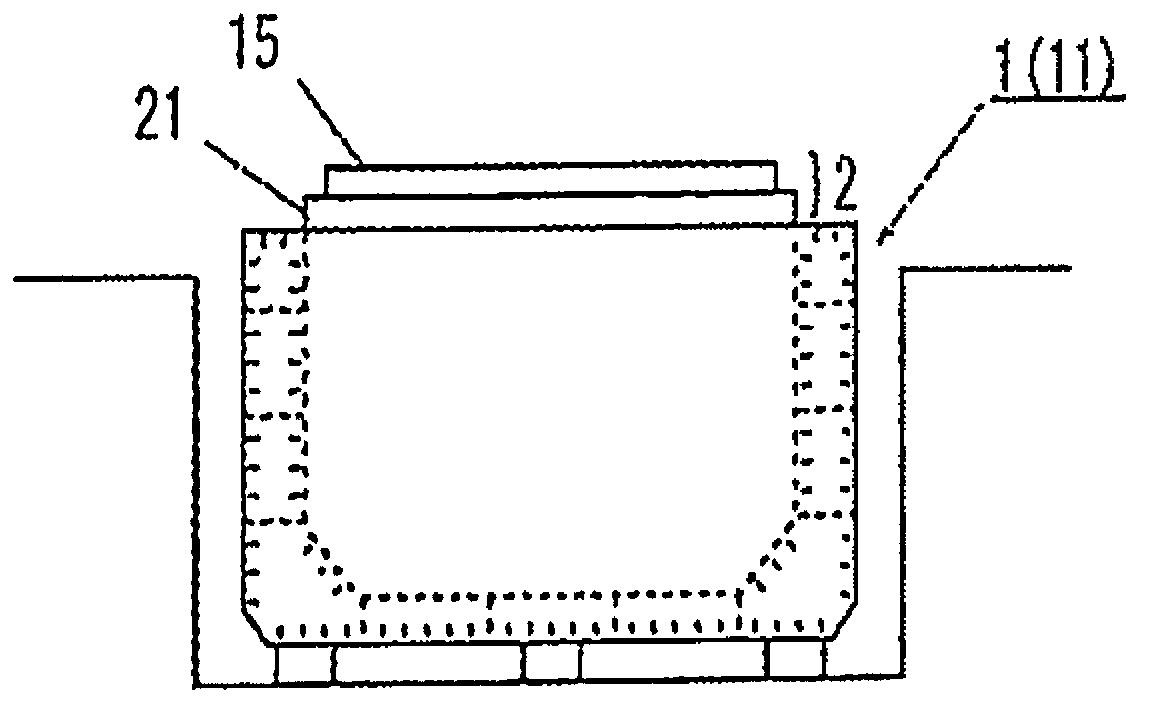

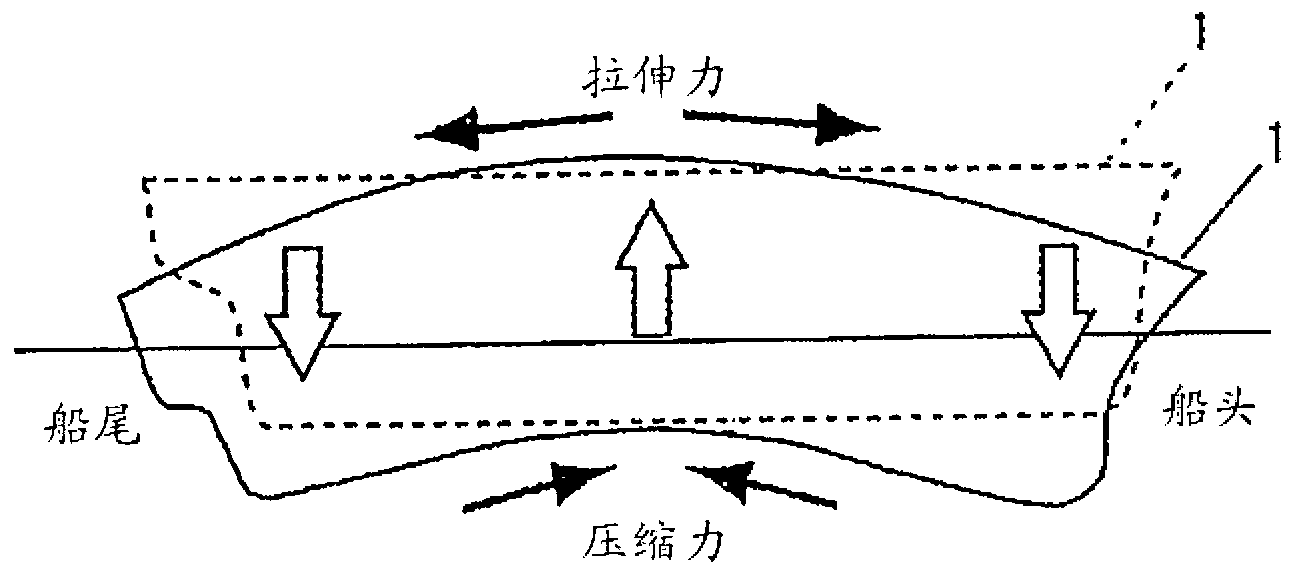

[0067] Next, an embodiment of the present invention will be described using FIGS. 1 to 4 . Here, Fig. 1 shows the ultrasonic shot blasting construction method of the embodiment of the present invention, Figure 1A is the building construction process, Figure 1B It is a structure welding process, Figure 1C It is the building launching process, Figure 1D It is the ultrasonic shot peening process. FIG. 2 is a diagram showing a floating structure according to an embodiment of the present invention, Figure 2A Represents a side view of a container ship, Figure 2B The above diagram representing a container ship. image 3 It is an enlarged perspective view of part III in FIG. 2 . Fig. 4 is a schematic diagram for explaining the ultrasonic shot peening process, Figure 4A A perspective view showing a welded part before ultrasonic shot peening, Figure 4B A perspective view showing a welded portion during ultrasonic shot peening, Figure 4C A perspective view showing a weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com