Method for decolorizing, debitterizing and deodorizing fishskin protein liquid

A fish skin protein and debittering technology, which is applied in the field of fish skin protein solution, can solve the problem of high cost, and achieve the effect of mild and safe treatment process, convenient operation, and low nitrogen loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

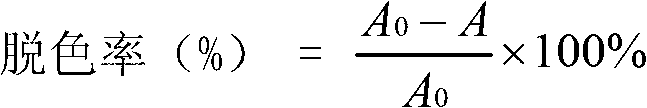

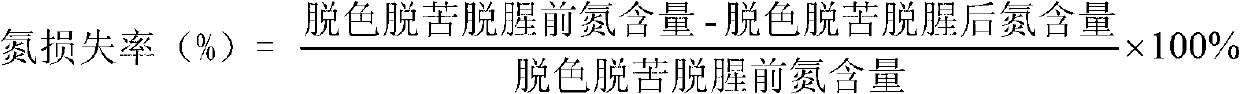

[0016] In the process of preparing the seasoning with pangasius skin, the pangasius skin is pickled to obtain a fish skin protein solution with a protein concentration of 5%. The protein solution is yellow, and the comprehensive sensory value of bitterness and fishy smell is 35. After removing the residue by filtration, heat to 45°C, adjust the pH value to 6.5, add activated carbon with 0.1% weight of fish skin protein liquid while stirring, and act at 45°C for 1 hour to decolorize, debitter, and deodorize; then, the protein The liquid is filtered through a diatomaceous earth filter at 40°C and 3MPa to remove activated carbon, and the product is obtained. The color of the filtrate is light yellow, the decolorization rate reaches 88%, the comprehensive sensory value of the debittering and deodorizing effect reaches 95, the bitterness and fishy smell are extremely weak, and the nitrogen loss rate is 4%.

Embodiment 2

[0018] In the process of preparing protein powder from cod skin, after the cod skin is descaled, a fish skin protein solution with a protein concentration of 10% is obtained by enzymatic hydrolysis. The protein solution is yellow, and the comprehensive sensory value of bitterness and fishy smell is 40. After liquid filtration to remove residue, heat to 50°C, adjust the pH value to 8.0, add activated carbon with 0.5% weight of fish skin protein liquid while stirring, and act at 50°C for 2.5h to decolorize, debitter, and fishy; then, Filter the protein solution through a diatomaceous earth filter at 50°C and 2MPa to remove the activated carbon. The color of the filtrate is light yellow, the decolorization rate reaches 85%, the comprehensive sensory value of the debittering and deodorizing effect reaches 95, the bitterness and fishy smell are extremely weak, and the nitrogen loss rate is 4.8%.

Embodiment 3

[0020] In the process of preparing active peptides from tilapia skin, after the tilapia skin was descaled, a fish skin protein solution with a protein concentration of 1% was obtained by liming. The protein solution was yellow, and the comprehensive sensory value of bitterness and fishy smell was 40. After filtering the fish skin protein liquid to remove the residue, heat it to 65°C, adjust the pH value to 5, add activated carbon with 1% weight of the fish skin protein liquid while stirring, and act at 65°C for 2 hours to decolorize, debitter, and deodorize ; Then, filter the protein solution through a diatomaceous earth filter at 60 ° C and 1.5 MPa to remove activated carbon, that is, the product. The color of the filtrate is light yellow, the decolorization rate reaches 90%, the comprehensive sensory value of the debittering and deodorizing effect reaches 90, the bitterness and fishy smell are extremely weak, and the nitrogen loss rate is 6%.

[0021] The above-mentioned dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com