Method for producing inclined vertical rib structure rotor support frame center body of large-scale vertical generator

A technology for rotor brackets and generators, which is applied in the field of producing the center body of a rotor bracket of a large vertical generator with an oblique vertical rib structure, can solve the problems of adverse effects of the use of the center body, uneven deformation of the center body, large production cycle, etc. Uniform, consistent welding speed, consistent heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

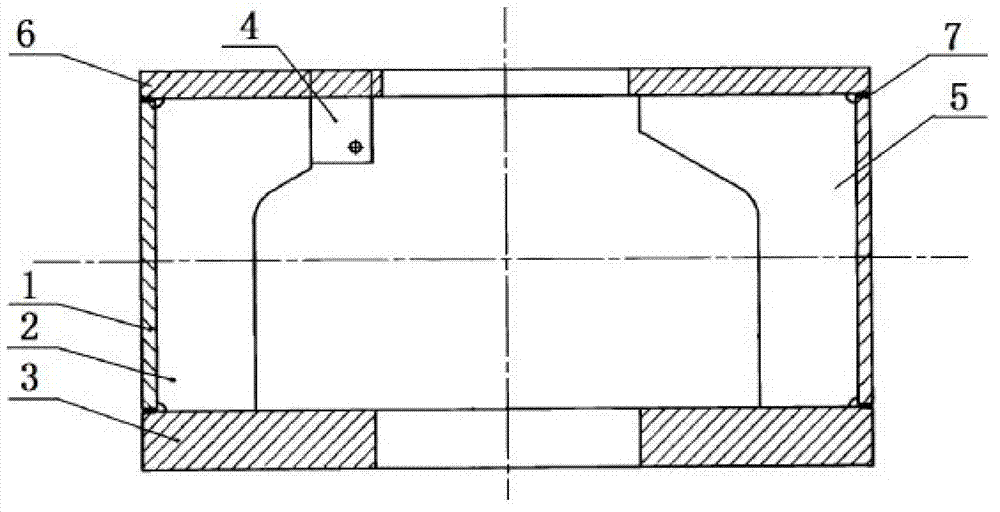

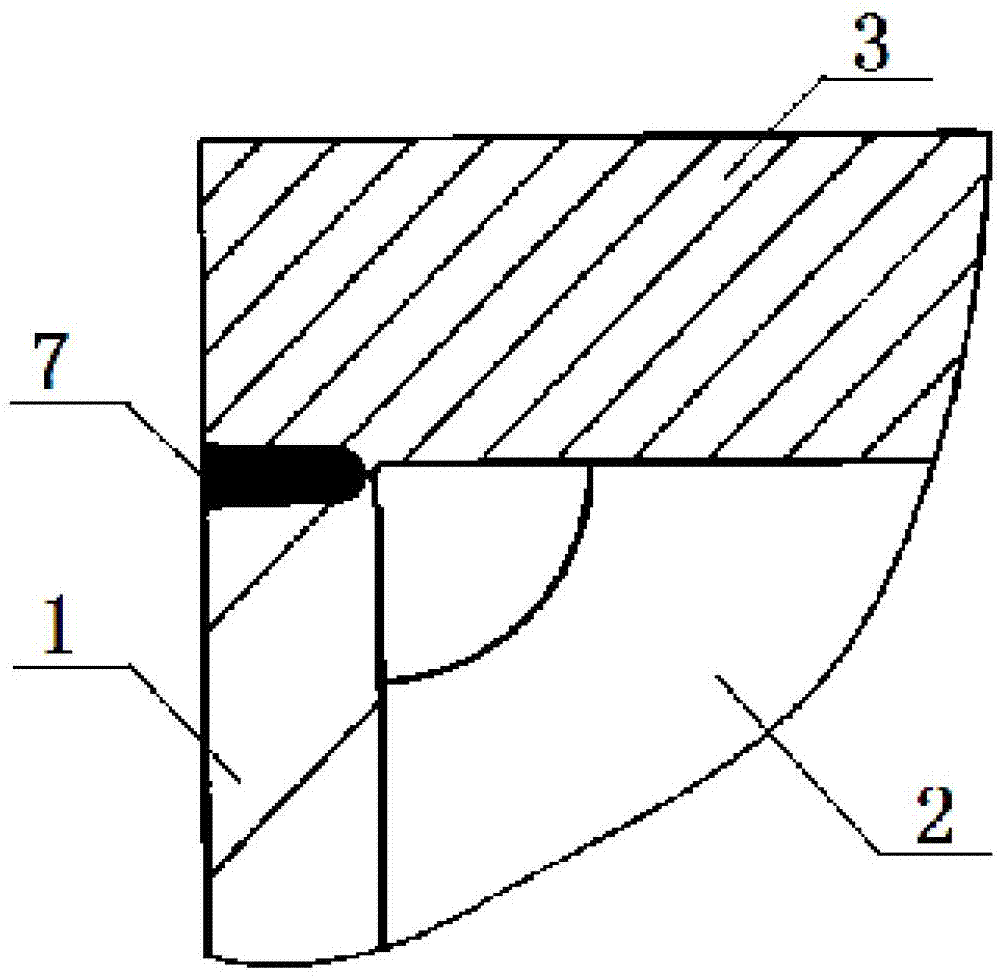

[0011] The invention relates to a process method for producing the center body of a rotor bracket with oblique rib structure for a large-scale vertical generator. The technical solution of the invention is: (1) Prepare materials for the center cylinder and the upper and lower ring plates: use a numerical control gas cutting machine to cut the material, and the center cylinder The molding allowance is reserved, the upper and lower ring plates are blanked according to the theoretical size, the center tube is not flattened after blanking, and the upper and lower ring plates are flattened after blanking; (2) Center tube forming: heat the center tube to 1050°C, and the holding time is according to T =αD(T——Heating time (min); α——1~1.2 (min / mm); D——The effective thickness of the workpiece (mm)) Calculation, using a 60mm plate rolling machine to heat roll the center cylinder; (3 ) Removal of center tube allowance: After the center tube is basically formed, mark the line, remove the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com