Liquid crystal glass panel packaging structure

A technology of liquid crystal glass and packaging structure, applied in the field of packaging, can solve the problems of liquid crystal glass panel breakage, difficult to fix, difficult to fix, etc., and achieves the effects of reducing transportation cost, low price, and good buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

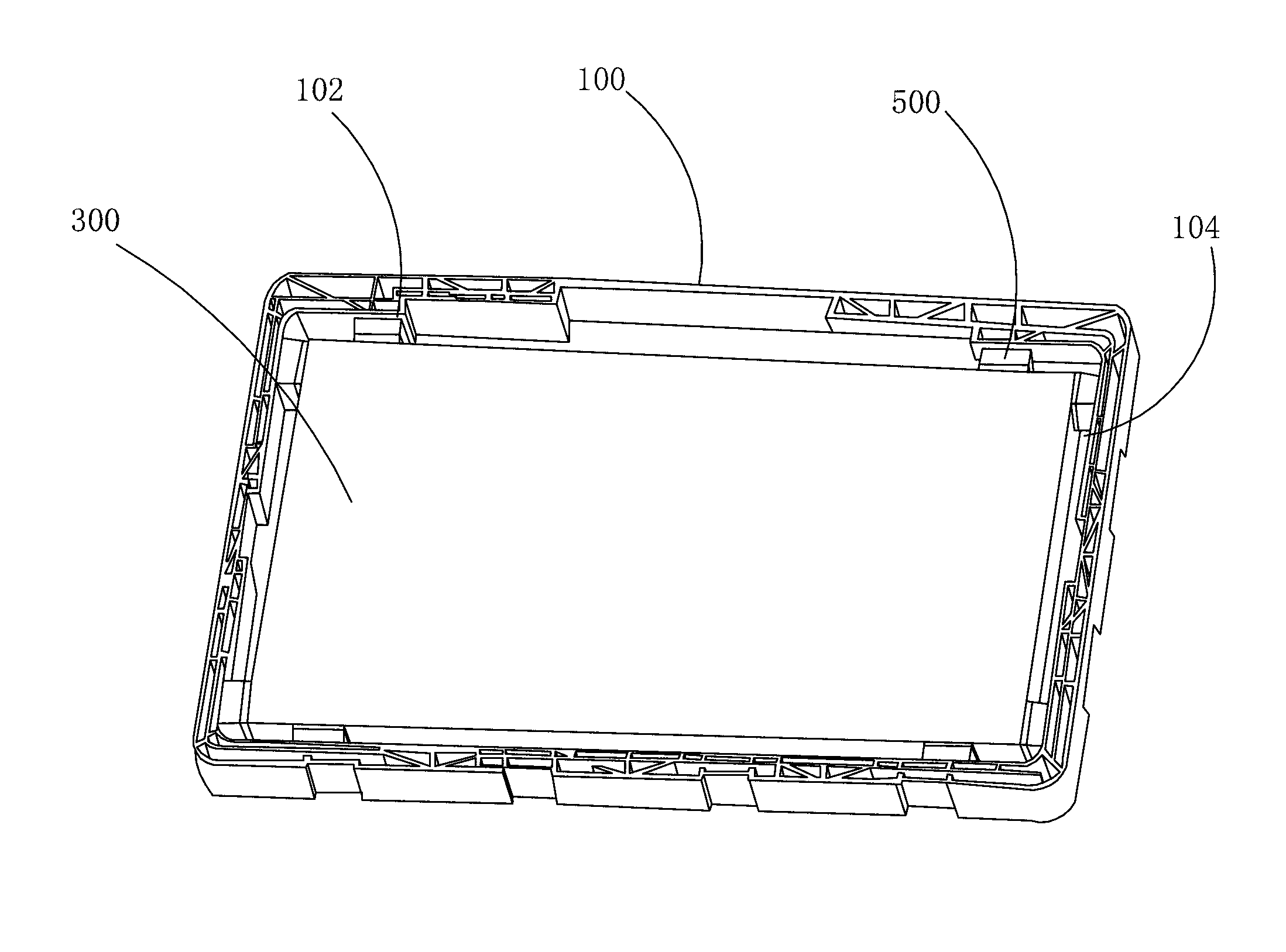

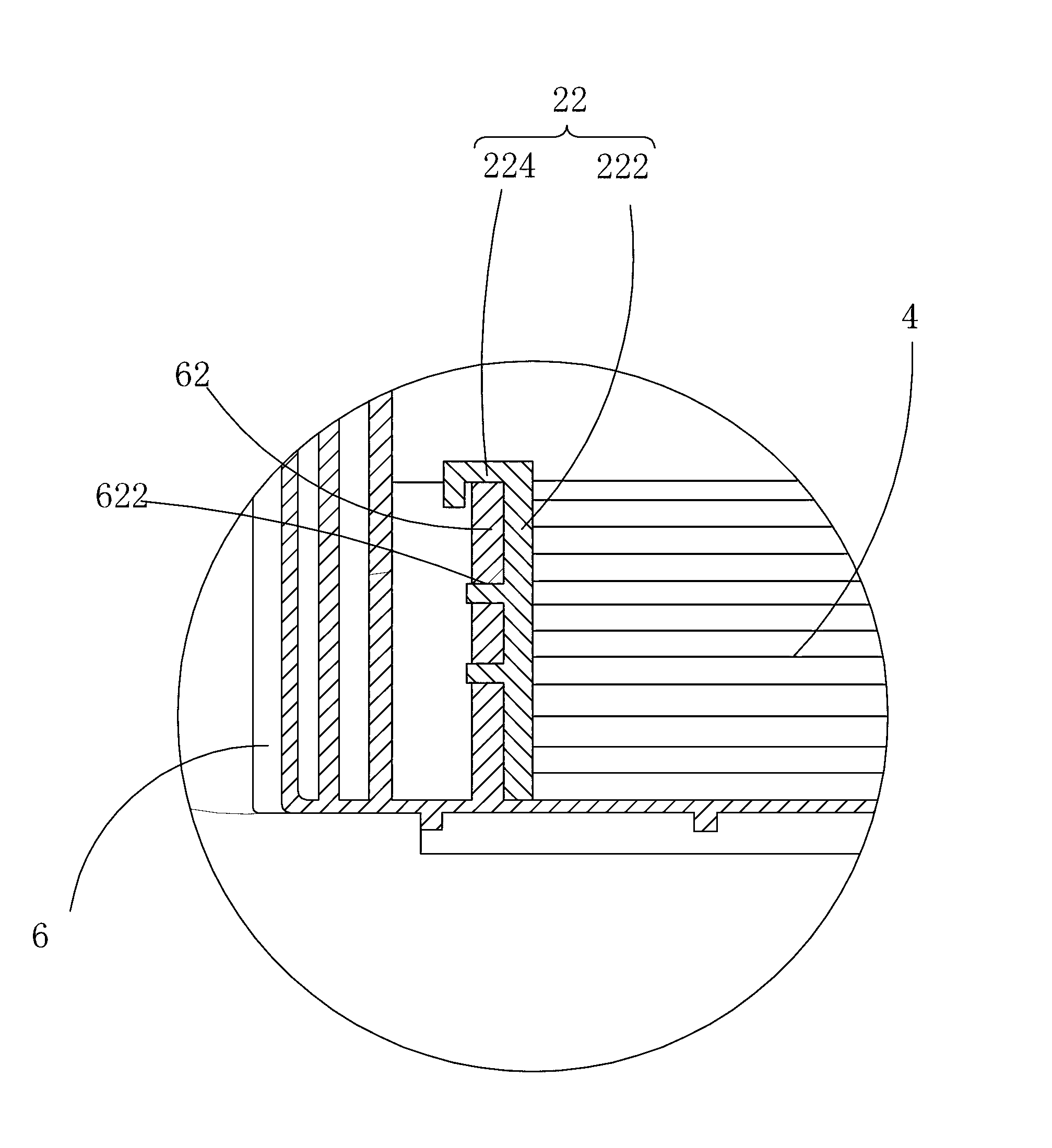

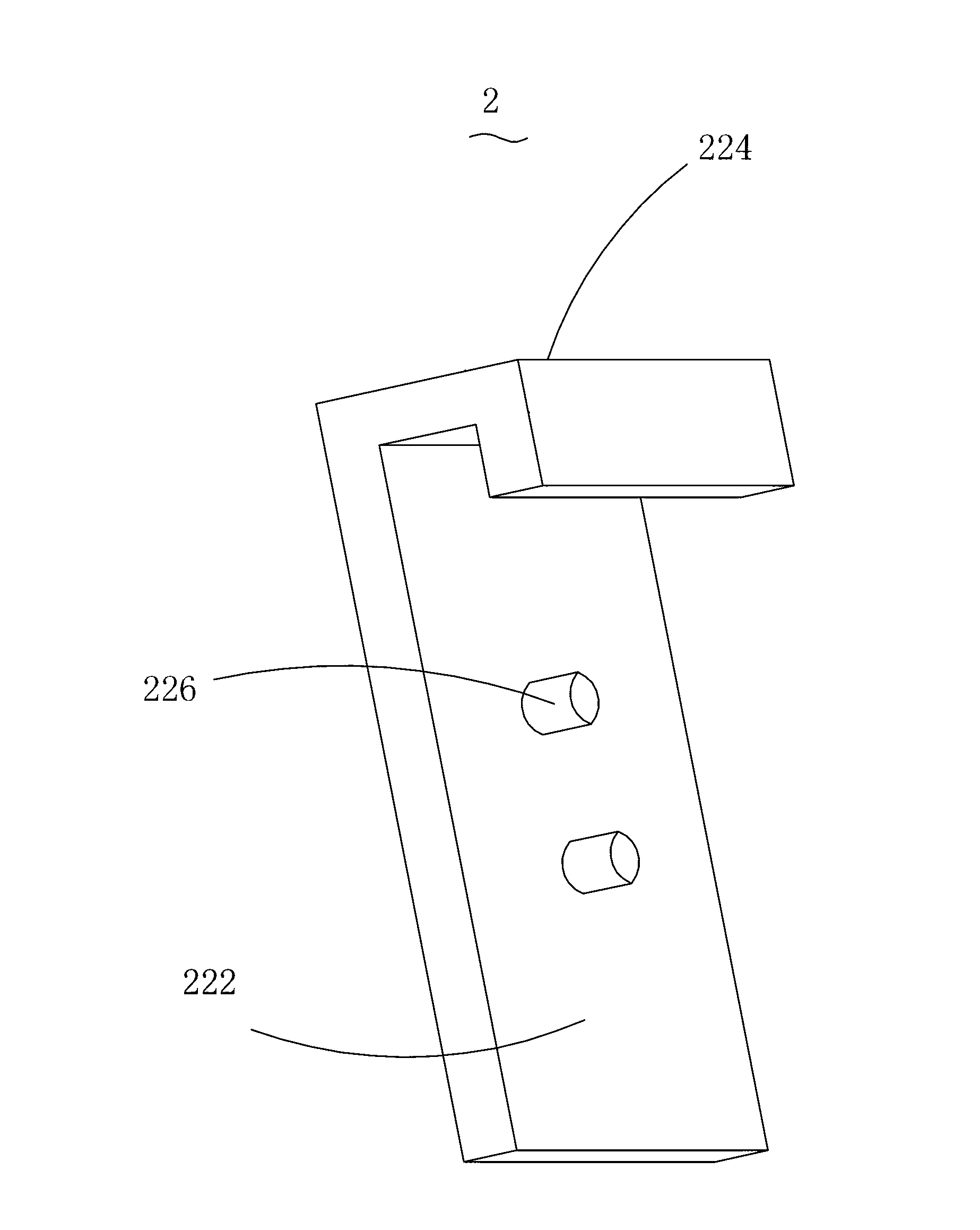

[0029] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0030] see Figure 2 to Figure 5 The liquid crystal glass panel packaging structure of the present invention includes: a packing box (not shown) and several buffer bodies 2 installed in the packing box. The buffer body 2 includes a body 22 and is arranged on the surface of the body facing the liquid crystal glass panel 4 The antistatic layer 24 on the top, the antistatic layer 24 is a silica gel layer, and the silica gel material has good electrical insulation and elasticity. The silica gel on the buffer body 2 has only a thin layer, which can save costs. Not only can effectively prevent the generation of static electricity, but also elastically deform when it is subjected to external force to buffer the external force, and can quickly return ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com