Cleaning agent for papermaking felt

A papermaking felt and cleaning agent technology, applied in the directions of detergent compounding agent, detergent composition, non-ionic surface active compound, etc., can solve the problems of difficulty in maintaining a stable vacuum degree, short service life of the felt, and brittleness of the papermaking felt. , to achieve the effect of low cleaning cost, prolong service life and improve paper quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Take 85% of water by weight percentage (the same below), 0.75% of sodium hydroxide, 0.8% of anhydrous sodium silicate, 0.3% of phenylacryltriazole, 0.55% of ethylenediaminetetraacetic acid, and 10.4% of surfactant (of which twelve Alkylbenzenesulfonic acid 1.8%, nonyl polyoxyethylene ether (NP-10) 8.6%,) and then take 2.2% sodium hydroxide. Put the above raw materials into the stirring tank in the order described under normal temperature and pressure, stir for 20 minutes each time, and finally stir until it is colorless and transparent. This embodiment is tested according to the requirements of Q / OCKX001-2007, and the cleaning rate is 98%.

Embodiment 2

[0037] By weight percentage (the same below) take water 83.3%, sodium hydroxide 0.5%, anhydrous sodium silicate 1.8%, benzotriazole 0.4%, ethylenediaminetetraacetic acid 0.5%, surfactant 11% (of which twelve Alkylbenzene sulfonic acid 1.4%, nonyl polyoxyethylene ether (NP-10) 9.6%); then take 2.5% sodium hydroxide. Put the above raw materials into the stirring tank in the order described under normal temperature and pressure, stir for 20 minutes each time, and finally stir until it is colorless and transparent. This embodiment is tested according to the requirements of Q / OCKX001-2007, and the cleaning rate is 97%.

Embodiment 3

[0039] Take 86.5% of water by weight (the same below), 0.65% of sodium hydroxide, 1.2% of anhydrous sodium silicate, 0.2% of benzotriazole, 0.65% of ethylenediaminetetraacetic acid, and 9.2% of surfactant (of which twelve Alkylbenzene sulfonic acid 1.2%, nonylphenol polyoxyethylene ether (NP-10) 8%,); then take sodium hydroxide 1.6%,. Put the above raw materials into the stirring tank in the order described under normal temperature and pressure, stir for 20 minutes each time, and finally stir until it is colorless and transparent. This embodiment is tested according to the requirements of Q / OCKX001-2007, and the cleaning rate is 97.5%.

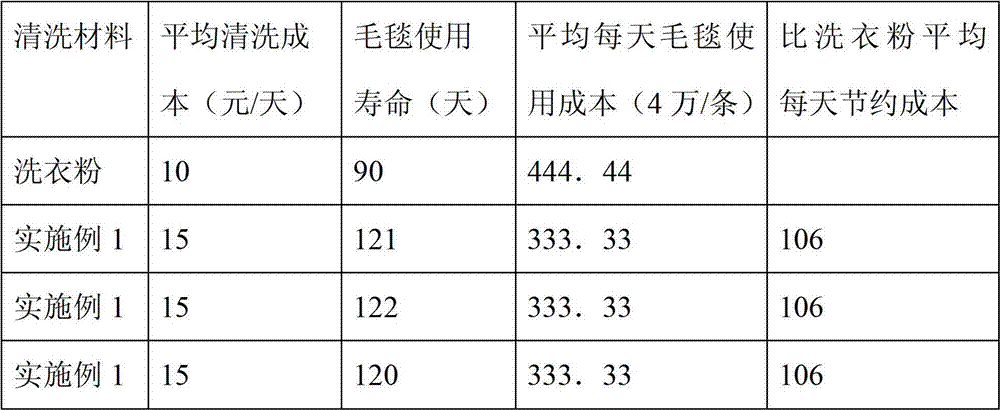

[0040] Cost analysis table before and after use of cleaning agent for papermaking felt

[0041]

[0042] It can be seen from the above table that 1. The cost saving method of the cleaning agent for papermaking blankets is realized by prolonging the service life of the blankets. The average daily cost savings for each production line is 106...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com