HRB700 steel bar and production method thereof

A production method and steel bar technology, applied in HRB700 steel bar and its production field, can solve the problem of waste of alloy elements, and achieve the effects of high elongation, increased structural strength, and easy mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

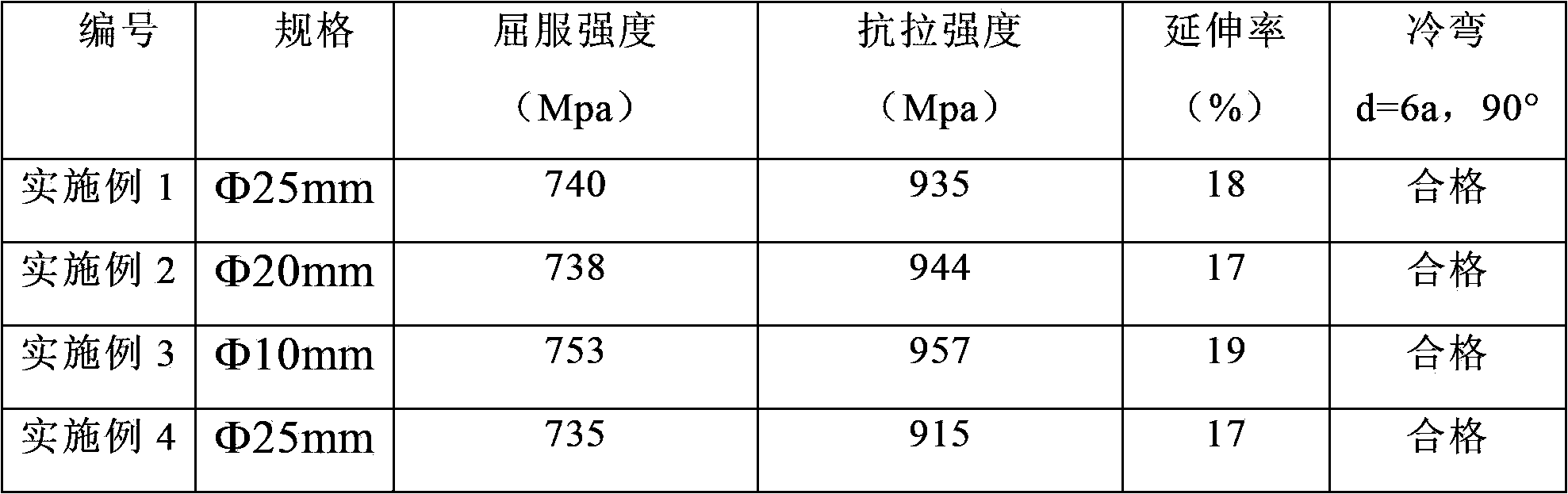

Examples

Embodiment 1

[0028] The method for producing the HRB700 steel bar includes a smelting process, a refining process, a continuous casting process and a rolling process. The specific steps of each process will be described below.

[0029] In the smelting process, the converter or electric furnace is used to smelt molten steel and alloy the ladle. In the ladle alloying step, in addition to adding silicon-manganese and ferrosilicon alloys, vanadium-nitrogen alloys are also added, so that the N content in the molten steel composition reaches 0.021%, and the V content reaches 0.11%.

[0030] In the LF refining process, after the ladle arrives at the refining position, slagging and deoxidation are carried out according to the temperature and slag condition. After the slag turns white, micro-nitrogen alloy silicon nitride is added, so that the N content in the molten steel composition reaches 0.023%, and the white slag remains for 25 minutes. , After the temperature of the ingredients is appropria...

Embodiment 2

[0034] The method for producing the HRB700 steel bar includes a smelting process, a refining process, a continuous casting process and a rolling process. The specific steps of each process will be described below.

[0035] In the smelting process, the converter or electric furnace is used to smelt molten steel and alloy the ladle. In the ladle alloying step, in addition to adding silicon-manganese and ferrosilicon alloys, vanadium-nitrogen alloys are also added, so that the N content in the molten steel composition reaches 0.029%, and the V content reaches 0.10%.

[0036] In the LF refining process, after the ladle reaches the refining position, slagging and deoxidation are carried out according to the temperature and slag condition, and the micro-nitrogen alloy silicon nitride is added after the slag turns white, so that the N content in the molten steel composition reaches 0.031%, and the white slag remains for 20 minutes , After the temperature of the ingredients is approp...

Embodiment 3

[0040]The method for producing the HRB700 steel bar includes a smelting process, a refining process, a continuous casting process and a rolling process. The specific steps of each process will be described below.

[0041] In the smelting process, the molten steel is first smelted in a converter or an electric furnace and alloyed in a ladle. In the ladle alloying step, in addition to silicon-manganese and ferrosilicon alloys, vanadium-nitrogen alloys are also added, so that the N content in the molten steel composition reaches 0.026%, and the V content reaches 0.10%.

[0042] In the LF refining process, after the ladle reaches the refining position, slagging and deoxidation are carried out according to the temperature and slag condition, and the micro-nitrogen alloy silicon nitride is added after the slag turns white, so that the N content in the molten steel composition reaches 0.028%, and the white slag remains for 25 minutes , After the temperature of the ingredients is app...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com