Special measurement system for concurrently measuring ammonia gas and nitrogen oxide in motor tail gas

A nitrogen oxide and measurement system technology, applied in the direction of chemiluminescence/bioluminescence, and analysis through chemical reactions of materials, can solve the problems of high price, high maintenance cost, inconvenient calibration and traceability, etc., and achieve low maintenance cost , high reliability, easy calibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

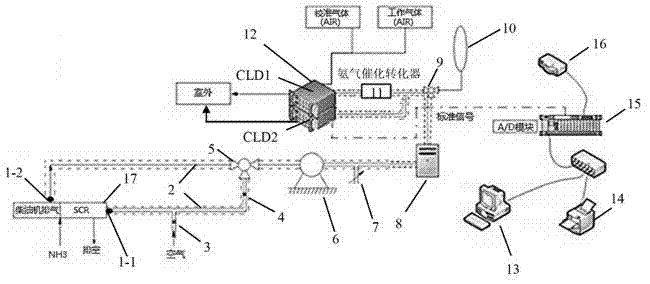

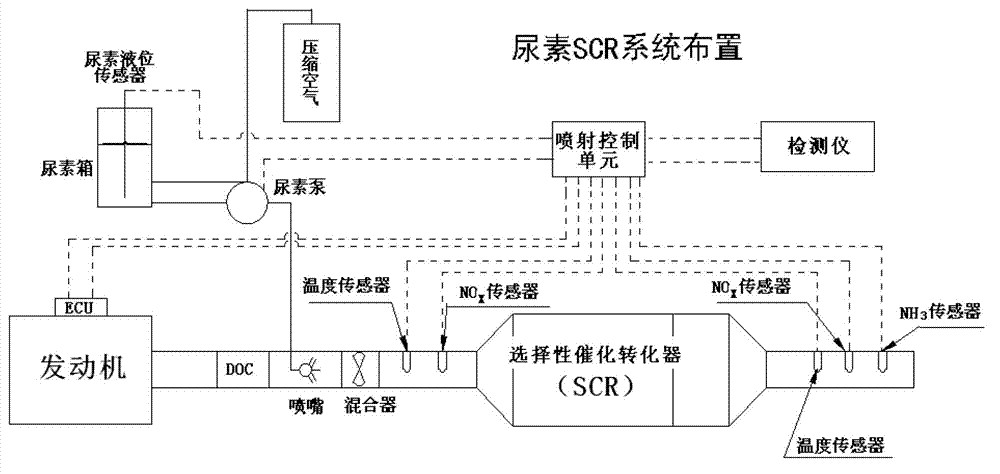

[0052] Such as image 3 Shown, the technical principle of the present invention to residual ammonia concentration measurement in engine exhaust is: for containing a small amount of NO x (NO, NO 2 ), NH 3 The direct sampling method is used to collect the final exhaust gas; the direct sampling gas is diluted and mixed with the air measured by the first Venturi tube (CFV1) to form a diluted exhaust gas; the diluted exhaust gas passes through the second Venturi tube (CFV2) ) after measurement, and then divided into two ways to enter CLD measurement line 1 and CLD measurement line 2, and use the measurement of NO to obtain (NH 3 +NO x ) and NO x (NO, NO 2 ) measured value, where:

[0053] The specific operation of CLD measurement line 1 includes: the diluted exhaust gas first passes through the ammonia oxidation catalytic conversion device, and the NH 3 Converted to NO; detected by CLD1, its NO measurement value should be NO x (NO, NO 2 ) and NH 3 The total concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com