Novel painting reflective film

A reflective film and inkjet technology, applied in the field of reflective film, can solve the problems of light resistance, light fastness, weather resistance, acid and alkali resistance, salt spray resistance, poor flexibility, etc. Sexual, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

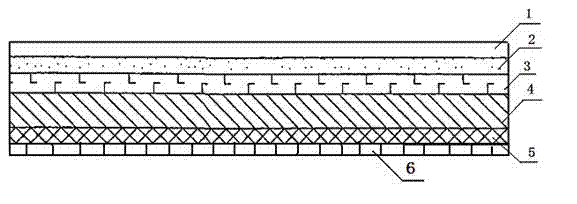

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] Examples such as figure 1 Shown: the present invention relates to a novel inkjet reflective film, which includes a surface protection layer 1, an inkjet ink-absorbing layer 2, an acrylic surface layer 3, a glass bead layer 4, a reflective layer 5 and a release paper 6. Wherein, a release agent is coated between the surface protection layer 1 and the ink-jetting ink-absorbing layer 2, and the ink-jetting ink-absorbing layer 2, the acrylic surface layer 3, the glass bead layer 4, the reflective layer 5 and the release paper 6 pass through Adhesive compounding. In this embodiment, in order to improve weather resistance, acid and alkali resistance, and salt spray resistance, PET film is used as the carrier for the surface protection layer. Then choose the acrylic film with excellent light resistance, light resistance and weather resistance, and con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com