Bus bar for photovoltaic component and component of same

A photovoltaic module and busbar technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve problems such as difficulty in operation and lamination process, poor insulation effect, surface defects on the backplane, etc., to reduce surface defects, The effect of improving reliability and reducing design area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

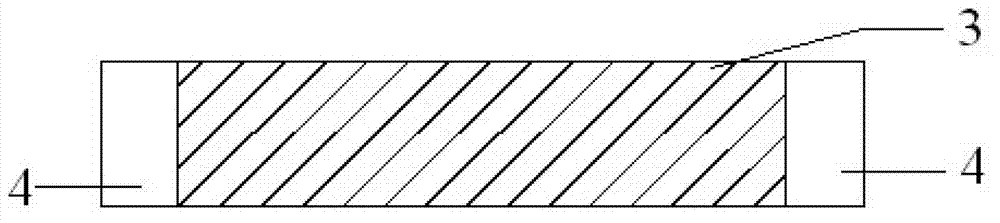

[0020] figure 2 Shown is a bus bar for photovoltaic modules, the insulating area on the surface of the bus bar base material is located in the middle section of the bus bar, the insulating area is covered with an insulating material layer 3, the weldable area is located at both ends of the bus bar, and the weldable area is covered with Weldable layer 4; the insulating material layer 3 is insulating tape, insulating varnish, insulating PET or fluorine film plastic, and the weldable layer 4 is tin. Certainly, the insulation area may also be located only at the intersection 9 area between the bus bars, or the contact area between the bus bar and materials such as batteries and backplanes, or other areas that need to be insulated.

[0021] Taking the insulating varnish as the insulating material layer 3 as an example, the preparation method of the bus bar for photovoltaic modules in this embodiment is as follows: the first step is to cover the insulating area on the surface of th...

Embodiment 2

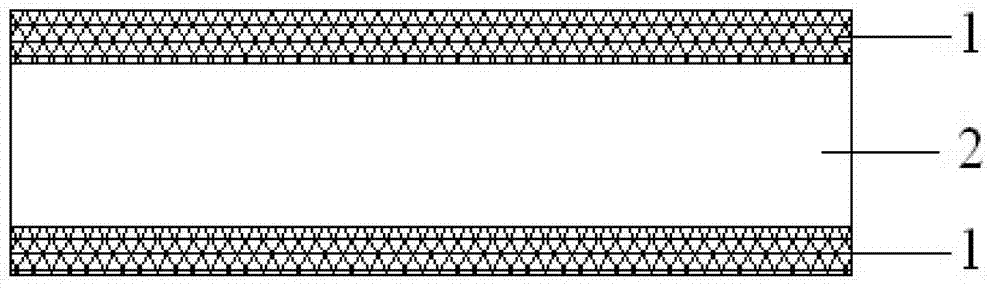

[0023] A bus bar for photovoltaic modules, a schematic diagram of its transverse section Figure 5 It can be seen that the bus bar includes a base material 2, the surface of the base material 2 has a weldable layer 4, and the surface of the weldable layer 4 has an insulating material layer 3; if part of the insulating material layer 3 on the surface of the bus bar needs to be welded, then only It is necessary to scrape off the insulating material layer 3 at the position to be welded. The bus bar of this embodiment can be formed by adding an insulating material layer 3 on the surface of the weldable area of the common bus bar.

Embodiment 3

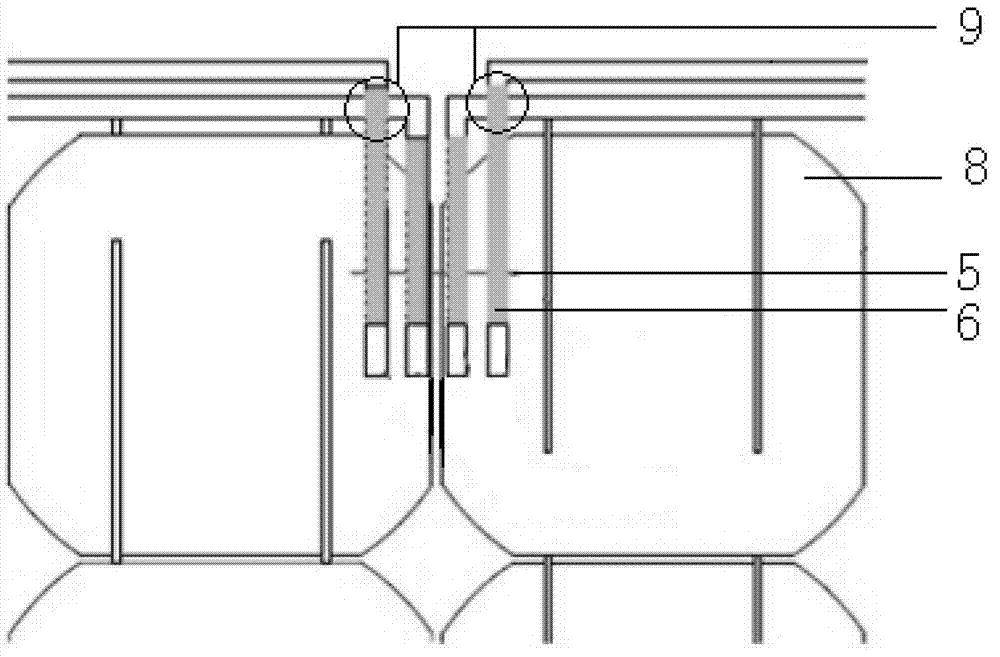

[0025] Such as image 3 As shown, a photovoltaic module, the battery string is packaged between the panel and the back plate 8, the bus bar in the embodiment of the present invention is applied to the photovoltaic module, the battery string is electrically connected through the bus bar and the electric energy is drawn out of the back plate 8, By opening the slit 5 on the back plate 8, not only the lead-out end 6 of the bus bar can be drawn out, but also the insulation effect is good, the surface defect at the slit 5 on the back plate is small, and no additional insulation isolation is required at the intersection 9 of the bus bar Material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com