LTCC (Low Temperature Co-Fired Ceramic) broadband power divider

A power divider and broadband technology, applied in the field of low temperature co-fired ceramic power divider and power divider, can solve the problems of not meeting the miniaturization requirements of radio frequency circuits and occupying a large area, so as to facilitate mass production and manufacturing The effect of low cost and high isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

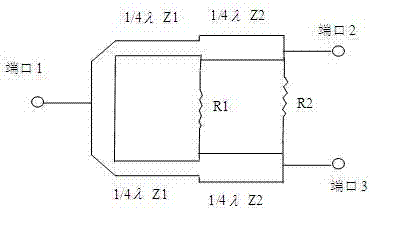

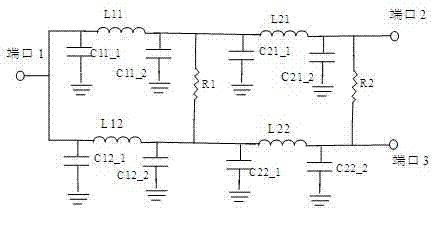

[0034] figure 1 It is the prototype circuit diagram of two-stage Wilkinson broadband power splitter. In the figure, the lengths of the two impedance converters are transmission lines with a quarter wavelength λ, and the characteristic impedances of the transmission lines are Z1 and Z2 respectively. figure 2 is equivalent to a reactance network with lumped parameters figure 1 Two quarter-wavelength transmission lines in . The purpose of the present invention is exactly to realize in as little as possible volume range with LTCC technology figure 2 All capacitors C11_1, C11_2, C12_1, C12_2, C21_1, C21_2, C22_1, C22_2, inductors L11, L12, L21, L22 and resistors R1, R2 in the components.

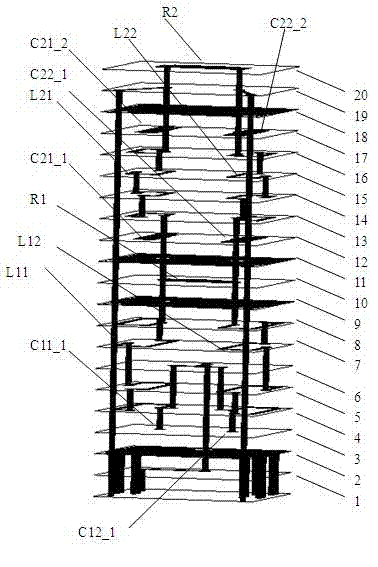

[0035] image 3 shown is implemented using LTCC figure 2 3D structure diagram of all lumped parameter elements in . There are 20 dielectric layers in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com