Resin bag production equipment

A technology for manufacturing equipment and resin bags, which is applied in envelope/bag manufacturing machinery, container manufacturing machinery, flexible container manufacturing, etc. It can solve problems such as insufficient sealing strength, wrinkles in the film, and damage to the appearance, so as to prevent poor welding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below with reference to the embodiments shown in the drawings.

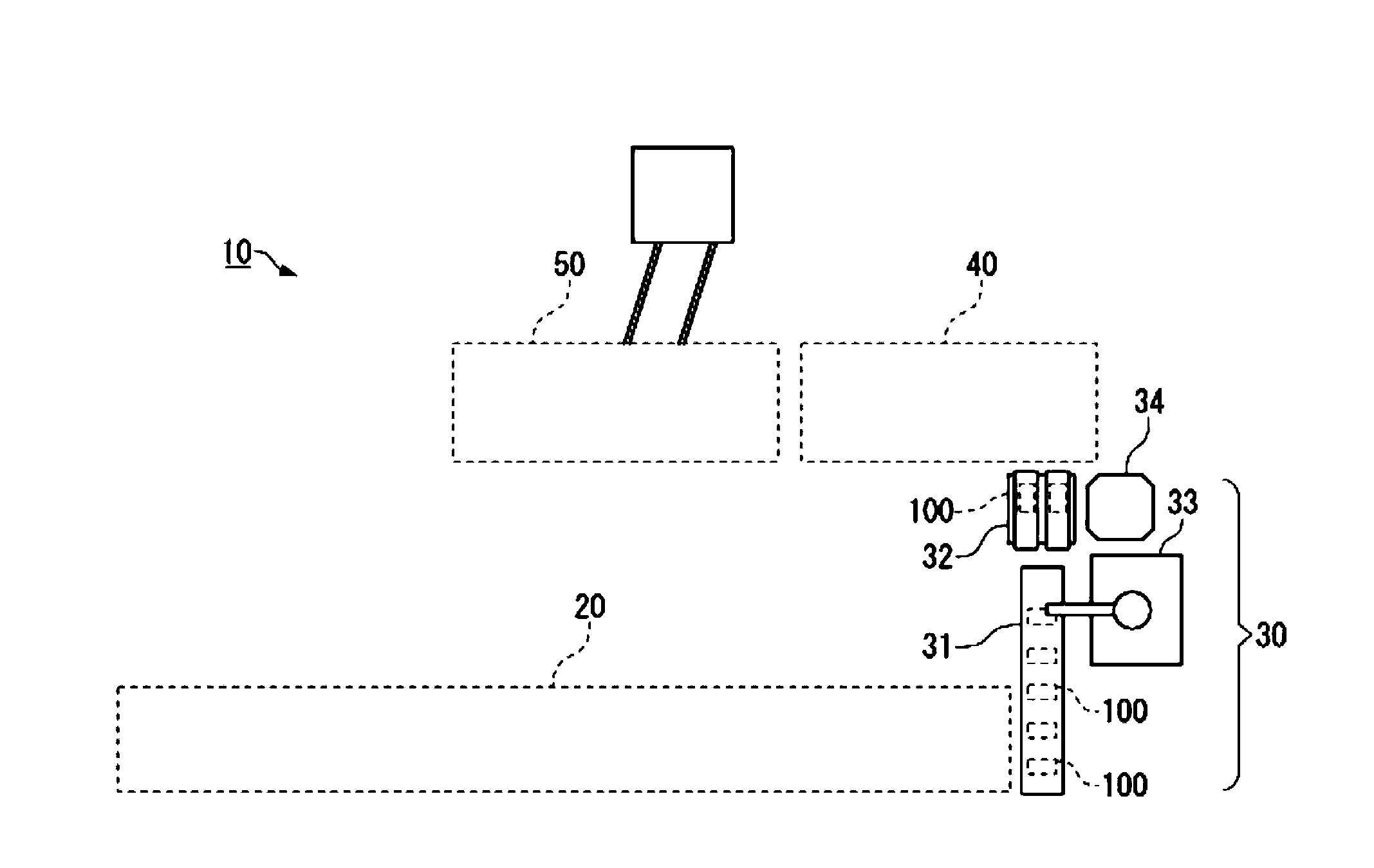

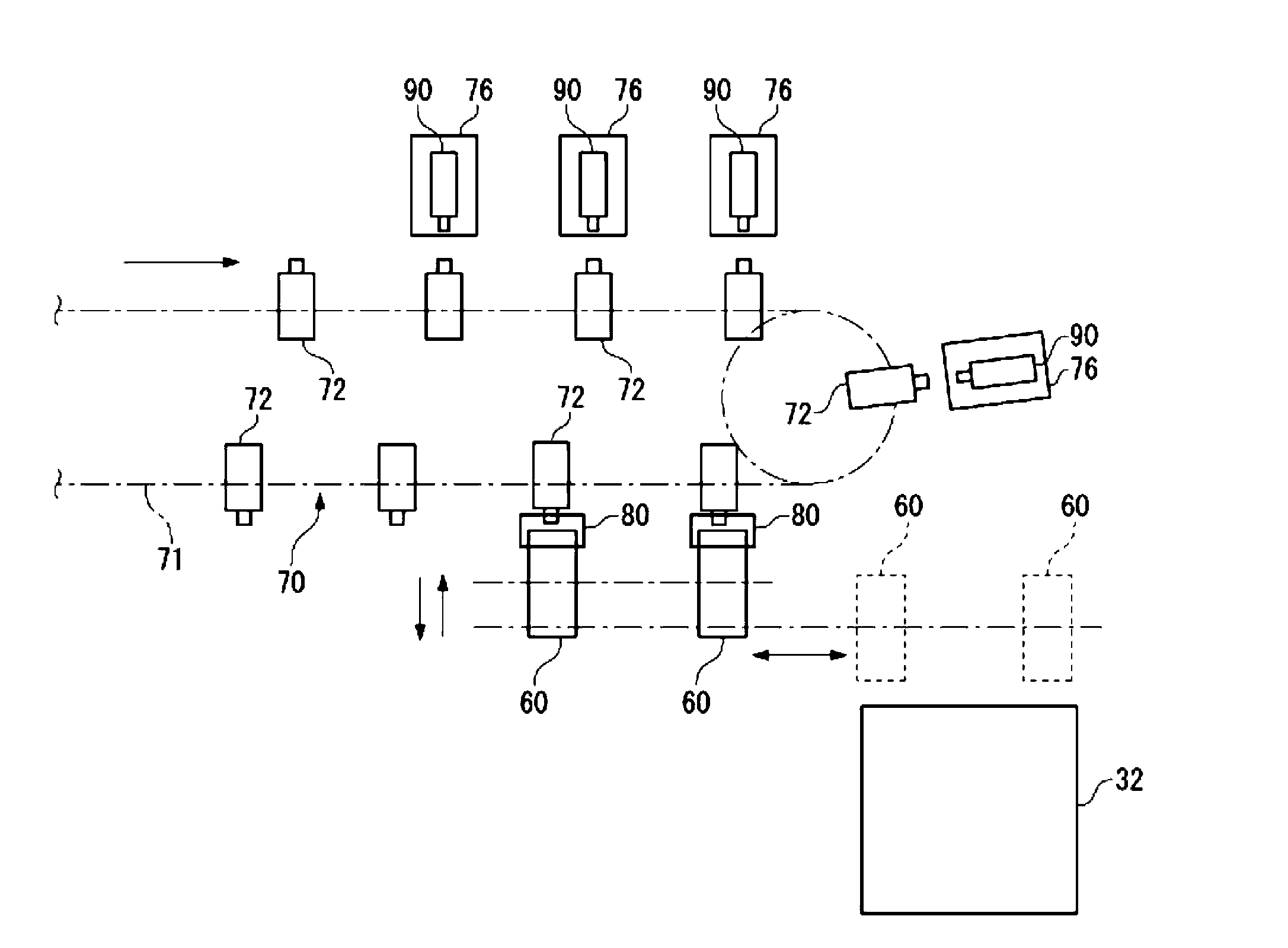

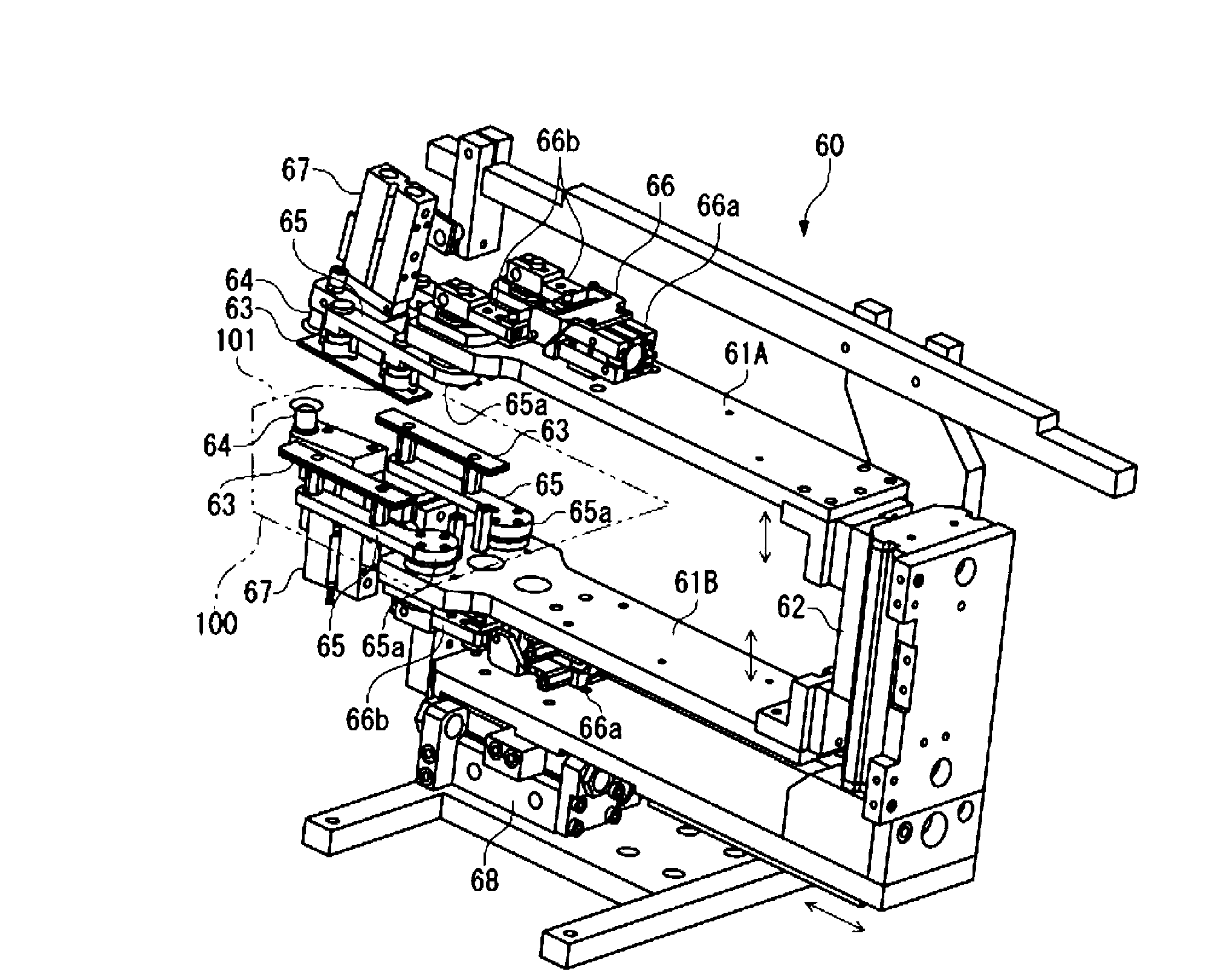

[0045] The resin bag manufacturing equipment 10 of the present embodiment is equipped with: a main body making part 20, which makes the bag main body 100 (refer to image 3 ); the transport unit 30, which transports the bag body 100 made by the body manufacturing unit 20 to the next process; the port installation unit 40, which installs the bag body 100 supplied from the transport unit 30 by welding the port 200; filling The portion 50 fills the bag body 100 with the port 200 attached to the port attachment portion 40 with contents.

[0046] 〈Main body production department 20〉

[0047] The main body manufacturing part 20 is a part which manufactures the bag main body 100 before the port 200 is attached. The main body manufacturing unit 20 manufactures the bag main body 100 by welding and cutting a resin film pulled out from a rolled reel. The bag body 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com