Glass plate package body and method for packaging glass plate stack

A technology of glass plates and laminates, which is applied in packaging, transportation and packaging, and packaging of vulnerable items. It can solve problems such as poor broken line patterns, product defects, and attached flaws or stains, and achieve the effect of reducing cracking defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, preferred embodiments of the glass plate package and the packaging method of the glass plate laminate of the present invention will be described in detail with reference to the drawings.

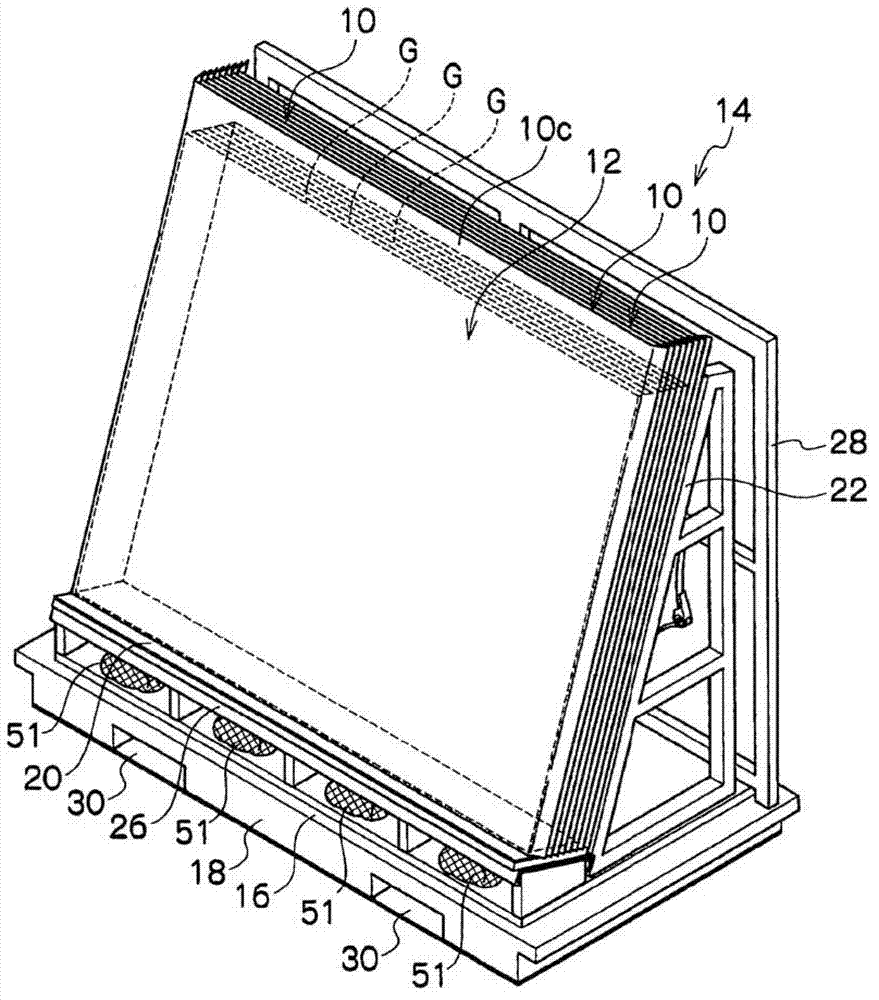

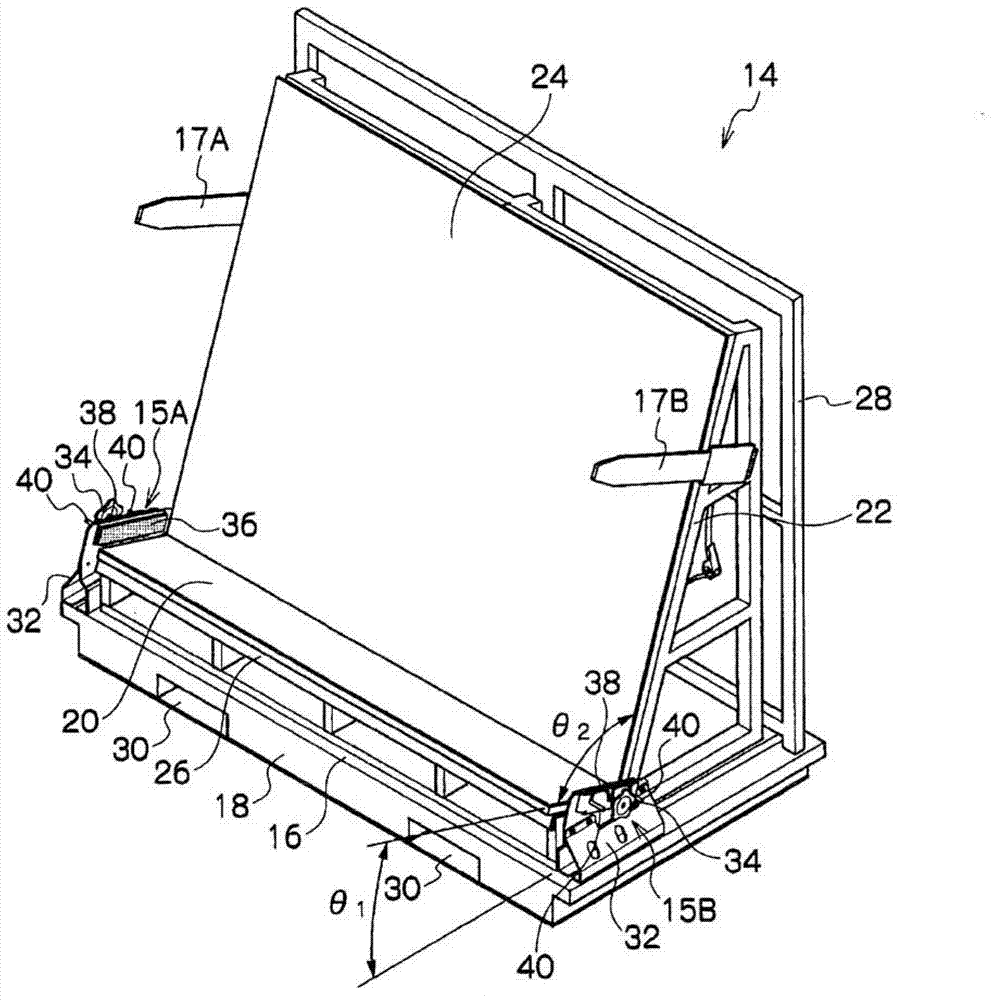

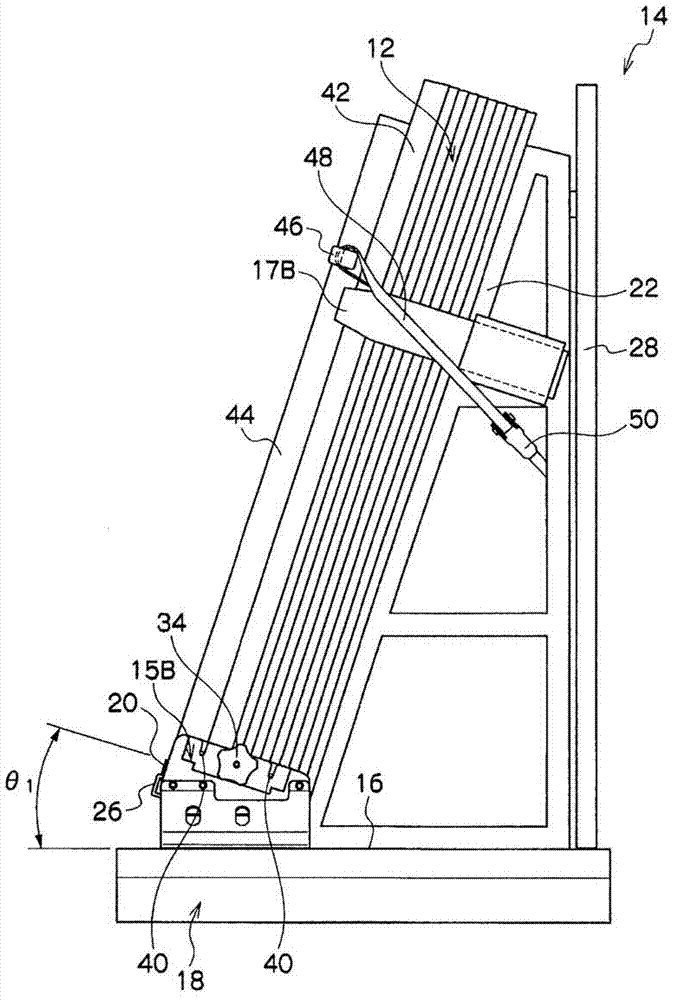

[0045] figure 1 It shows the glass plate laminated body 12 vertically laminated|stacked vertically and obliquely and laminated|stacked through rectangular-shaped paper 10, 10... several sheets of rectangular-shaped glass plates G. And this glass plate laminated body 12 has shown the state packaged by the packaging container 14 of embodiment.

[0046] The said glass plate G is used for the glass substrate for FPDs, such as a liquid crystal display, and its thickness is 0.7 mm or less. In addition, in embodiment, although the paper 10 was illustrated as the sheet|seat interposed between glass plate G and glass plate G, it is not limited to this. For example, a resin film, a resin sheet, and a foamed resin sheet may be used instead of the paper 10 as long as the cushioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com