Al-Cu series aluminum alloy fired mold precision casting deformation control method for severe transition of wall thickness of C-shaped opening

A precision casting, deformation control technology, applied in the direction of casting mold, casting mold composition, manufacturing tools, etc., can solve the problems of low qualification rate, prolonged production cycle, prone to shrinkage, cracks, etc., to prevent deformation, reduce crack defects the effect of the probability of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention will be further described, taking the Al-Cu series high-strength aluminum alloy structure of a certain type of machine as an example, the specific steps of its implementation are as follows:

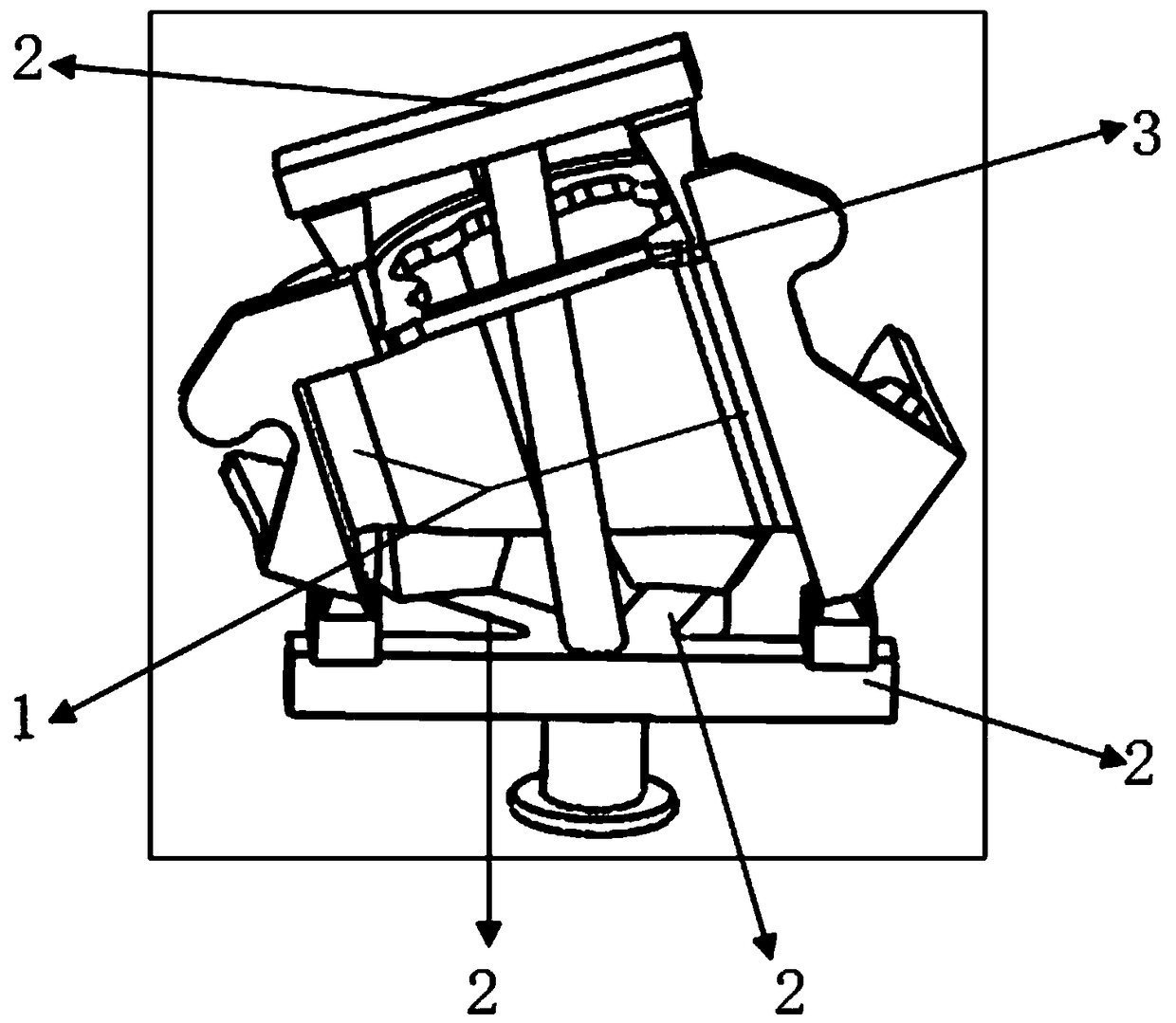

[0018] Step 1: Design the gating system according to the structural characteristics of the casting, such as figure 1 , design a "half-meter-shaped" runner 2, and set anti-deformation ribs 3 at the opening of the thick-walled part, wherein the direction of the runner 2 is consistent with the direction 1 of the "C"-shaped opening of the casting.

[0019] Step 2: Press the wax mold, remove burrs and other defects on the surface of the wax mold, combine the modules according to the gating system determined in step 1, and set anti-deformation ribs 3 at the opening with a wall thickness of 14mm to prevent the wax mold from deforming; the size of the opening meets 272±1.1mm.

[0020] Step 3: After the combination of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com