Bleaching agent particles comprising sodium percarbonate and a bleach activator

A bleach activator, sodium percarbonate technology, applied in the directions of detergent compounding agent, peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, organic per/inorganic per compound composition, etc., It can solve the problems of silo storage obstacles, non-storage, caking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The experiments were carried out in a Mycrolab fluidized bed coater from OYSTAR Hüttlin equipped with a 1 l product container and a three-component nozzle mounted from the bottom, and by subatmospheric pressure in the fluidized bed and 80 °C 35m 3 / h(STP) air is operated as fluidizing gas.

[0068] The binder used was sodium polyacrylate with an average molecular weight of 1900 g / mol in the form of a 45% by weight aqueous solution. The bleach activator used was TAED from Wfk, which was ground in a mortar and mortar, and coarse particles were removed from the bleach activator by sieving through a sieve with a mesh size of 200 μm.

[0069] 400 g of coated sodium percarbonate was filled into a preheated fluid bed coater and heated to a fluid bed temperature of 45°C. Then, the binder solution was sprayed into the fluidized bed through a three-component nozzle at a spraying rate of 3.75 g / min and a spraying pressure of 0.8 bar, resulting in a fluidized bed temperature of 5...

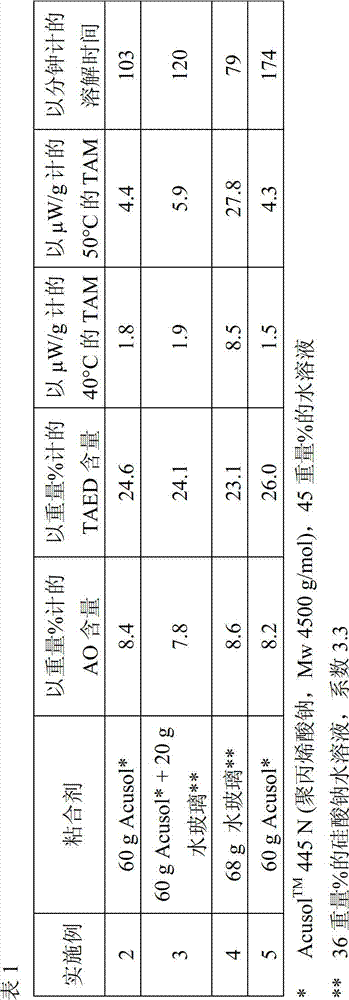

Embodiment 2 to 4

[0072] In each case TAED AC white from Clariant was comminuted at 40 g / portion in a laboratory mill of type A10 from Ika for 30 seconds. 400 g of coated sodium percarbonate were placed in a food processor from Braun, model K3000 type 3210, equipped with a stainless steel container and kneading tools, and at maximum speed, the amount of binder indicated in Table 1 was mixed. Added dropwise, and at the same time, 200 g of pulverized TAED were added at 20 g / portion. When the addition is complete, a further 2 minutes of mixing is carried out, and the mixture is introduced by suction into a fluidized bed coater from OYSTAR Hüttlin, model Mycrolab, equipped with a 1 l product container and built-in from below and having the structure described in DE3806537A1 Two-component nozzle and 35Nm at subatmospheric pressure in the fluidized bed and through 80°C 3 Air at / h[STP] was used as fluidizing gas for operation. Once the temperature in the fluidized bed had increased to 60°C, 250 g o...

Embodiment 5

[0075] Example 2 was repeated, except that 34 g of an aqueous sodium silicate solution with a concentration of 10% by weight and a factor of 3.3 were sprayed through the same nozzle at the same spray rate after spraying the sodium sulfate solution and before post-drying in the fluidized bed.

[0076]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com