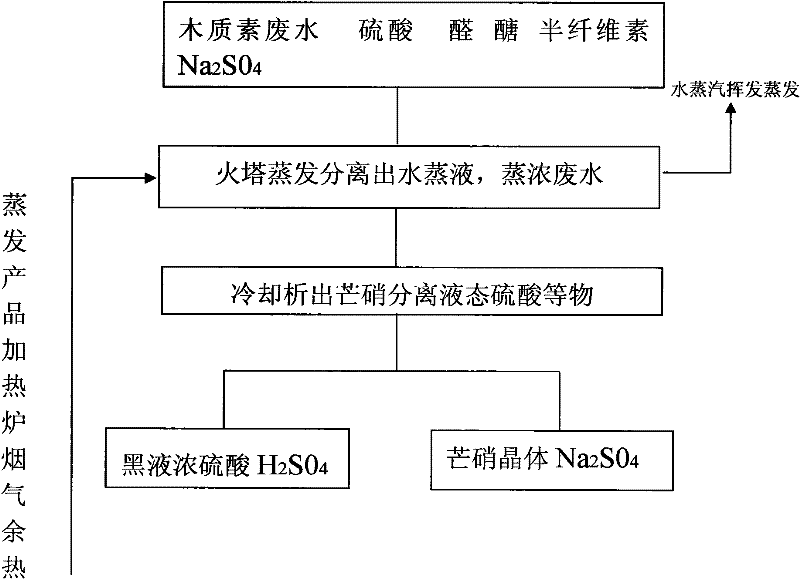

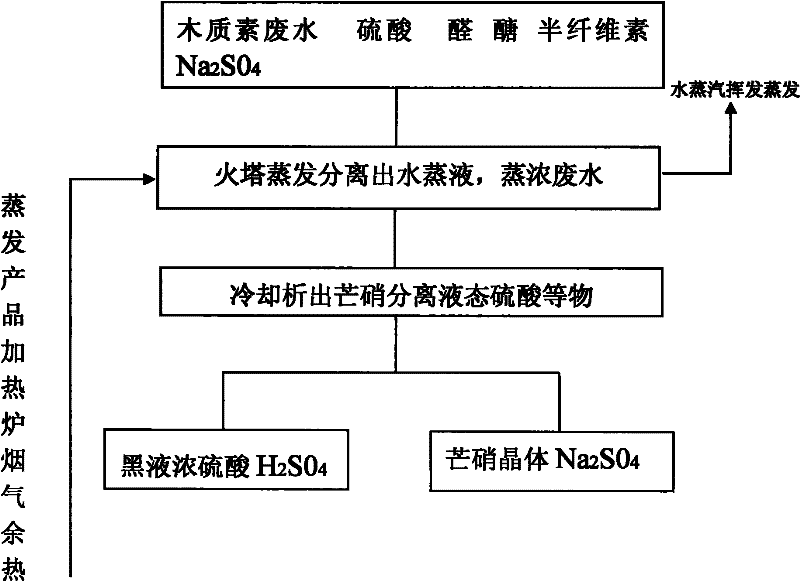

Separation method of sulfuric acid and sodium sulfate in organic sulfonate production wastewater

A separation method and technology of sodium sulfate, applied in chemical instruments and methods, alkali metal sulfite/sulfite, sulfur trioxide/sulfuric acid, etc., can solve the problems of adding lime cost, harming soil, and high salinity of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

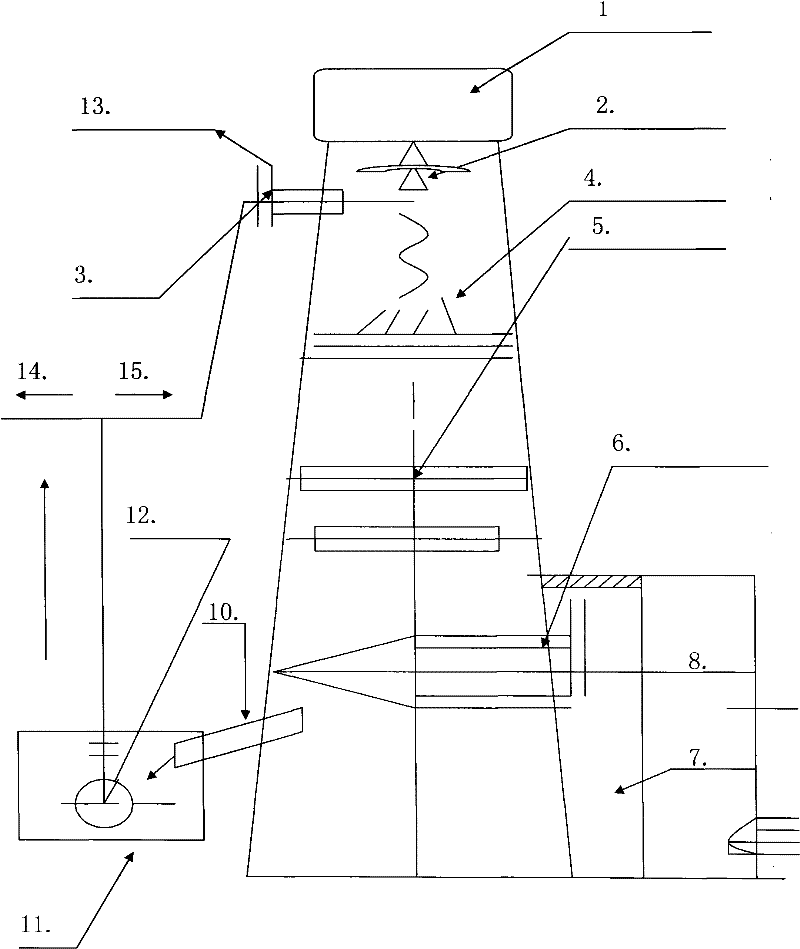

[0024] The waste water enters the tower through the pump feeding pipe 3 through the feeding screw nozzle 13, and falls freely in the form of mist. The feeding screw nozzle 13 is made of acid-proof stainless steel material. The high-pressure flue gas enters the Yanlong gas cabinet, enters the tower through the Yanlong air slot 7 and the air inlet 6 of the induced draft fan, and sends the waste heat flue gas of the evaporator to about 170°C-270°C, directly heating the liquid mist to evaporate, and the superheated steam goes upward with the smoke Entering the chimney tower, through the contact of the multi-layer grid and the filler 5 on the grid, multi-layer overlapping countercurrent contact, multiple heat exchanges, cascading contact heat exchange reactions occur, and water vapor continuously evaporates from the chimney mouth. Soot and liquid droplets flow into the bottom of the flue tower along the wall, and flow into the circulation pool 11 through the return pipe 10 at the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com