Recycling processing technique for industrial wastewater from anhydrous sodium sulphate production

A technology for industrial wastewater and recycling treatment, applied in the directions of alkali metal sulfites/sulfites, alkali metal compounds, inorganic chemistry, etc., can solve the problems of difficult treatment of Yuanmingfen wastewater, and achieve the effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) first soak the Glauber's salt ore in water to obtain crude nitrate, and then put the crude nitrate into the crude nitrate pool,

[0019] (2) add caustic soda and soda ash to the thick nitric water in the crude nitric water pool, separate solid and liquid, obtain refined nitric acid water, and fine nitric acid water is squeezed into the refined nitric water pool,

[0020] (3) heating refined nitric water, crystallization obtains sodium sulfate product, and solid-liquid separation obtains waste residue and waste water,

[0021] (4) The waste residue is backfilled into the mine, and the waste water is returned to step (1) for flooding of Glauber's salt mine.

[0022] In the present invention, the hot wastewater after the crystallization of refined nitric acid is used to return to the leaching of Glauber's salt ore, realizing zero discharge of wastewater, and because the temperature of the wastewater is relatively high, it is more conducive to mineral leaching when used...

Embodiment 2

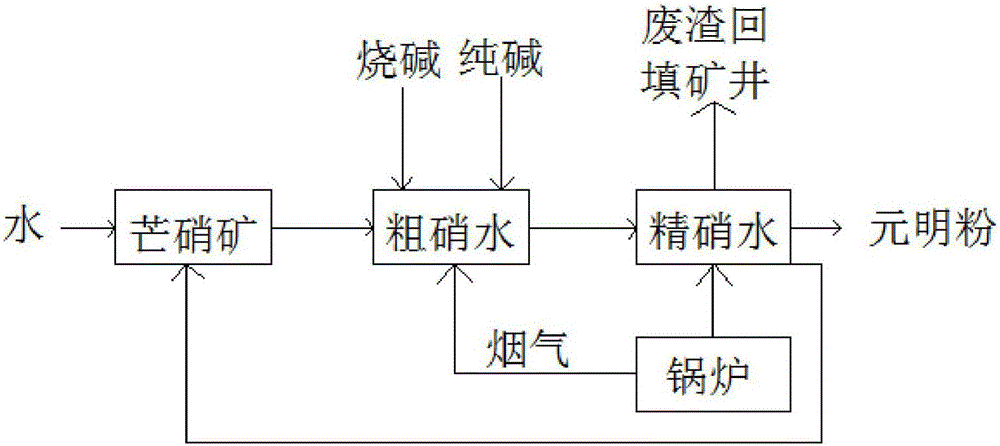

[0025] Such as figure 1 as shown,

[0026] (1) first soak the Glauber's salt ore in water to obtain crude nitrate, and then put the crude nitrate into the crude nitrate pool,

[0027] (2) add caustic soda and soda ash to the thick nitric water in the crude nitric water pool, separate solid and liquid, obtain refined nitric acid water, and fine nitric acid water is squeezed into the refined nitric water pool,

[0028] (3) Use the boiler to generate high-temperature steam to heat the refined nitric acid water, crystallize to obtain the sodium sulfate product, and separate solid and liquid to obtain waste residue and waste water,

[0029] (4) The waste residue is backfilled into the mine, and the waste water is returned to step (1) for flooding of Glauber's salt mine.

Embodiment 3

[0031] Such as figure 1 as shown,

[0032] (1) first soak the Glauber's salt ore in water to obtain crude nitrate, and then put the crude nitrate into the crude nitrate pool,

[0033] (2) add caustic soda and soda ash to the thick nitric water in the crude nitric water pool, separate solid and liquid, obtain refined nitric acid water, and fine nitric acid water is squeezed into the refined nitric water pool,

[0034] (3) Use the boiler to generate high-temperature steam to heat the refined nitric acid water, crystallize to obtain the sodium sulfate product, and separate solid and liquid to obtain waste residue and waste water,

[0035] (4) The waste residue is backfilled into the mine, the waste water is returned to step (1) for flooding of Glauber's salt ore, and the tail gas of the boiler is passed through the crude nitrate water to be used for heating the crude nitrate water in step (2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com