Offline cleaning method for removing pollutants of SPG (shirasu porous glass) membrane used in biological wastewater treatment

A biological treatment and membrane fouling technology, applied in the field of sewage treatment, can solve the problems such as the loss of the ability of SPG membrane to generate micro-bubbles, the difficulty of stable operation of the wastewater treatment process, and the surface pollution of SPG membrane.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

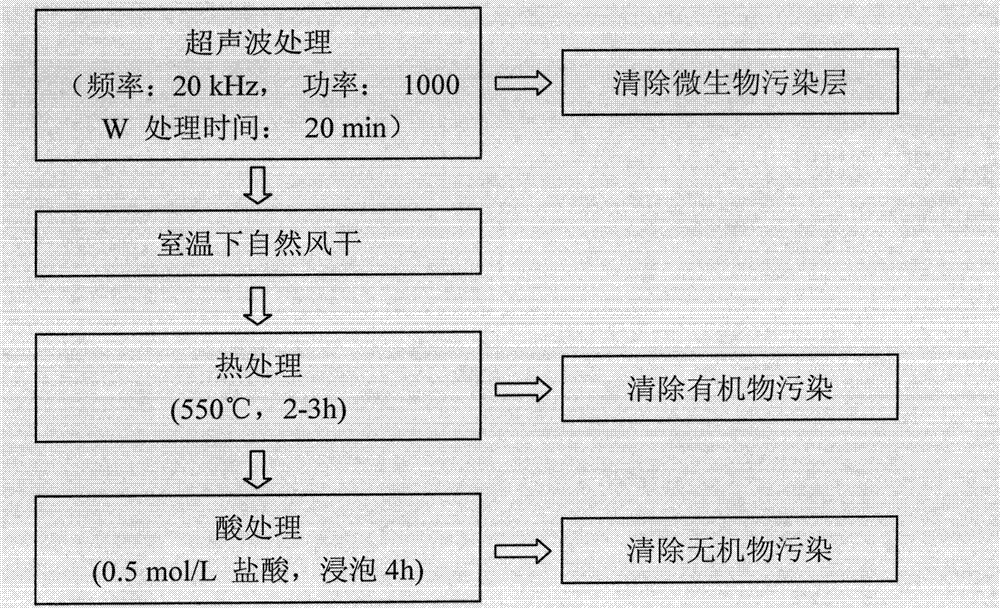

[0024] next head combination figure 1 The schematic diagram shown is a detailed description of the specific embodiment of the present invention.

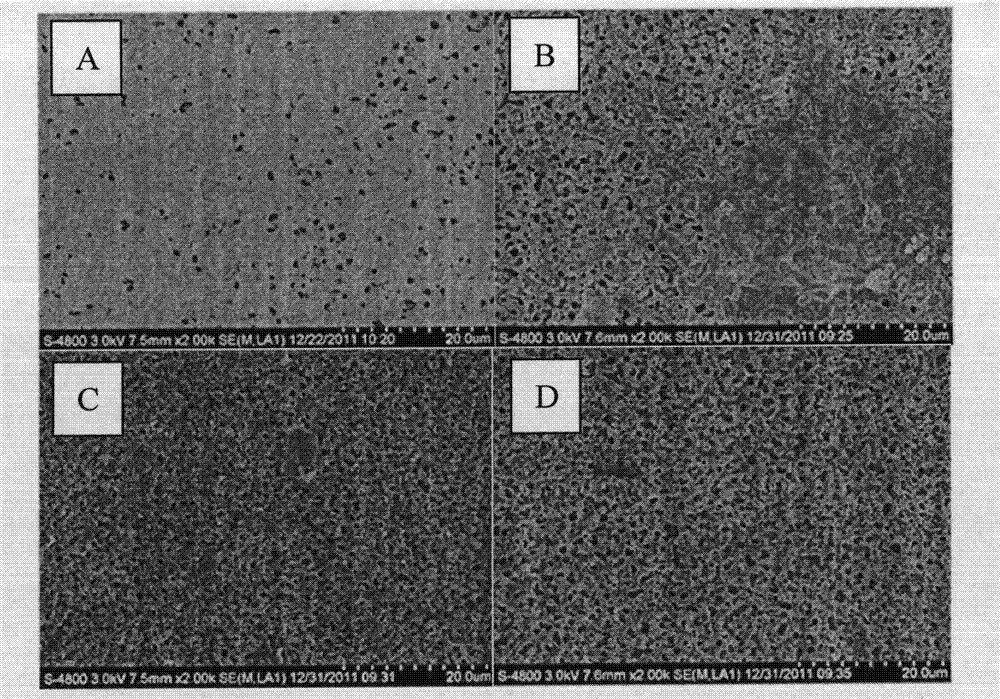

[0025] In the biofilm reactor with fixed soft fiber carrier, SPG membrane microbubble aeration technology is used for microbubble aeration to treat domestic sewage. After the SPG membrane is polluted, ultrasonic treatment is first used for 20 minutes to remove the microbial contamination layer. The ultrasonic frequency is 20kHz , with a power of 1000W, then air-dried naturally at room temperature, heated to 550°C for 2-3 hours to remove organic pollution; then soaked in 0.5mol / L hydrochloric acid for 4 hours to remove inorganic pollution, using this off-line method for cleaning, SPG Membrane fouling is completely removed, microbubble generation ability is basically restored, and long-term stable operation of the overall wastewater treatment system can be realized. Off-line cleaning method of the present invention is to the cleaning...

Embodiment 2

[0027] In the biofilm reactor with suspended spherical carrier, the SPG film micro-bubble aeration technology is used for micro-bubble aeration to treat domestic sewage. After the SPG film is polluted, it is cleaned by the same off-line method as in the example, and the SPG film pollution is completely removed. , the ability to generate microbubbles is basically restored, and the long-term stable operation of the overall wastewater treatment system can be realized. After adopting the off-line method of the present invention to remove SPG membrane fouling, the ability to generate microbubbles and the efficiency of oxygen mass transfer can be fully restored. Taking the dissolved oxygen concentration as the macro index, after membrane fouling, the dissolved oxygen concentration drops from 5mg / L to below 2mg / L, and after the membrane fouling is removed by the off-line cleaning method of the present invention, the dissolved oxygen concentration returns to 4.5-5.0mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com