Insect-resistant polymer composite and preparation method thereof

A composite material and polymer technology, applied in the field of polymer insect-proof composite materials and their preparation, can solve the problems of shortening the service life of wooden floors, the floor being susceptible to moth-eaten, etc., and achieve the effect of preventing mildew and rot.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

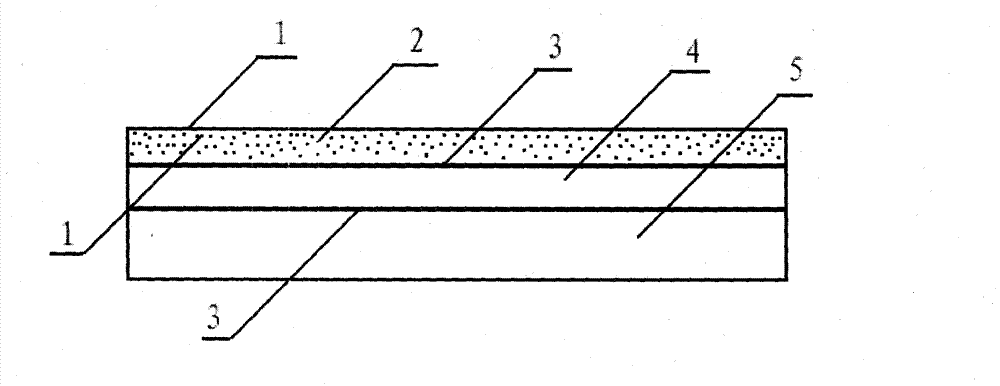

[0014] Embodiment 1: The polymer insect-proof composite material of this embodiment is composed of an anti-corrosion and insect-proof agent layer 1, a polypropylene non-woven fabric layer 2, a polyethylene adhesive layer 3, a polyester aluminized film 4 and an EPE foam sheet layer. 5 composition, the anti-corrosion and insect repellent layer 1 is coated or invaded on the polypropylene non-woven fabric layer 2 (non-woven fabric), between the lower surface of the polypropylene non-woven fabric layer 2 and the upper surface of the polyester aluminized film layer 4. A polyethylene adhesive layer 3 is arranged between, and a polyethylene adhesive layer 3 is arranged between the lower surface of the polyester aluminized film 4 and the EPE foam sheet layer 5 to form a polymer insect-proof composite material.

specific Embodiment approach 2

[0015] Specific embodiment 2: The steps of the preparation method of a polymer insect-proof composite material described in this embodiment are as follows:

[0016] Step 1. Laminate the upper surface and the lower surface of the polyester aluminized film with a layer of polyethylene on the laminating machine, and cool to shape;

[0017] Step 2, laying the EPE foam sheet layer below;

[0018] Step 3, laminating the lower surface of the polyester aluminized film of polyethylene on the upper surface and the lower surface of the step 1 with the upper surface of the EPE foam sheet layer;

[0019] Step 4, laminating the lower surface of the polypropylene non-woven fabric layer with a layer of polyethylene coated on the upper surface of the polyester aluminized film;

[0020] Step 5. The above-mentioned laminate is then placed on a heat sealing machine, and the polymer composite material is formed under the conditions of a temperature of 140-160° C. and a pressure of 0.4-0.5 MPa;

...

specific Embodiment approach 3

[0022] Embodiment 3: The anti-corrosion and insect-repellent agent layer 1 described in this embodiment is coated with Boyi brand termite-killing water agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com