Duckweed isolating type quantitative floating water outlet device

A technology of water outlet and duckweed, which is applied in the feeding/discharging device of sedimentation tank, grease/oily substance/float removal device, flocculation/sedimentation water/sewage treatment and other directions, which can solve the problem of fine-tuning the drainage volume and high maintenance cost. , slideway and sleeve jamming and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The duckweed-separated quantitative floating water outlet device of the present invention will be further described below in conjunction with the embodiments

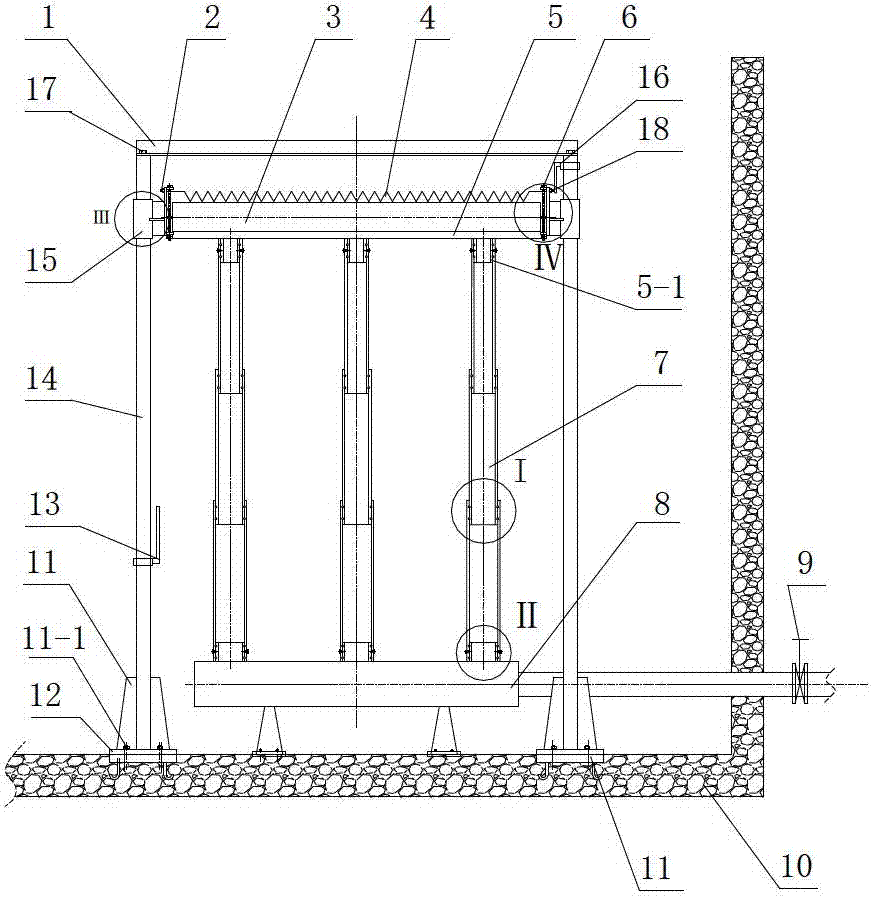

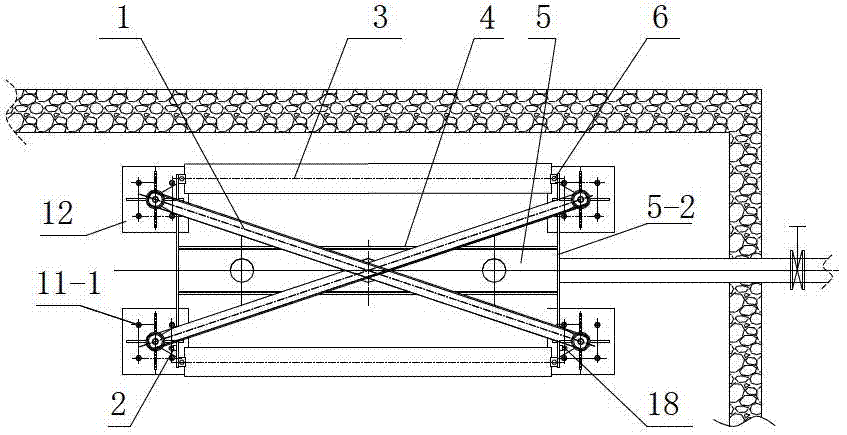

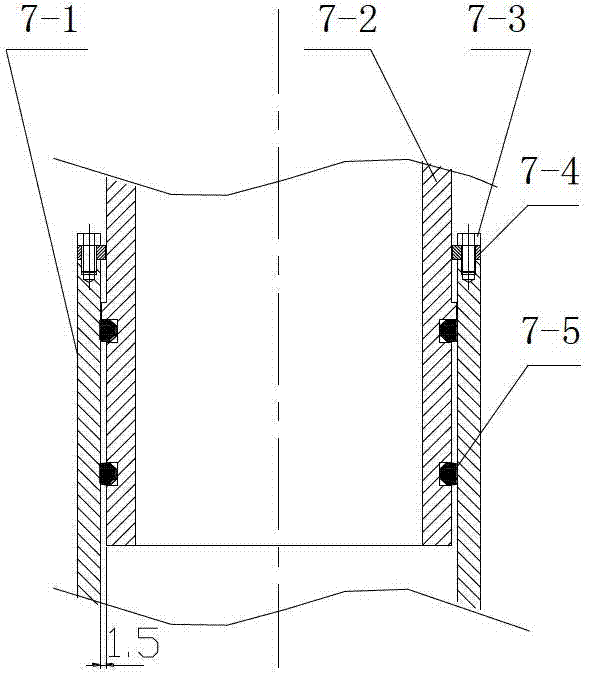

[0045] The duckweed-separated quantitative floating water outlet device includes: fixed frame 1 on the slideway, inductive proximity switch a2, buoy 3, water distribution weir plate 4, drainage box 5, buoy adjustment device 6, drainage telescopic pipe 7, water collection pipe 8, electric Valve 9, sedimentation tank 10, embedded mounting seat 11, bracket slide base 12, lower limiter 13, bracket slideway 14, drainage tank guide sleeve 15, upper limiter 16, bolt 17, inductive proximity switch b18, drainage Tank outlet pipe 5-1, drainage tank end plate 5-2, buoy adjustment bolt 6-1, buoy adjustment upper support 6-2, adjustment tightening nut 6-3, buoy support nut 6-4, buoy adjustment lower support Seat 6-5, spring washer 6-6, anti-loosening nut 6-7, telescopic tube a7-1, telescopic tube b7-2, gland bolt 7-3, gland 7...

Embodiment 2

[0052] The installation method of the duckweed-separated quantitative floating water outlet device includes the fixed frame 1 on the slideway, the inductive proximity switch a2, the buoy 3, the water distribution weir plate 4, the drainage box 5, the buoy adjustment device 6, the drainage telescopic pipe 7, the water collection pipe 8. Electric valve 9, sedimentation tank 10, embedded mounting seat 11, bracket slide base 12, lower limiter 13, bracket slideway 14, drainage box guide sleeve 15, upper limiter 16, bolt 17, inductive proximity switch b18. Drainage tank outlet pipe 5-1, drainage tank end plate 5-2, buoy adjustment bolt 6-1, buoy adjustment upper support 6-2, adjustment tightening nut 6-3, buoy support nut 6-4, buoy Adjust the lower support 6-5, spring washer 6-6, anti-loosening nut 6-7, telescopic tube a7-1, telescopic tube b7-2, gland bolt 7-3, gland 7-4, O-ring 7-5. The installation of the set bolt 7-6, the water collection pipe joint 8-1, the water collection pip...

Embodiment 3

[0066] The installation and debugging method of the duckweed-separated quantitative floating water outlet device includes the fixed frame 1 on the slideway, the inductive proximity switch a2, the buoy 3, the water distribution weir plate 4, the drainage box 5, the buoy adjustment device 6, the drainage telescopic pipe 7, Water collection pipe 8, electric valve 9, sedimentation tank 10, embedded mounting seat 11, bracket slide base 12, lower limiter 13, bracket slideway 14, drainage box guide sleeve 15, upper limiter 16, bolt 17, inductive Proximity switch b18, drainage tank outlet pipe 5-1, drainage tank end plate 5-2, float adjustment bolt 6-1, float adjustment upper support 6-2, adjustment tightening nut 6-3, float support nut 6-4 , Lower support for buoy adjustment 6-5, spring washer 6-6, anti-loosening nut 6-7, telescopic tube a7-1, telescopic tube b7-2, gland bolt 7-3, gland 7-4, O-type The installation of the sealing ring 7-5, the set bolt 7-6, the water collection pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com