Low-water-absorption reinforced polyamide compound and preparation method thereof

A low water absorption, polyamide technology, applied in the field of low water absorption reinforced polyamide composites and their preparation, can solve the problems of poor rigidity, decreased strength, decreased rigidity, etc., and achieves low production cost, good dimensional stability, The effect of high product forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

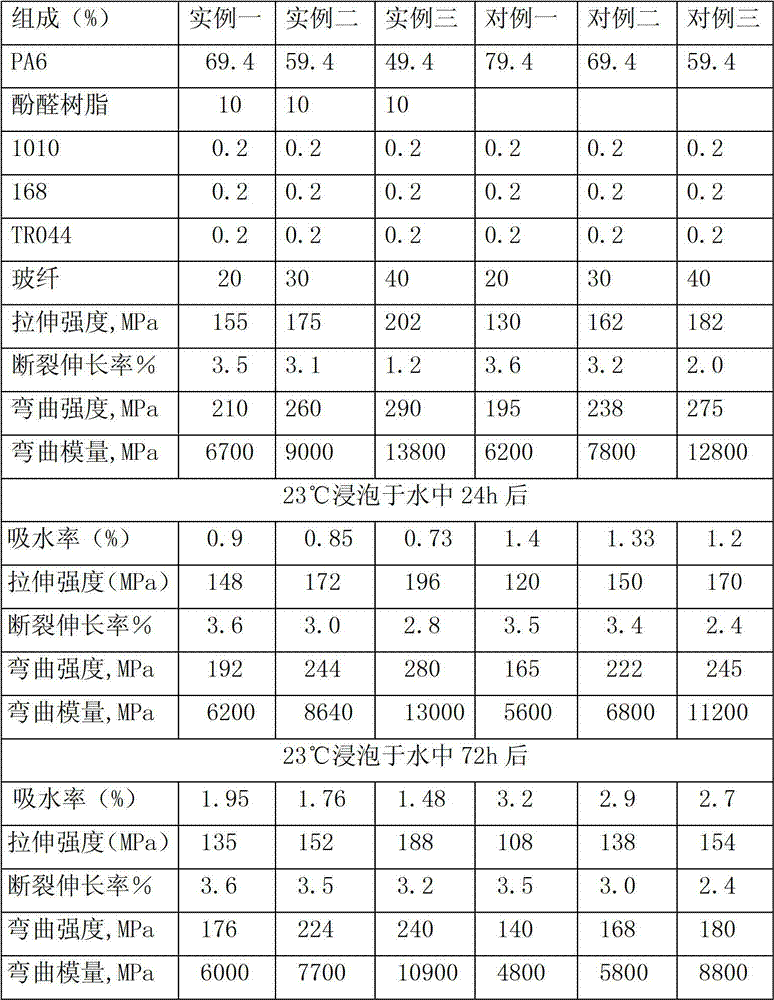

Examples

Embodiment 1

[0021] A kind of preparation method of low water absorption reinforced polyamide compound, it has the following steps:

[0022] (1) In terms of weight percentage, after accurately weighing 69.4% polyamide, 10% phenolic resin, 10100.2% antioxidant, 0.2% antioxidant 168 and 0.2% lubricant, pre-dry at 90-100°C;

[0023] (2) Put the dried material above into a high-speed mixer for dry mixing for 1 to 4 minutes, then feed the mixed material into a twin-screw extruder, and add 20% glass fiber to the side feeding port of the twin-screw extruder, Then the above-mentioned total mixture is melted and extruded by a twin-screw extruder, cooled, dried, and pelletized to obtain the finished product;

[0024] The parameters of each section of the low water absorption reinforced polyamide compound on the twin-screw extruder are set as follows: the temperature of the first zone is 200°C, the temperature of the second zone is 230°C, the temperature of the third zone is 230°C, the temperature of...

Embodiment 2

[0026] A method for preparing a low water absorption reinforced polyamide composite, the preparation steps and origin of the materials are the same as in Example 1, and the formula is: polyamide 59.4%, phenolic resin 10%, antioxidant 1010 0.2%, antioxidant 168 0.2 %, lubricant 0.2% and glass fiber 30%.

Embodiment 3

[0028] A method for preparing a low water absorption reinforced polyamide composite, the preparation steps and origin of the materials are the same as in Example 1, the formula is: polyamide 49.4%, phenolic resin 10%, antioxidant 1010 0.2%, antioxidant 168 0.2 %, lubricant 0.2% and glass fiber 40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com