Micro-jet electroforming nozzle

A technology of jet electroforming and nozzle, which is applied in the direction of electroforming and electrolysis, can solve the problems of reducing the shape quality and performance of electroforming layers/parts, restricting the deepening application of jet electroforming technology, and large equal-diameter shooting range, etc., to achieve reduction The effect of processing cost, high processing accuracy and increasing the equal-diameter range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

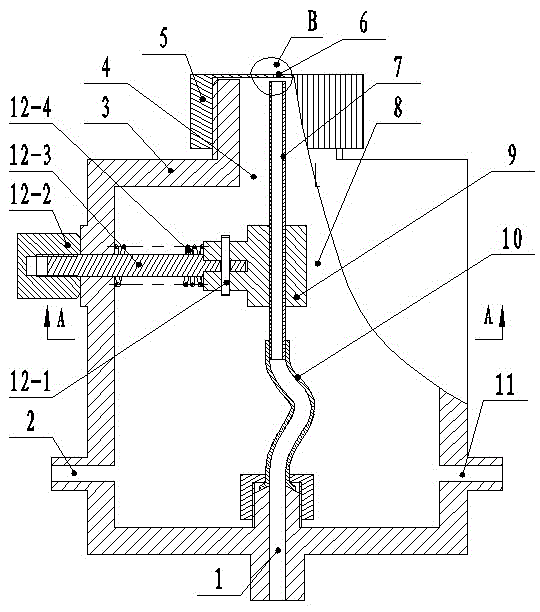

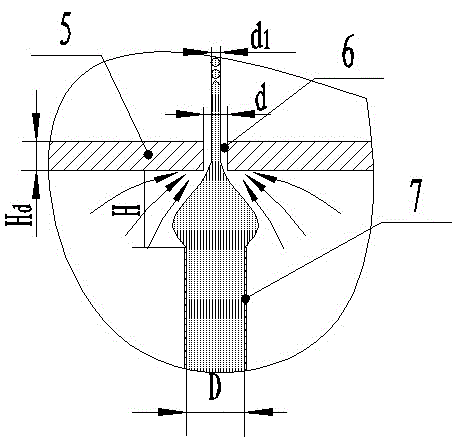

[0027] Such as figure 1 , figure 2 with image 3 As shown, a micro-jet electroforming nozzle of the present invention includes a nozzle body 3 having a cavity 8, the nozzle body 3 is provided with a liquid inlet port 1 and an air inlet port 2, and the cavity 8 of the nozzle body 3 is provided with The nozzle pipe 7 connected to the liquid inlet interface 1 is detachably sealed with a nozzle cap 5 outside the nozzle 4, and the nozzle cap 5 is provided with a diversion hole 6, and the center lines of the nozzle 4, the nozzle pipe 7 and the diversion hole 6 coincide. There is a gap between the inlet end face of the diversion hole 6 and the outlet end face of the nozzle 7, and the nozzle body 3 is provided with a conductive fine-tuning mechanism that extends into the cavity 8 and is connected with the nozzle 7, and the cavity 8 is filled with Inert gas under pressure.

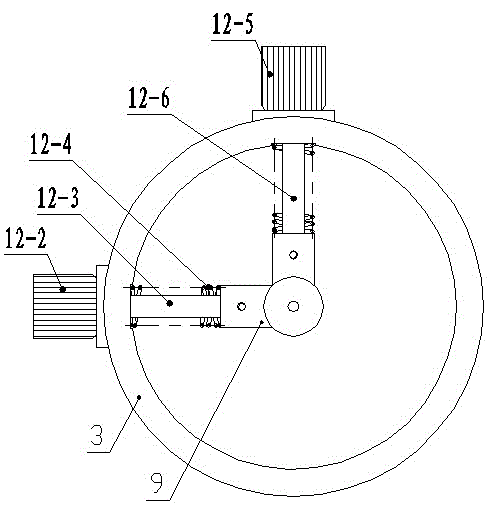

[0028]The conductive centering fine-tuning mechanism includes a clamping body 9, an X-direction terminal 12-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com