Method for evaluating forms, sizes and distributions of free cementites in aluminum killed steel

A technology of free cementite, aluminum killed steel, used in the analysis of materials, preparation of test samples, material analysis using wave/particle radiation, etc. Stamping formability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

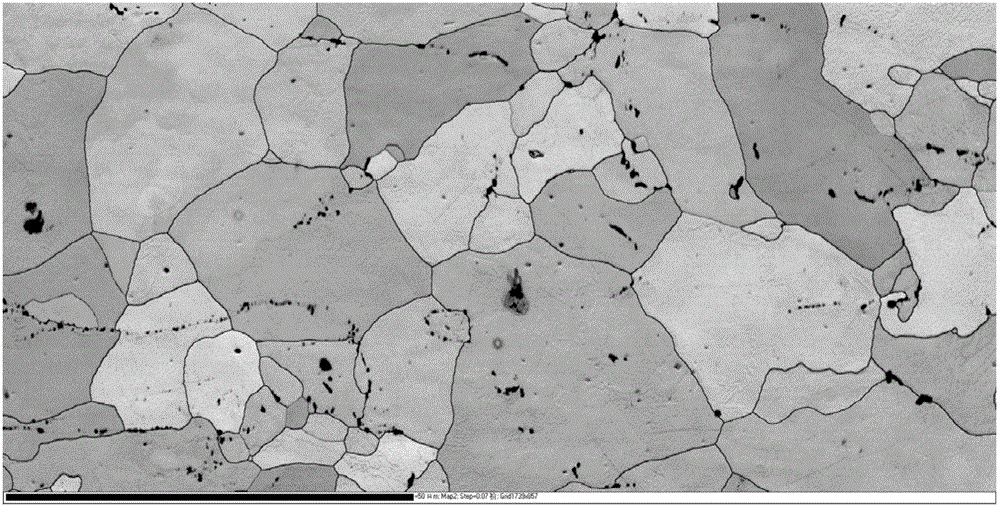

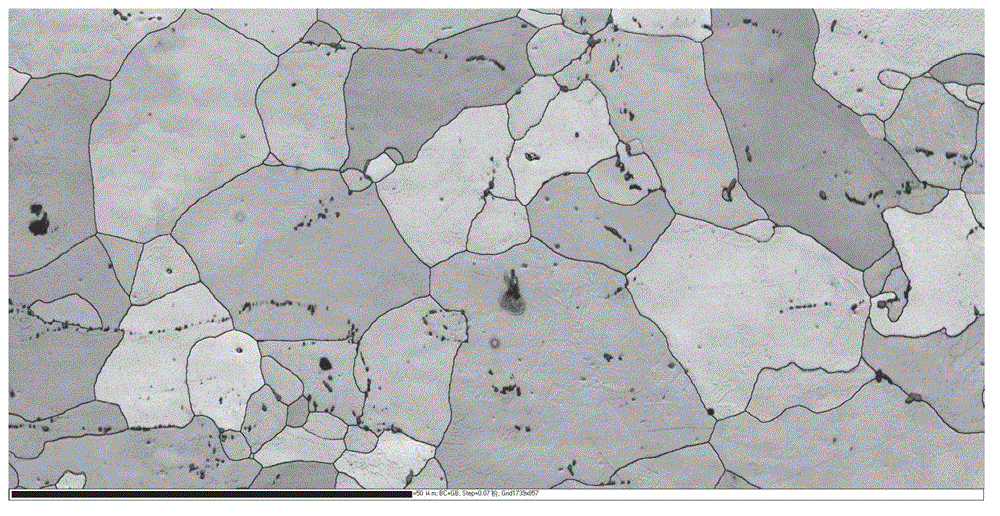

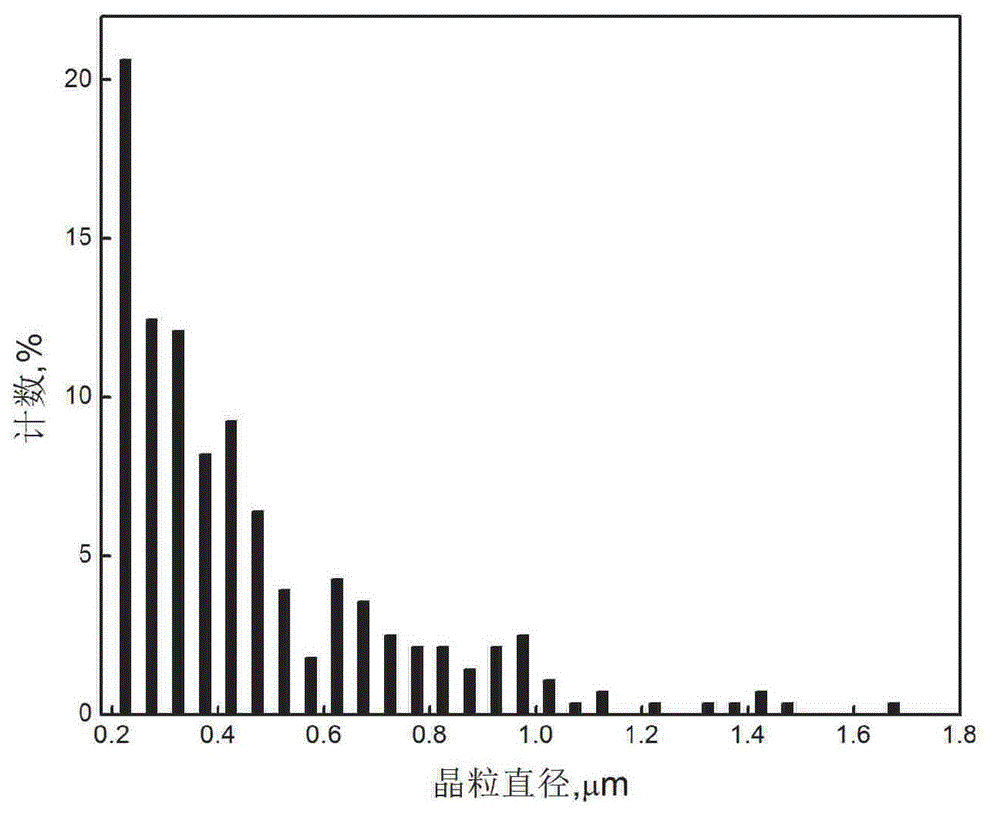

[0023] Size, Morphology and Distribution of Free Cementite Particles in SPCC Aluminum Killed Steel

[0024] 1. Sample preparation. According to the EBSD sample preparation requirements, first cut the block sample into a thin slice sample with a length of 10mm, a width of 10mm, and a thickness of 1mm to ensure that the upper and lower surfaces are parallel, then pre-grind and polish the surface, and then perform electrolytic polishing to remove the stress layer on the surface. Make sure the kikuchi pattern is clearly visible.

[0025] 2. Electron beam status. In order to obtain a fine beam spot, parameters such as accelerating voltage, probe current, and working distance need to be adjusted. The best conditions selected for this test are: accelerating voltage 15kV, probe current 2.5nA, and the diameter of the beam spot is less than 100nm at this time. The distance is 15mm, the inclination angle of the sample stage is 70°, and the 3# objective lens diaphragm is selected at the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com