Wireless monitoring module for producing workshop based on Bluetooth wireless communication

A wireless communication, production workshop technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the heavy task of communication between the controller and the monitoring terminal, the expensive CAN communication interface card, and the complicated and troublesome wiring of the electrical control cabinet. and other problems, to achieve the effect of good practicability and economy, easy test and debugging, and improved convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

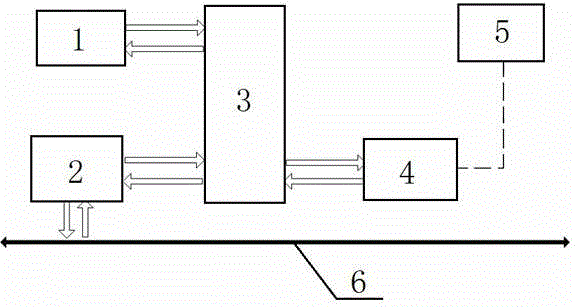

[0019] Such as figure 1 As shown, the wireless monitoring module for production workshop based on Bluetooth wireless communication of the present invention includes a monitoring terminal 6 with Bluetooth function, a Bluetooth wireless module 5 , an arithmetic processing unit 3 , and a CAN bus interface module 2 . The monitoring terminal 6 with bluetooth function is connected and communicated with the bluetooth wireless module 5 through the bluetooth 2.0 EDR mode wireless communication protocol. The Bluetooth wireless module 5 is connected with the operation control unit 3 through a serial communication connection. The operation control unit 3 is connected to the CAN bus 7 of the manufacturing workshop through the CAN bus interface 2 to exchange information and control with other control nodes. The monitoring terminal 6 with bluetooth function is any one of a smart phone, a PDA or a portable computer. The monitoring terminal 6 with bluetooth function has an expansion memory c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com