A cleaning method for high-purity gallium container

A container and high-purity technology, applied in liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems that affect the recycling of containers, cannot achieve gallium recovery, and low specificity, and achieve low cost , simple cleaning, and the effect of reducing surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

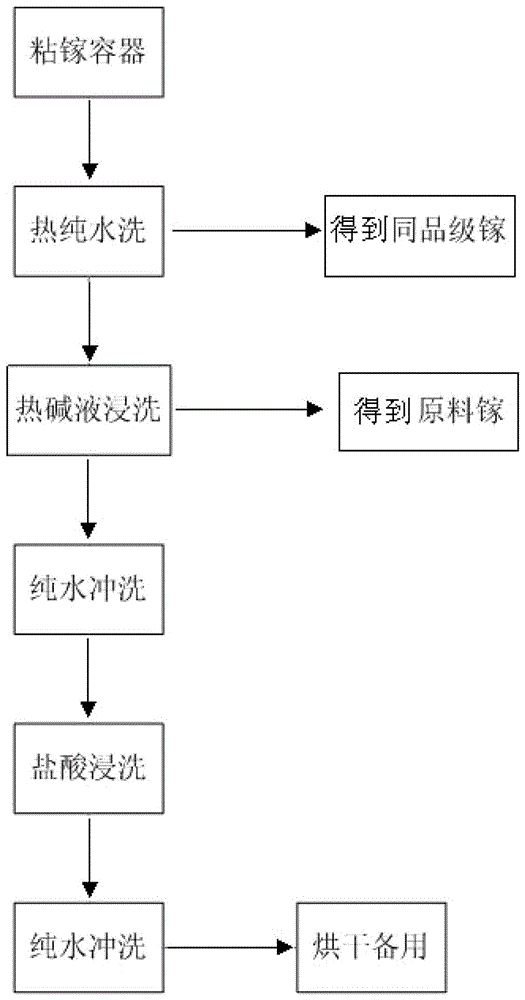

Image

Examples

Embodiment 1

[0027] To clean the container of high-purity gallium products, the steps are as follows: (1) Put the polypropylene plastic bucket with high-purity gallium products in high-purity water with a resistivity greater than 18.2MΩ·cm and heat to 80°C, soak the container for 15 minutes, and use a shaker to clean the container. Vibration makes the gallium melt into a liquid state. At this time, a small amount of liquid gallium will be detached from the container. The detached high-purity gallium can still be used as a high-purity gallium finished product after being dried; (2) use electronically pure sodium hydroxide, Prepare a 2mol / L solution, heat it to 80°C, soak the container for 10 minutes, and shake it with a shaker for 10 minutes at the same time. At this time, all the liquid gallium will automatically separate from the plastic container and gather into large droplets. Pour it out of the container and collect Liquid gallium can be used as raw material gallium; (3) Rinse the conta...

Embodiment 2

[0029] A method for cleaning a plastic beaker containing high-purity gallium intermediates, the steps are as follows: (1) use high-purity water with a resistance of 18.2MΩ·m to heat to 60°C, soak the container for 25 minutes, shake the shaker, so that the gallium melts into a liquid state, and the detached After the high-purity gallium is dried, it can be returned to the same production process as the original high-purity gallium intermediate product; (2) Prepare a 1mol / L solution with electronically pure potassium hydroxide, heat it to 80°C, and soak the container 10 minutes, shake it with a shaker for 10 minutes at the same time, all the gallium will be separated from the plastic container automatically, gather into large liquid droplets, and all will be poured out of the container smoothly, and the liquid gallium collected at this time can be used as raw material gallium; Rinse the container without gallium adhesion with high-purity water with a rate of 18.2MΩ·cm; (4) prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com