Kitchen waste processing apparatus

A technology of kitchen waste and treatment equipment, which is applied in the field of kitchen waste treatment equipment, can solve problems such as inability to use waste heat, wrong operation, and leakage of by-products, and achieve the effects of promoting drying and decomposition, preventing odor, and realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

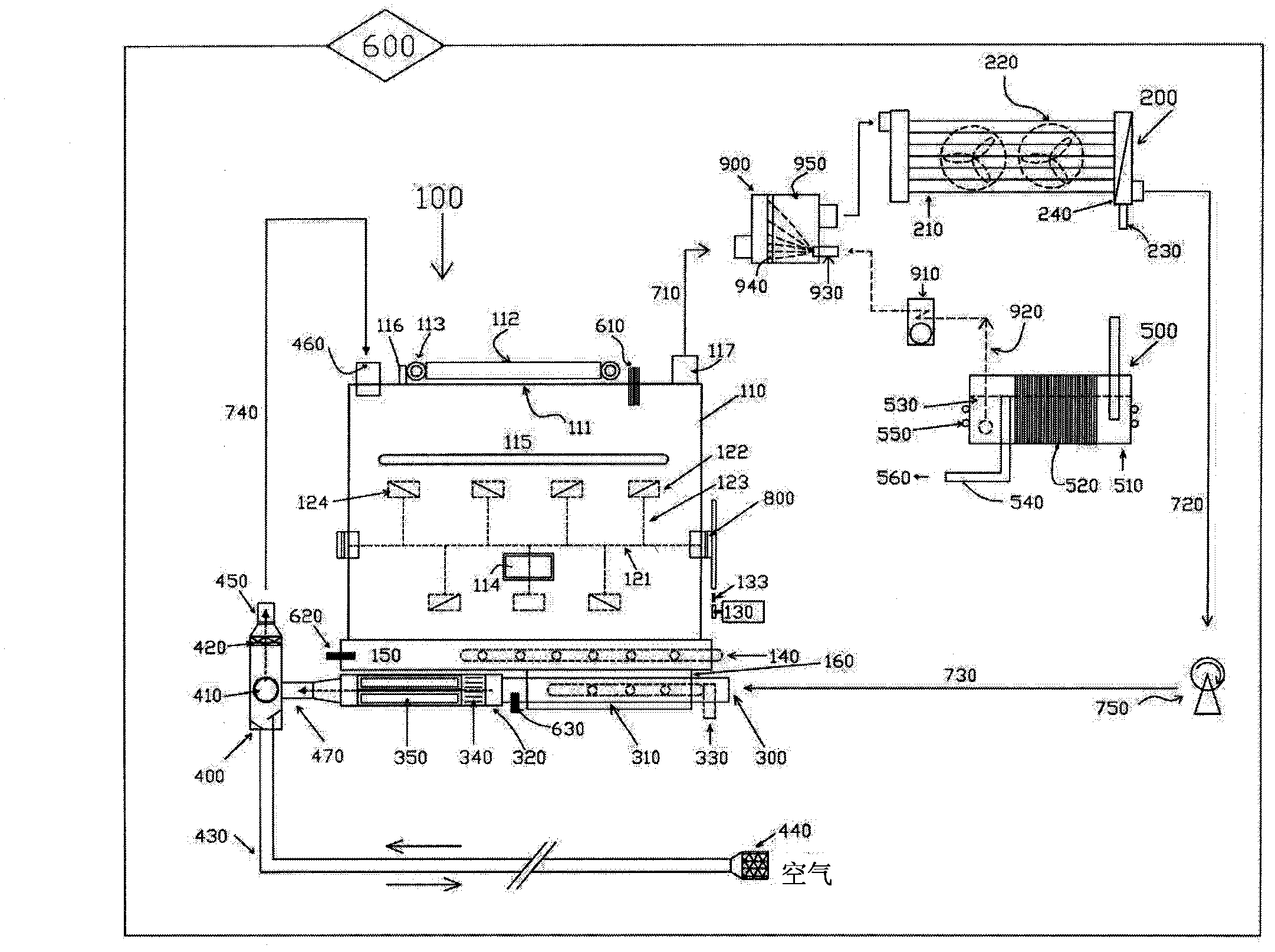

[0032] Such as figure 1 As shown, the kitchen waste treatment device provided by the present invention is generally composed of a reaction tank 100 with a heating box 160 and a driver 130, an automatic filter device 900, a condenser 200, a condensed water purification device 500, a blower 750, and a deodorization device 300 , an air circulation regulating device 400 and a controller 600 that controls the operation of the entire system.

[0033] The present invention will be described in detail below with reference to the accompanying drawings.

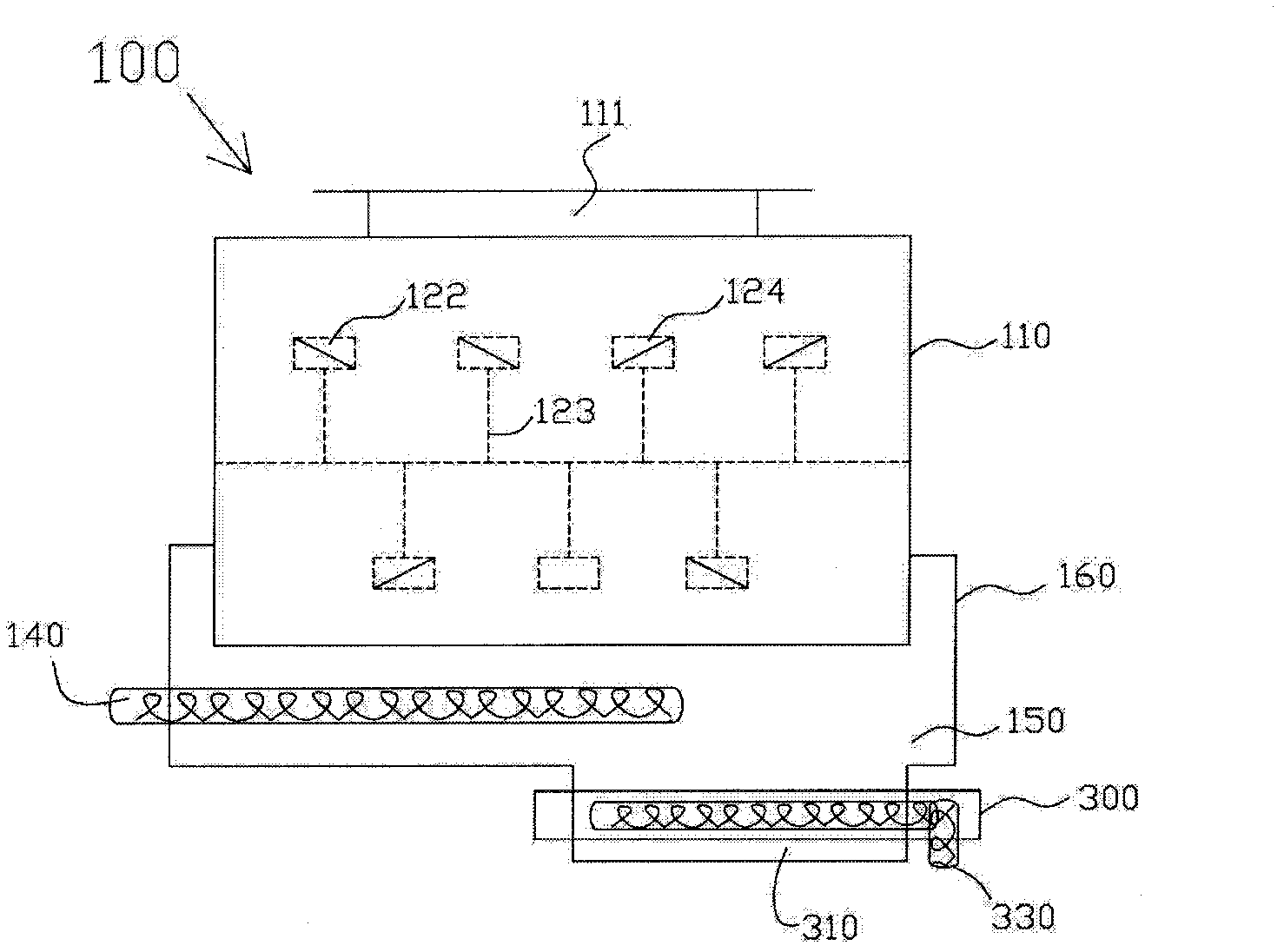

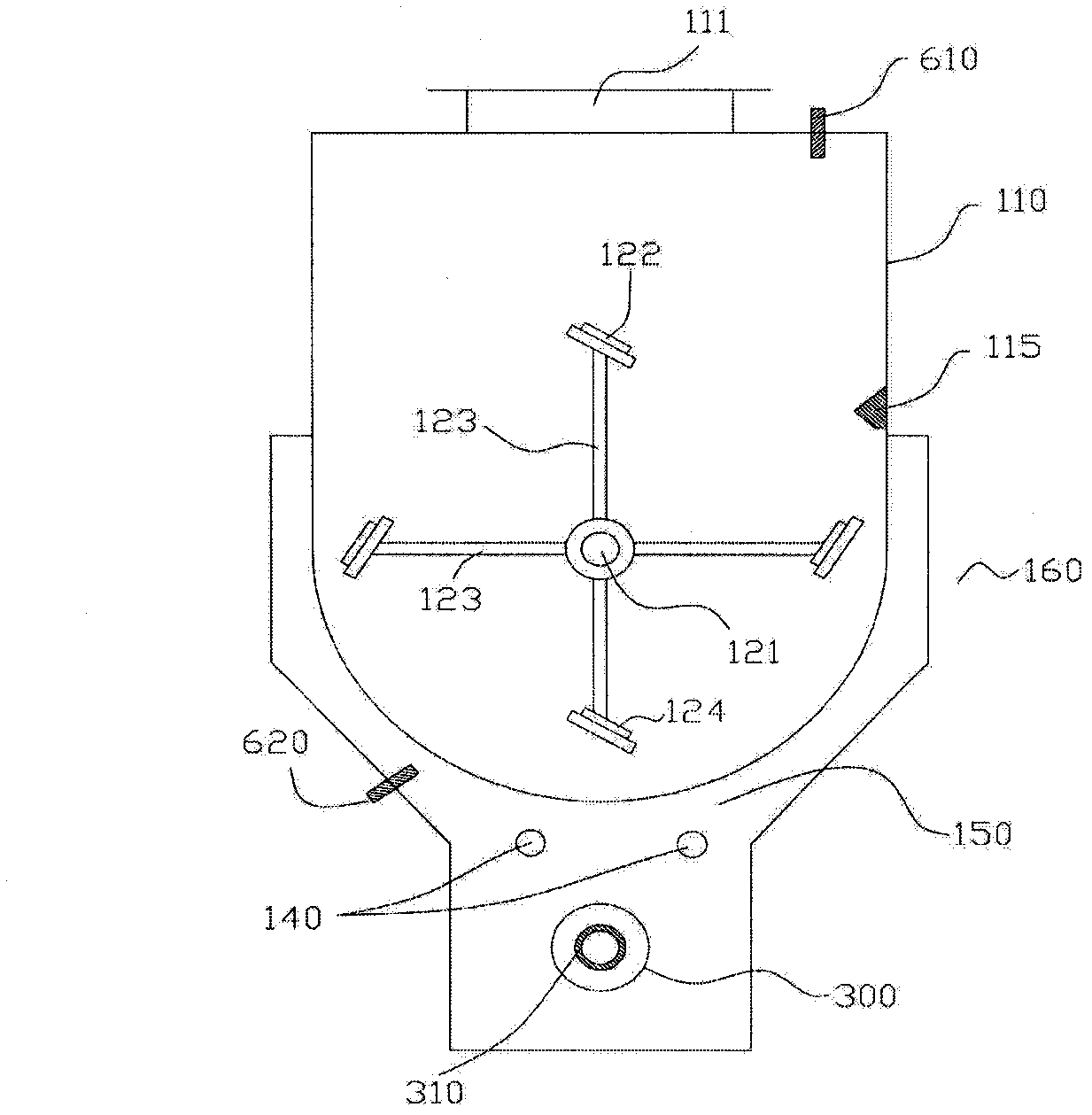

[0034] Such as Figure 2a with 2b As shown, the reaction tank 100 is composed of a feed port 111 for putting kitchen waste into the hopper 110, a hopper 110 for adorning kitchen waste, a stirring impeller 120 for stirring the kitchen waste put into the hopper 110, and a full-fill for heating. The heating tank 160 for the heat carrier oil 150 of the kitchen waste in the hopper 110, a plurality of heaters 140 for heating the heat carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com