High-speed welding device for double-TIG (tungsten inert gas) welding gun thin-wall steel pipe

A thin-walled steel pipe and welding device technology, applied in welding equipment, electrode support device, welding rod characteristics, etc., can solve the problems of complex process and many parameters, and achieve the effects of low cost, rapid and accurate adjustment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] It will be further described below in conjunction with specific implementations.

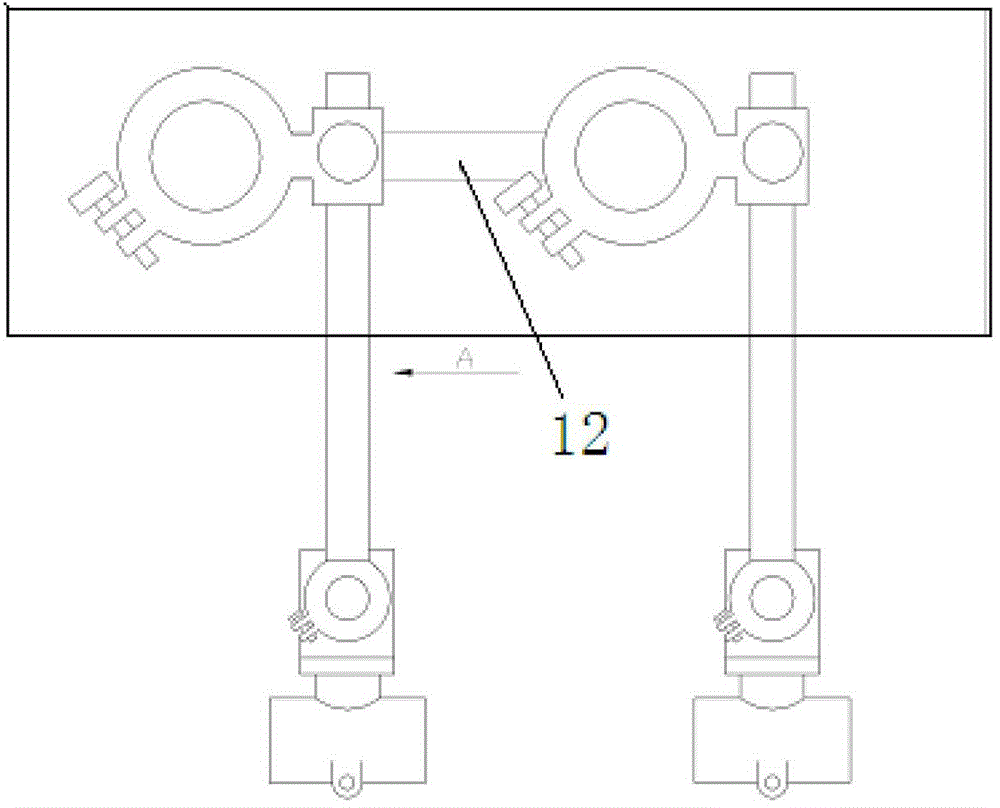

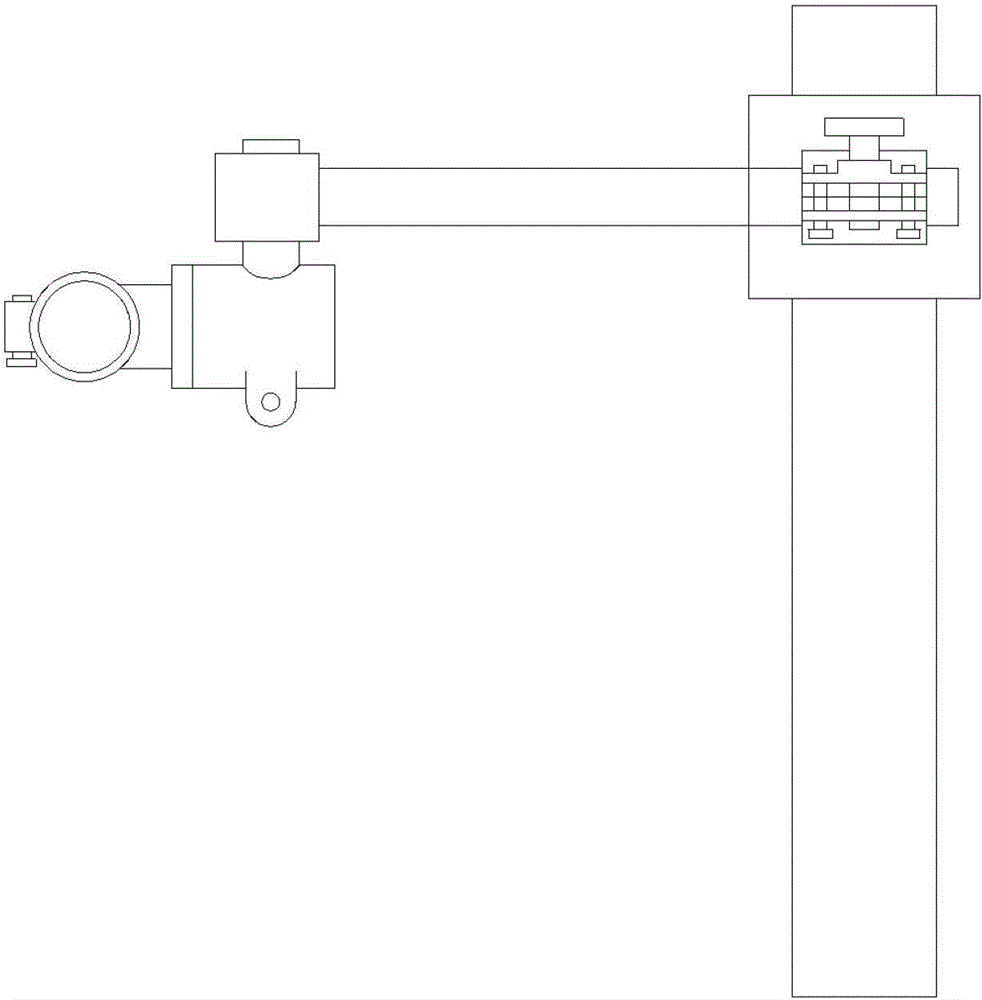

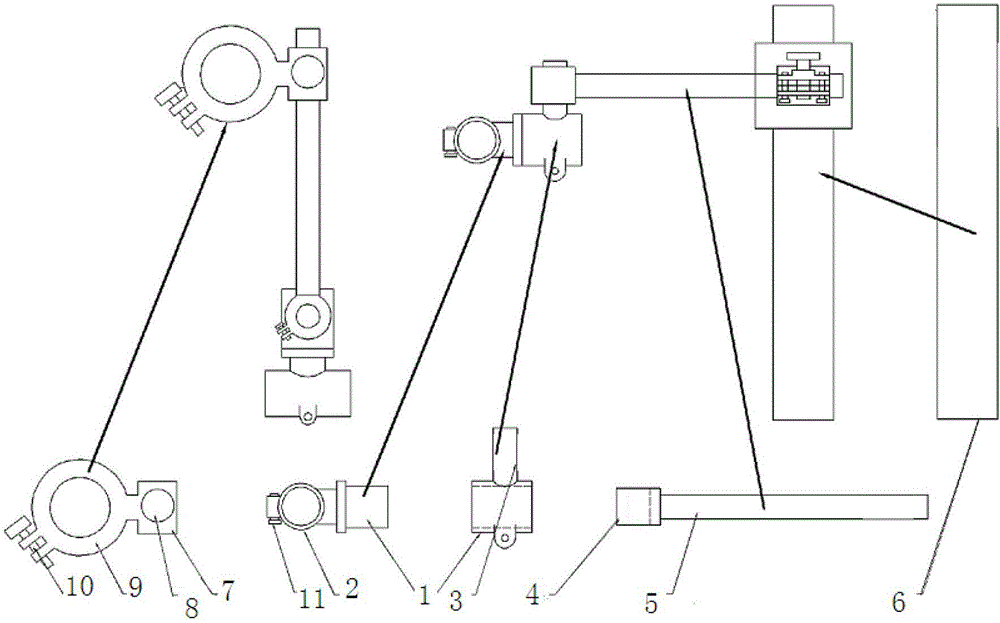

[0017] A high-speed welding device for thin-walled steel pipes with double TIG welding guns. It includes two independent welding gun adjustment mechanisms. Each welding gun adjustment mechanism includes a rotatable sleeve 1. The rotatable sleeve 1 is formed by sleeved between two barrel sections. One end of the tube section is provided with a welding gun sleeve clamp 2, and the other tube section is provided with a vertical shaft 3 and a sleeve of the transverse transmission rack 5 for rotatable socket connection. The relative rotation of the two tube sections realizes that the welding torch is perpendicular to the welding In-plane rotation, the relative rotation of the vertical shaft 3 and the sleeve 4 realizes the rotation of the welding gun in a plane parallel to the welding plane. The transverse transmission rack 5 is fixed on the height and transverse bidirectional adjustment device, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com