All-in-one machine system for loosening and tightening maintenances of railroad sleeper bolts and nuts

An all-in-one machine and nut loosening technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low maintenance work efficiency, inaccurate output torque, and inconvenient operation of sleeper bolts and nuts, so as to shorten the maintenance work. time, precise control and monitoring, the effect of lightening the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

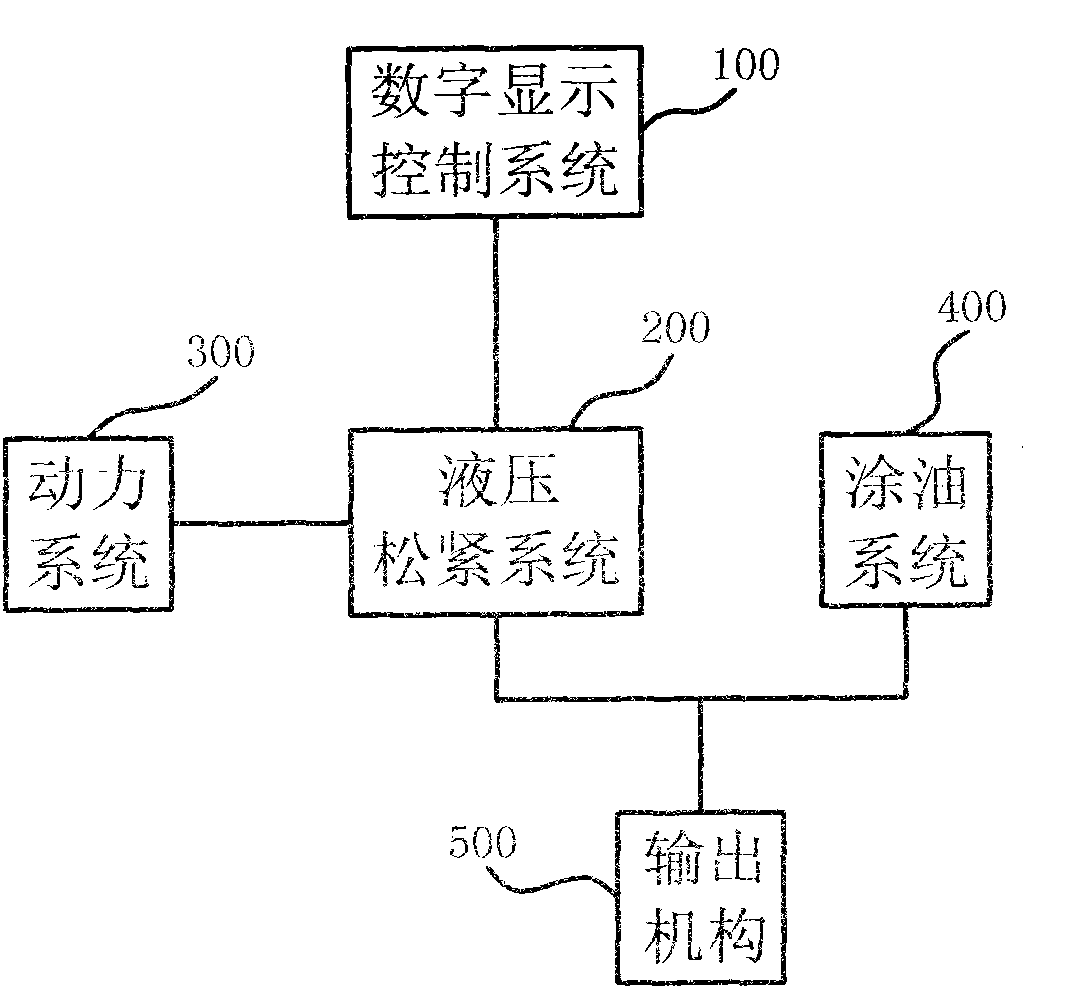

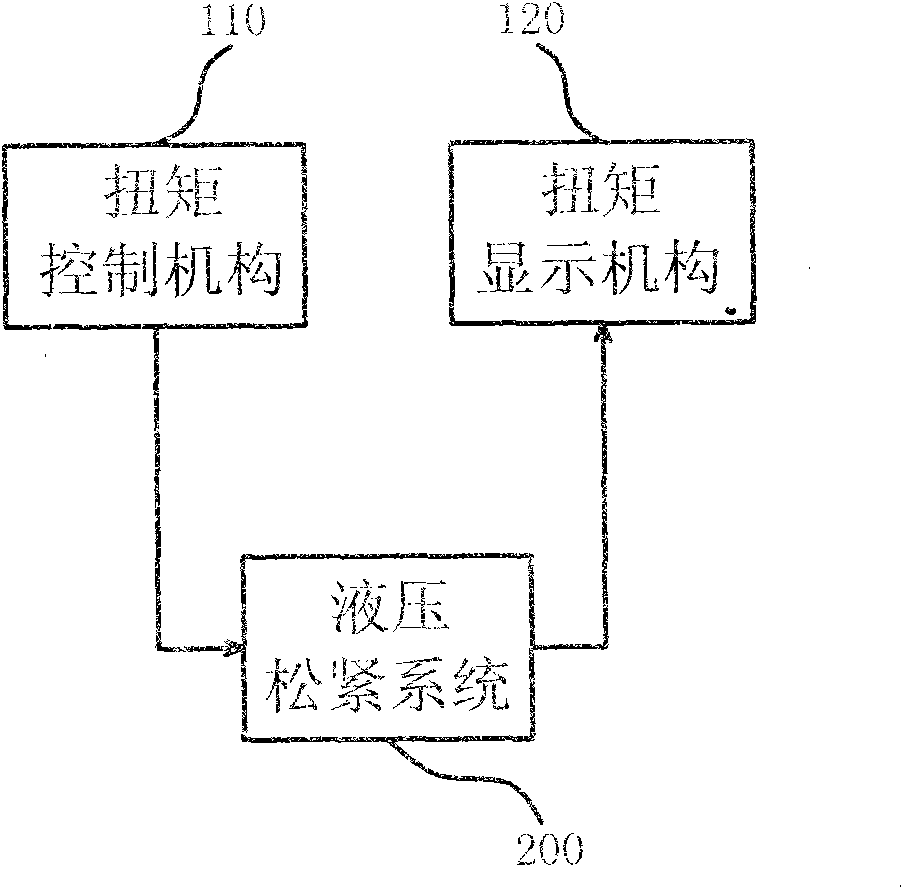

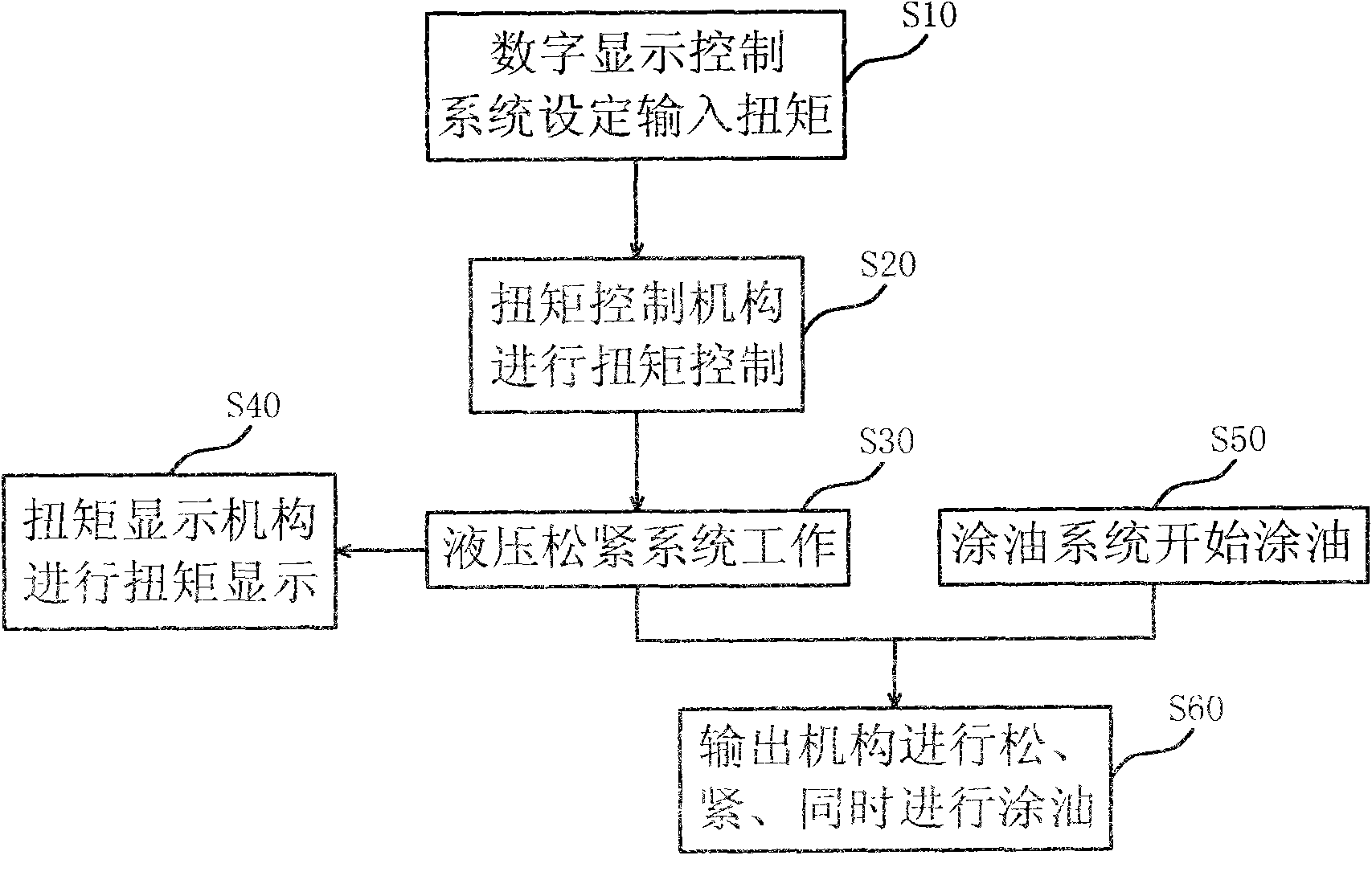

[0015] Such as figure 1 , 2 As shown, the all-in-one machine system for railway sleeper bolt and nut tightening and maintenance includes a digital display control system 100, a power system 300, a hydraulic tightening system 200, an output mechanism 500, and an oiling system 400. The digital display control system 100 includes a torque control mechanism 100 and a torque control mechanism 100. Display mechanism 120, during construction, move the all-in-one machine to the area to be constructed, make the output mechanism above the bolts and nuts, start the system, input the torque preset value through the torque control mechanism 110 of the digital display control system 100, and turn the output mechanism 500 times Press until it engages with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com