Disk type water cooling self-excited eddy current retarder

An eddy current retarder, self-excited technology, applied in cooling brakes, asynchronous inductive clutches/brakes, motors, etc., to enhance braking safety, improve braking efficiency, and avoid thermal recession

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

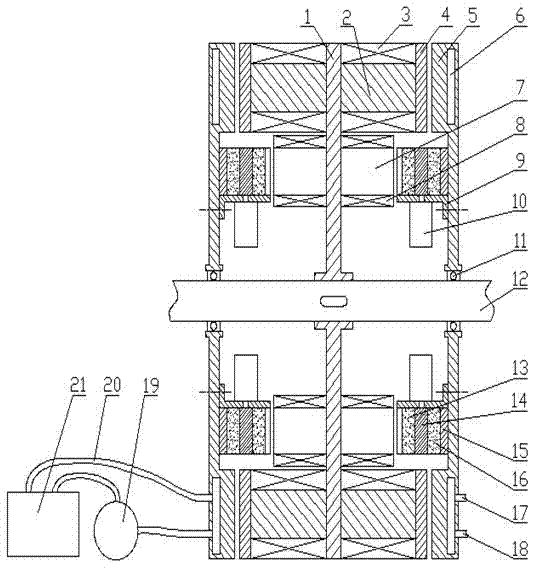

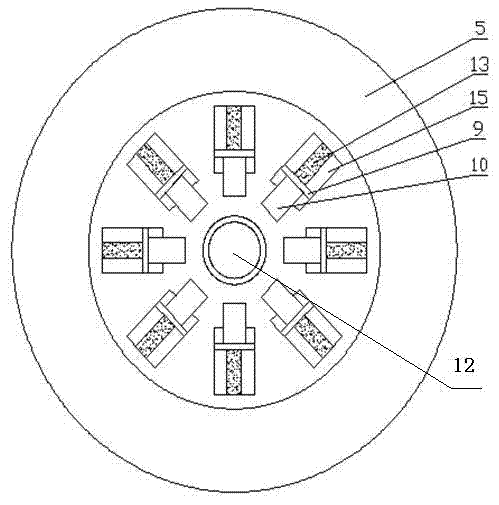

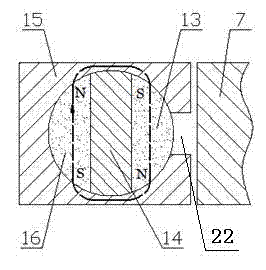

[0013] The specific implementation will be described below in conjunction with the accompanying drawings. Such as figure 1 As shown, the disc-type water-cooled self-excited eddy current retarder involved in the present invention includes four parts: a stator assembly, a rotor assembly, a transmission shaft and a cooling water circulation device. The stator assembly is made up of two stator disks 5 and permanent magnetic field generators, and the permanent magnet generators are composed of several permanent magnet generators, each of which consists of a permanent magnet generator bracket 9, a motor 10, a first permanent magnet 13, a second permanent magnet Magnet 16, partition 14 and magnetic permeable cover 15 are formed. The rotor assembly consists of a rotor frame 1 , an iron core 2 , an excitation coil 3 , an armature 7 and an armature winding 8 . The cooling water circulation device is composed of a cooling water channel 6 , a water inlet 18 , a water outlet 17 , a water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com