Machine for automatically charging thermoplastic explosives into seismic explosive column and mining blasting explosive column

A technology of automatic charging machine and source charge, which is applied to explosives, explosives processing equipment, offensive equipment, etc., can solve the problems of low production capacity, high labor intensity, low charging accuracy, etc., and achieves increased production capacity, reliable automatic control, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

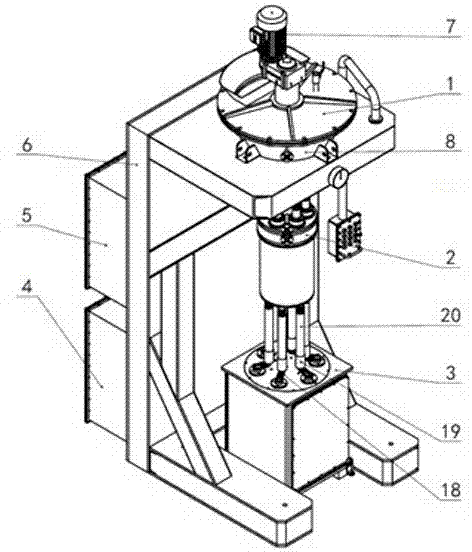

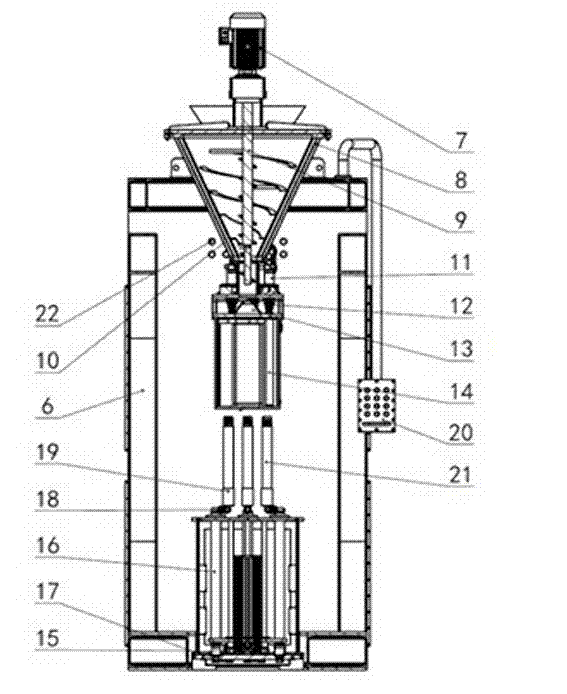

[0009] like figure 1 , 2 As shown, the present invention is composed of a material mixing system 1, a material distribution conveying system 2, a charge system 3, a PC controller 4, a hydraulic system 5 and a charge machine frame 6, and the material mixing system 1 is composed of an explosion-proof motor 7, heat preservation and mixing The pot 8, the screw propeller shaft 9 and the temperature measuring system 10 are composed, the material distribution conveying system 2 is composed of a hydraulic motor 11, a small screw shaft 12, a material distribution box 13 and a lower heat preservation mechanism 14, and the charging system 3 is composed of a servo motor 15. Lead screw 16, synchronous belt mechanism 17, torque sensor 18 and powder column housing base 19 are composed, heat preservation mixing pot 8 is installed on the charge machine frame 6, explosion-proof motor 7 is installed on heat preservation mixing pot 8, and the spiral screw The paddle shaft 9 is installed in the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com