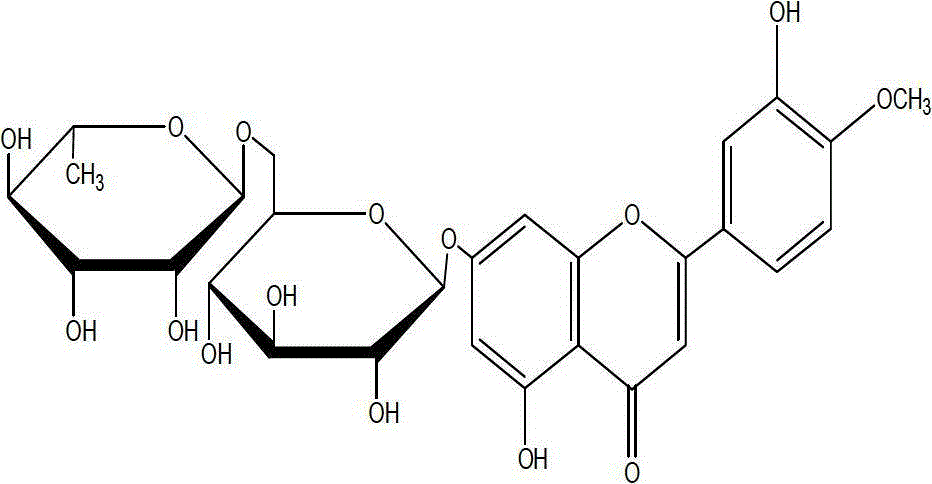

Synthesis method of diosmin

A synthetic method, the technology of diosmin, which is applied in the field of synthesis of pharmaceutical compounds, can solve the problems of low safety and high solvent residue in products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

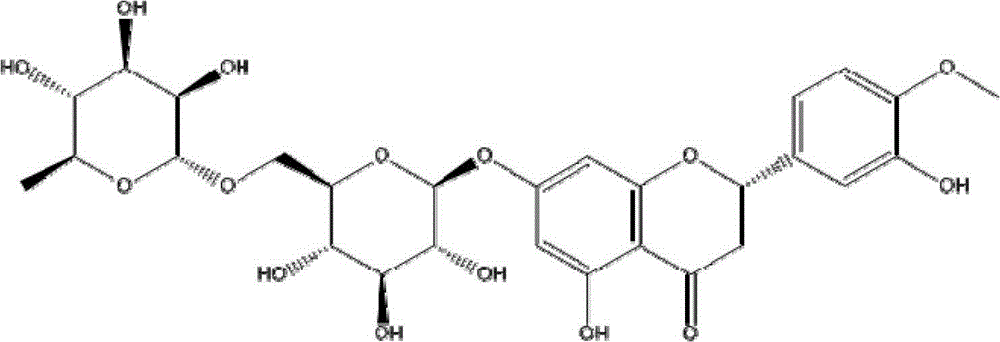

Method used

Image

Examples

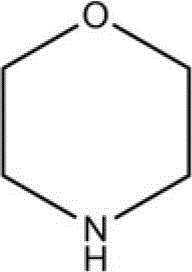

Embodiment 1

[0067] Add 100 grams of hesperidin, 47 grams of iodine, 12 grams of sodium hydroxide, and 0.8 liters of mixed solvent of morpholine:methanol (90:10) into a 1000L reaction kettle, stir until dissolved, and heat to 85-90°C for reaction 9 hours. The reaction liquid becomes a viscous liquid. After adding 3 grams of sodium thiosulfate, recover the morpholine to 70-80% under vacuum at 85-90°C. After the recovery of morpholine is completed, add 0.8 liters of water and stir evenly. Filter , collect the waste liquid, wash it with water, and get the crude product of diosmin. Add 0.8 liters of water and 30 grams of sodium hydroxide to the crude product of diosmin. After stirring and dissolving completely, filter it with a high-speed centrifuge. Put it into a crystallization tank, add water to the filtrate to 1.5 liters, Slowly add sulfuric acid to acidify until the pH is 2-3. Let stand, filter, and wash with water to obtain coarse crystals of diosmin. Add 0.8 liters of water and 30 gram...

Embodiment 2

[0069] Add 100 grams of hesperidin, 47 grams of iodine and 12 grams of sodium hydroxide in a 1000L reaction kettle, and finally add 0.8 liters of mixed solvent of morpholine: methanol (60:40), stir until completely dissolved. Heat to 85-90 ℃. Insulated and stirred for 9 hours. The reaction liquid became a viscous liquid. After adding 3 grams of sodium thiosulfate, the morpholine was recovered to 70-80% under vacuum conditions at 85-90 ° C. After the morpholine recovery was completed, add 0.8 liters of water, stir evenly, filter, collect waste liquid, wash with water, get crude diosmin, add 0.8 liters of water and 30 grams of sodium hydroxide to crude diosmin, stir and dissolve completely, filter with high-speed centrifuge, put into crystallization tank , add water to the filtrate to 1.5 liters, slowly add sulfuric acid to acidify to pH 2-3, let stand, filter, wash with water to obtain crude crystals of diosmin. Add 0.8 liters of water and 30 grams of sodium hydroxide to the cr...

Embodiment 3

[0071] Add 100 grams of hesperidin, 47 grams of iodine and 12 grams of sodium hydroxide in a 1000L reaction kettle, and finally add 0.8 liters of mixed solvent of morpholine: ethanol (90:10), stir until completely dissolved. Heat to 85-90 ℃. Insulated and stirred for 9 hours. The reaction liquid became a viscous liquid. After adding 3 grams of sodium thiosulfate, the morpholine was recovered to 70-80% under vacuum conditions at 85-90 ° C. After the morpholine recovery was completed, add 0.8 liters of water, stir evenly, filter, collect waste liquid, wash with water, get crude diosmin, add 0.8 liters of water and 30 grams of sodium hydroxide to crude diosmin, stir and dissolve completely, filter with high-speed centrifuge, put into crystallization tank , add water to the filtrate to 1.5 liters, slowly add sulfuric acid to acidify to pH 2-3, let stand, filter, wash with water to obtain crude crystals of diosmin. Add 0.8 liters of water and 30 grams of sodium hydroxide to the cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com