System and method for processing condensate oil

A technology of condensate oil and bottom oil, which is applied in the field of petrochemical industry, which can solve the problems of safety and environmental impact, unsafety, unstable production, etc., and achieve the effect of reducing energy consumption and processing loss, reducing volatilization loss, and easing operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

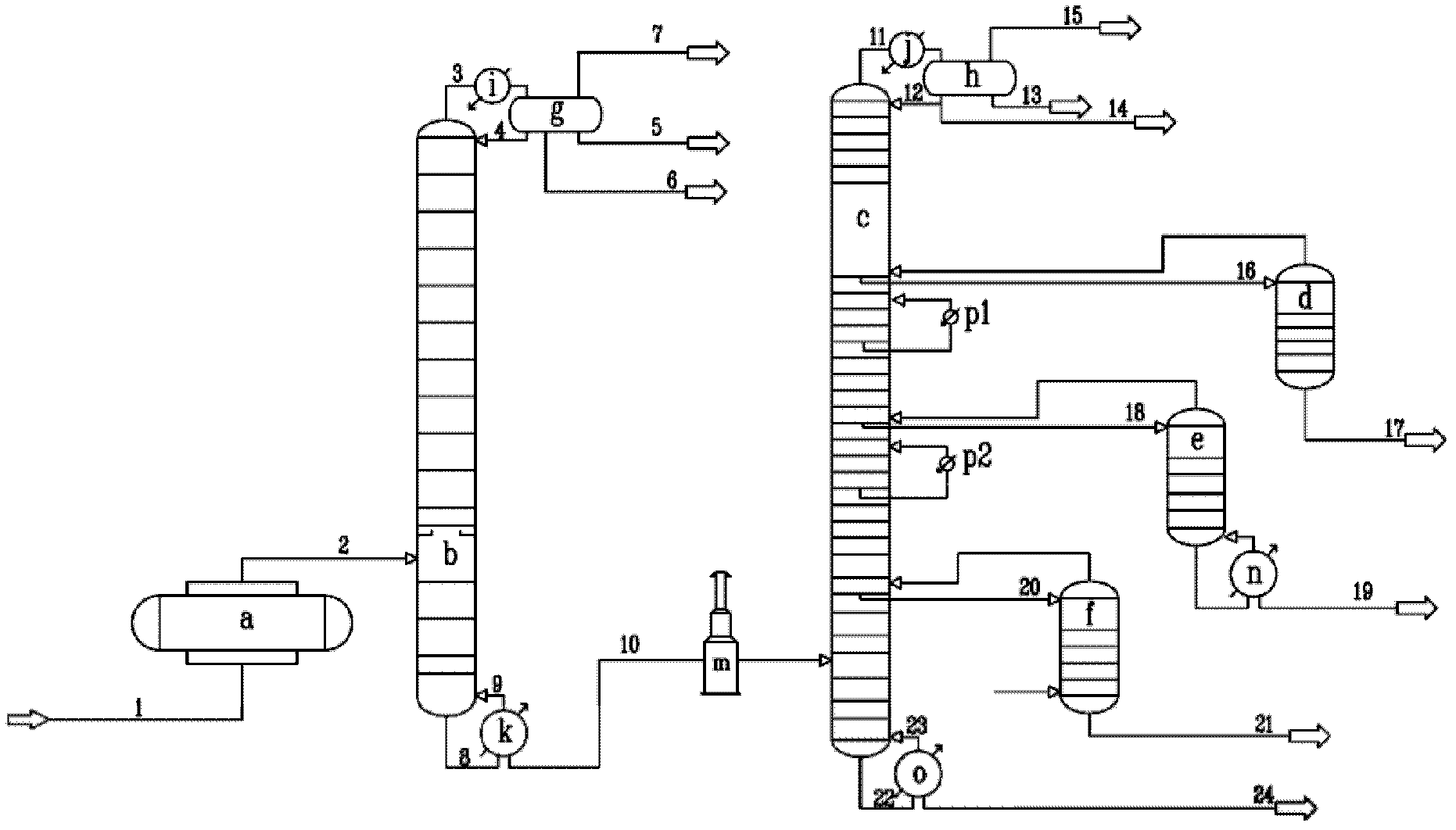

[0064] Such as figure 1 As shown, a system for processing condensate oil includes an initial distillation column b and an atmospheric column c, the outlet at the bottom of the initial distillation column b is connected to the inlet of the atmospheric column c, and condensers are respectively installed on the top of the initial distillation column and the atmospheric column i and j. The bottom of the initial distillation column b is provided with an initial distillation column reboiler k; the bottom of the atmospheric column c is provided with an atmospheric column reboiler o.

[0065] The condensate raw oil does not contain light hydrocarbon components of C3, C4 and below;

[0066] Condensate crude oil 1 comes from the device, after heat exchange, it enters the electric desalting equipment a for desalination and dehydration, and the desalted crude oil 2 is then heat exchanged to 150°C and then enters the initial distillation tower b. The initial distillation tower b adopts a...

Embodiment 2

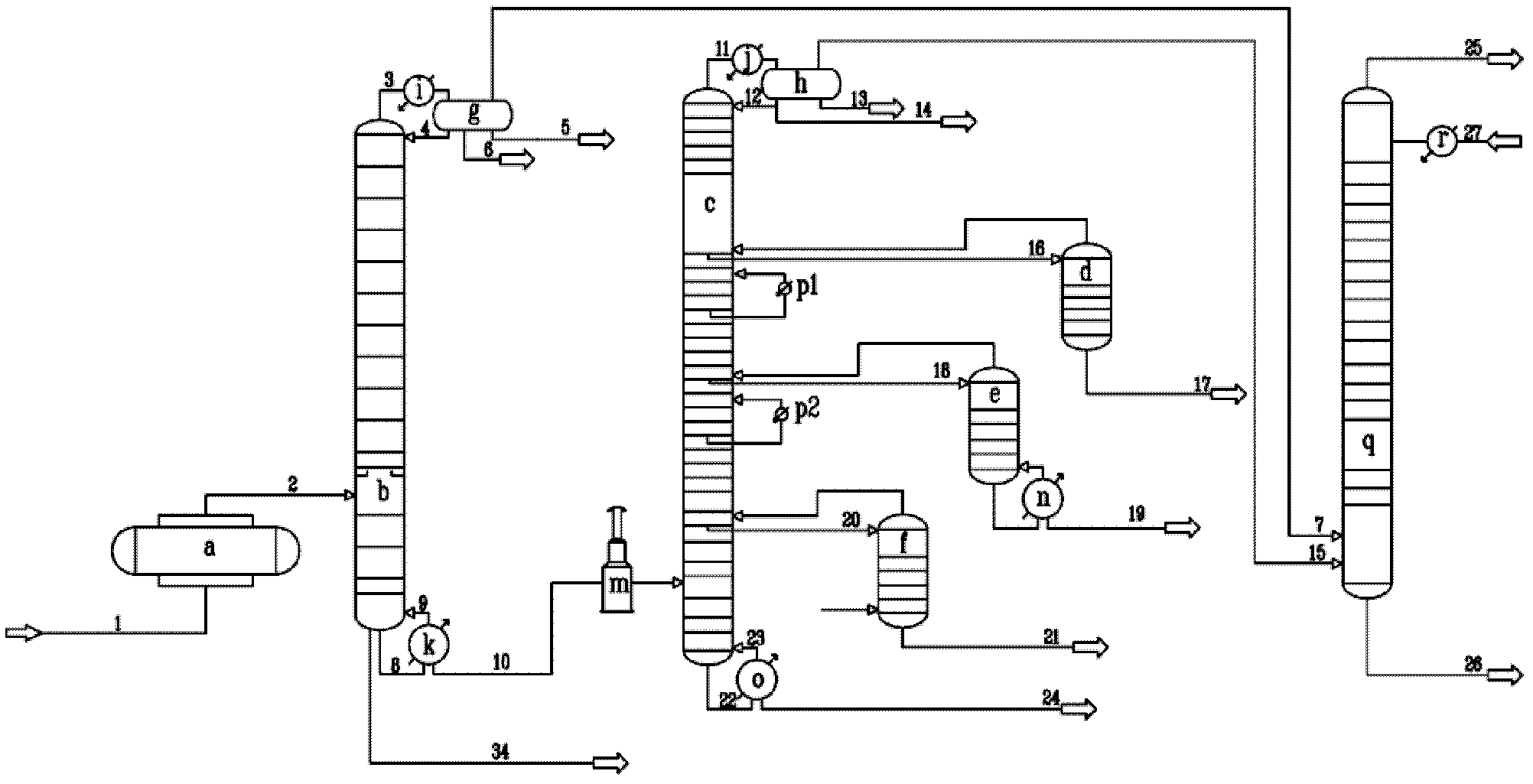

[0072] Such as figure 2 As shown, a system for processing condensate oil includes an initial distillation column b and an atmospheric column c, the outlet at the bottom of the initial distillation column b is connected to the inlet of the atmospheric column c, and condensers are respectively installed on the top of the initial distillation column and the atmospheric column i and j, the atmospheric pressure absorption tower q is set behind the atmospheric pressure tower c, and the top outlets of the initial distillation tower and the atmospheric pressure tower are connected with the atmospheric pressure absorption tower inlet. The bottom of the initial distillation column b is provided with an initial distillation column reboiler k; the bottom of the atmospheric column c is provided with an atmospheric column reboiler o.

[0073] Condensate oil contains C3, C4 components, or contains C3, C4 and below components;

[0074] Condensate crude oil 1 comes from the device, after hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com