Pre-stress construction system

A prestressed and force measuring ring technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of lack of construction engineering funds, engineering cycle, large radial effect, and increased friction coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but this is not a limitation of the present invention. The scope of protection of the present invention is subject to the contents recorded in the claims, and any equivalent technical means replacement made according to the specification will not depart from protection scope of the present invention.

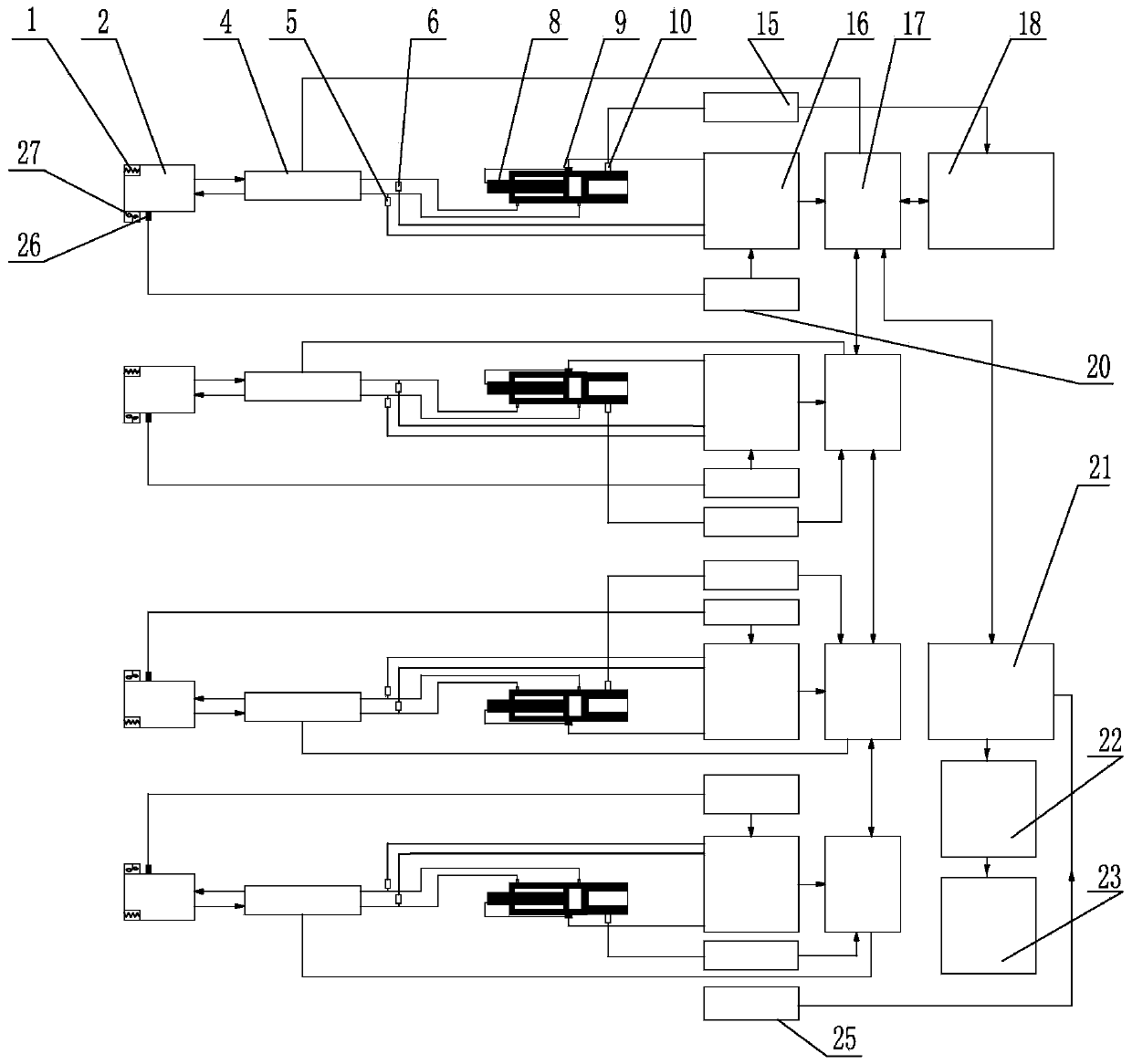

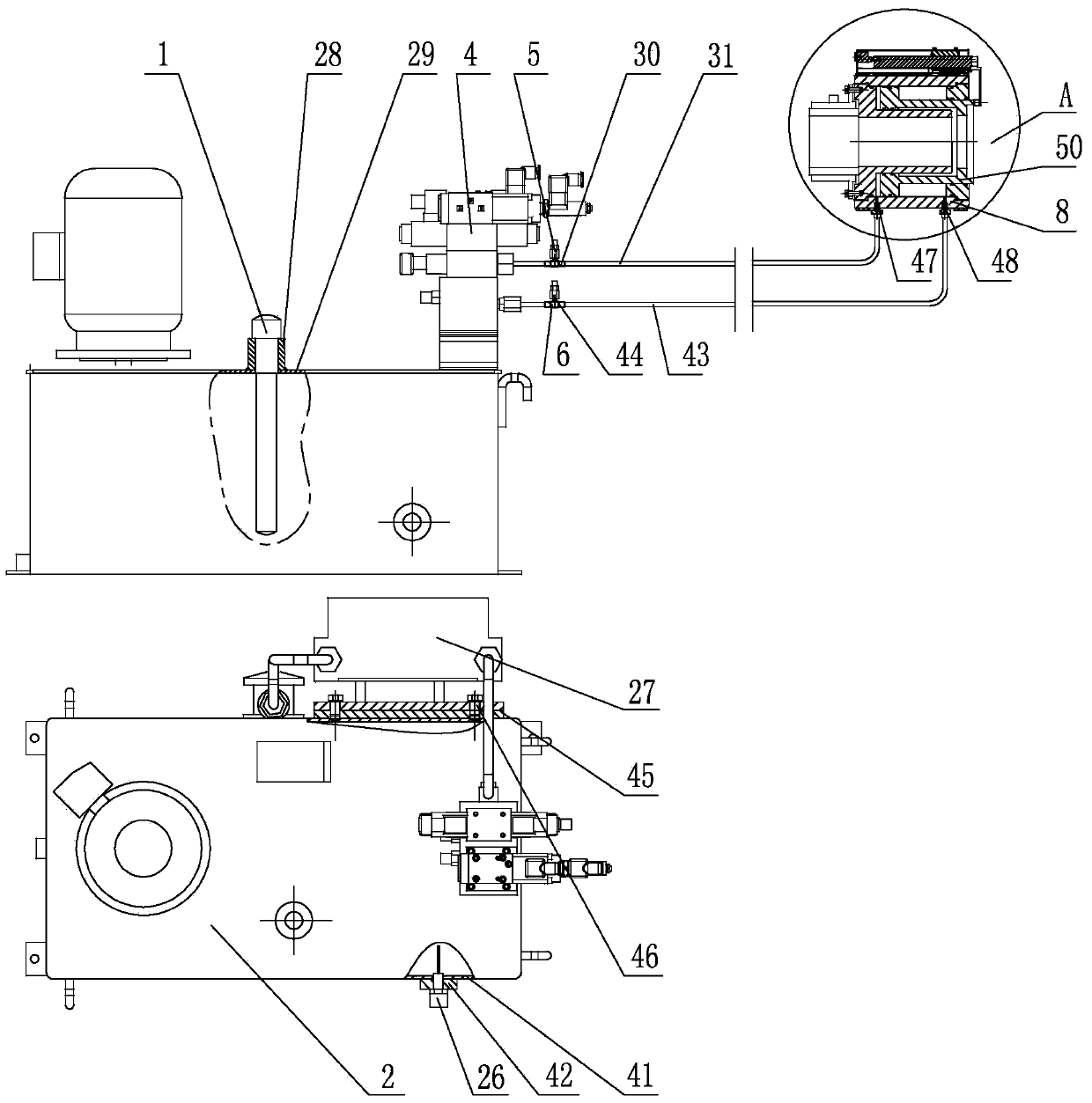

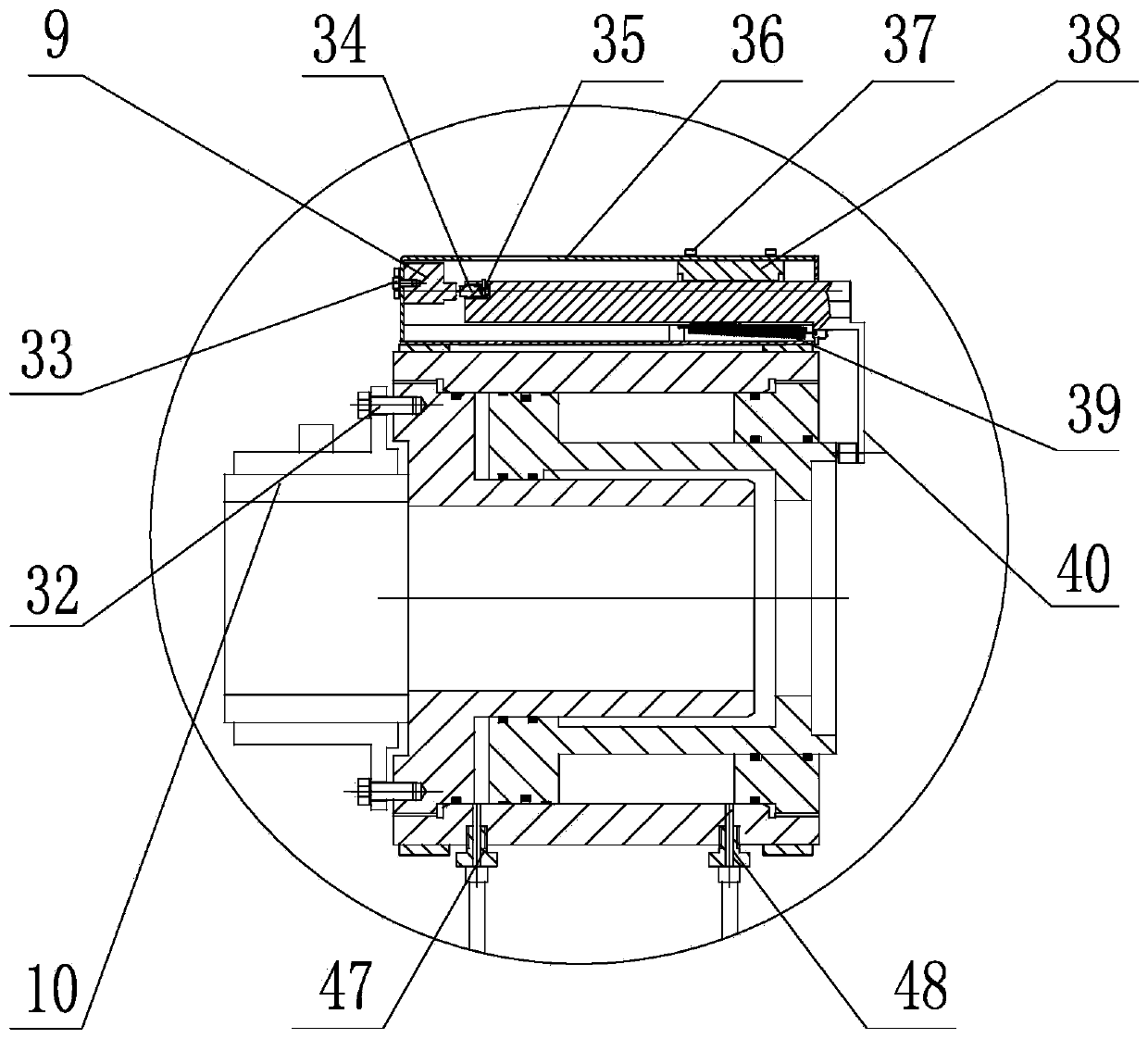

[0099] The overall technical structure of the present invention is as shown in the figure, which includes four groups of tensioning devices, each group of tensioning devices includes hydraulic station 2, reversing valve group 4, jack 8, A / D acquisition module 16, PLC controller 17, human The machine interface 18 is electrically connected to the PLC controller 17 in each group of tensioning devices. The pressure oil pumped out by the hydraulic station 2 is output to the jack 8 through the reversing valve group 4, and the pressure signal generated by the ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com