Starting system of motor type free piston internal combustion power generation device

A technology of power generation device and starting system, which is applied in the field of power machinery, can solve the problems of no crank connecting rod mechanism, etc., and achieve the effects of short starting time, reduced volume and fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

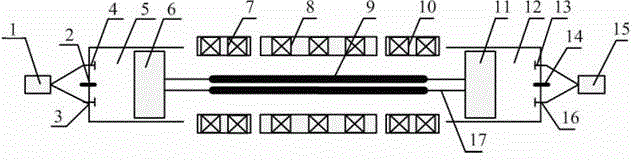

[0033] The first starting scheme: when the free piston internal combustion power generation device is not working, the piston assembly is located at the midpoint of the linear motor, the first intake valve 3, the first exhaust valve 4, the second intake valve 16 and the second exhaust valve 13 They are all in the closed state. Before starting, according to the expected compression ratio, the distance, acceleration, deceleration, and time required for the acceleration and deceleration process of the piston assembly are preset in the control program. When starting, the linear motor works in the motor mode to drive the piston assembly to move to the side of the first internal combustion engine cylinder 5 (or the second internal combustion engine cylinder 12) according to the preset setting. When the speed of the piston assembly is zero, the fuel injector of the internal combustion engine on this side The fuel is injected into the cylinder, the mixture in the cylinder is ignited an...

Embodiment 2

[0035] The second starting scheme: when the free piston internal combustion power generation device is not working, the piston assembly is located at the midpoint of the linear motor, the first intake valve 3, the first exhaust valve 4, the second intake valve 16 and the second exhaust valve 13 Both are in the closed state; when the free-piston internal combustion power generation device needs to be started, the linear motor works in the motor mode and acts on the piston assembly with a constant force, dragging the piston assembly to the first internal combustion engine cylinder 5 (or the second internal combustion engine cylinder 12) One side movement; as the gas pressure in the cylinder gradually increases, when the motor force is less than the sum of the gas pressure and friction in the cylinder, the piston assembly starts to decelerate until the speed is zero; then the motor force reverses and drags the piston The assembly moves in the opposite direction, and the piston ass...

Embodiment 3

[0037] When the free piston internal combustion power generation device is not working, the piston assembly is located at the midpoint of the linear motor, and the first intake valve 3, the first exhaust valve 4, the second intake valve 16 and the second exhaust valve 13 are all in a closed state, Before starting, according to the expected compression ratio, the distance, acceleration, deceleration, and time required for the acceleration and deceleration process of the piston assembly are preset in the control program. When starting is required, the first starting coil 7, the second starting coil 10 and the linear motor mover 9 form a starting motor, and the piston assembly is driven to the first internal combustion engine cylinder 5 (or the second internal combustion engine cylinder 12) according to the setting of the control program. One side moves, completes a process of first accelerating and then decelerating to zero, and reaches the compression ratio required for starting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com