Improved fan oil station electrical control system

An electrical control system, gas station technology, applied in general control systems, control/regulation systems, computer control, etc., can solve problems such as blind spots in monitoring, hidden dangers of interlocking functions, power loss of secondary circuit systems, etc., to avoid loops Complex maintenance is difficult, safety, stability and reliability are improved, and the effect of improving safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

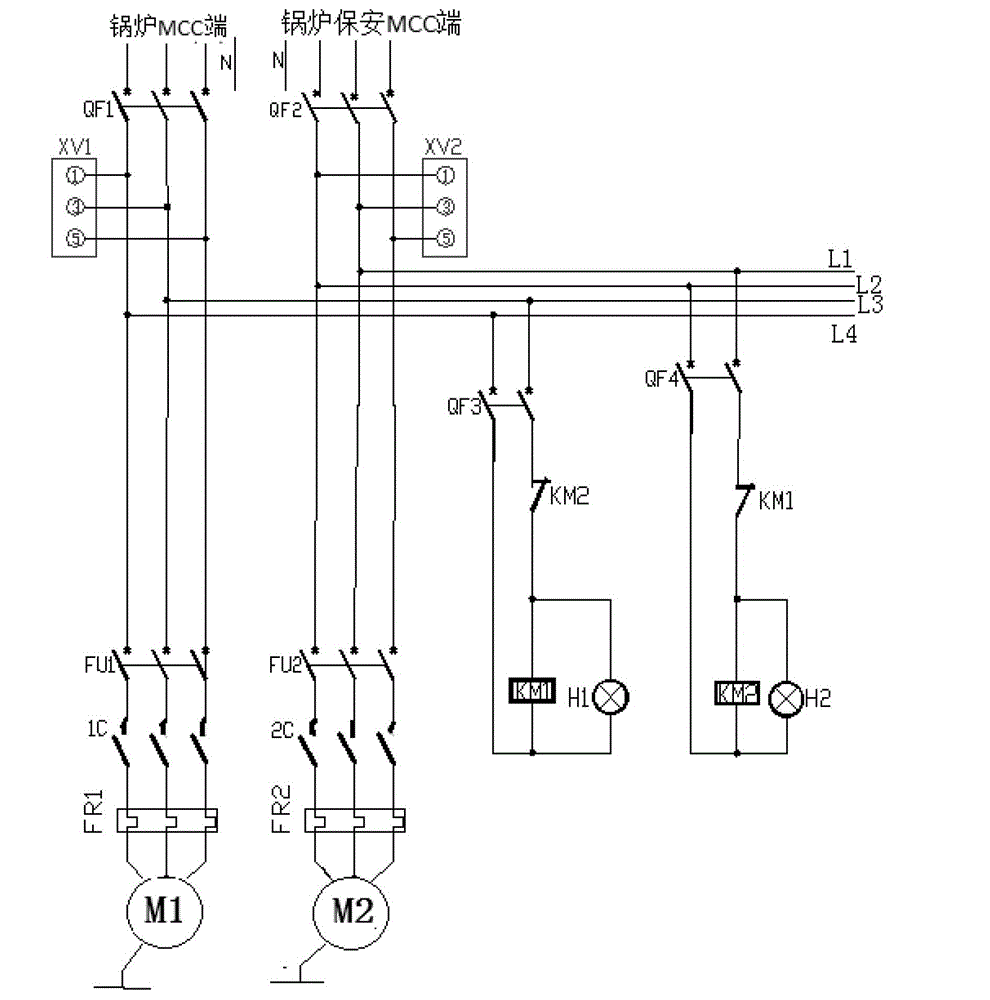

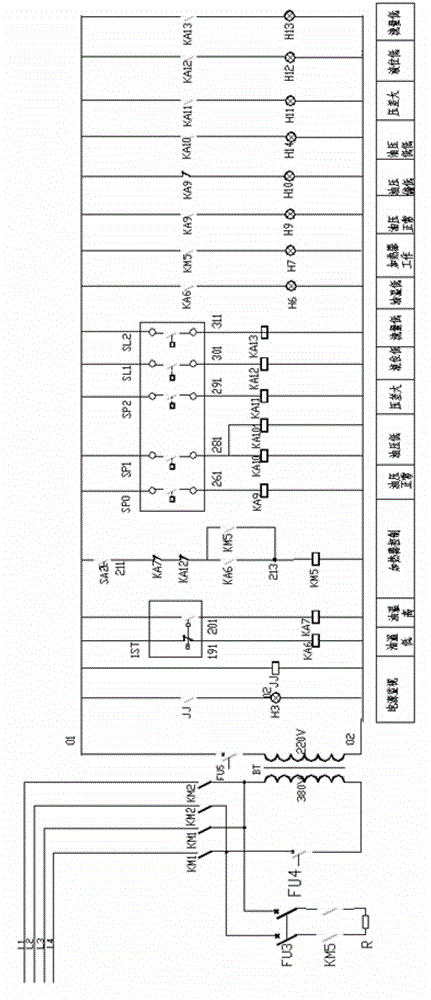

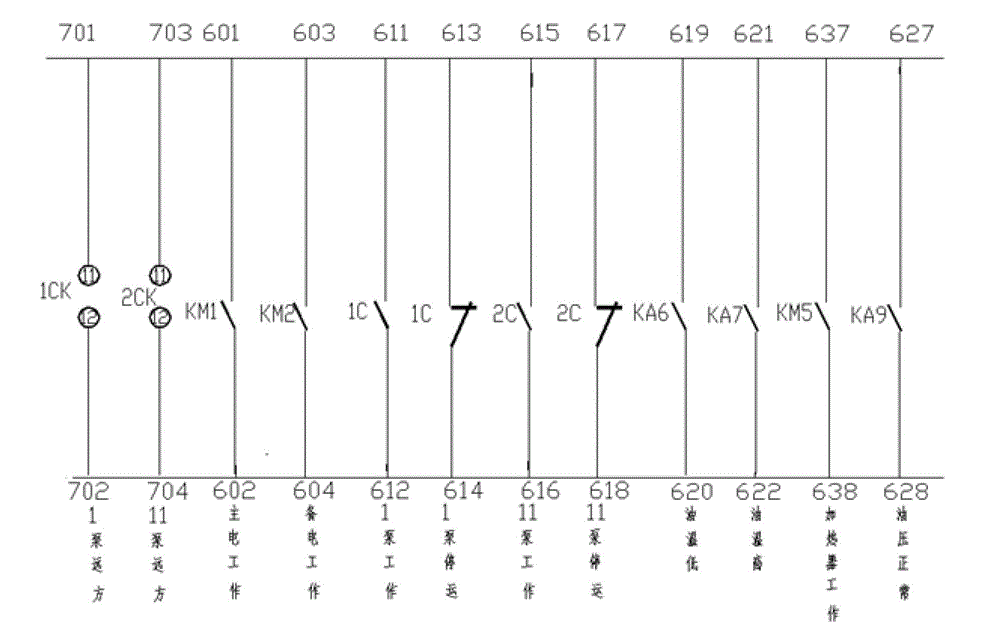

[0041] Such as figure 1 , 2 , 3, 4, 5, and 6 shown in the component circuit, the principle of electrical action and the role of important configuration components:

[0042] 1. Configure components:

[0043] 1.1QF1, QF2: Power input circuit breakers, which receive primary AC power from the upper-level MCC cabinet. QF1 is connected to the power supply of the oil station pump Ⅰ, and QF2 is connected to the power supply of the oil station pump Ⅱ;

[0044] 1.2, QF3, QF4: power input circuit breaker, it represents the power input circuit breaker of the control instrument power switching circuit.

[0045] 1.3 FU1, FU2: power output circuit breaker; FU1 is used as the power output circuit breaker of the oil station pump I, and FU2 is used as the oil station pump II power output circuit breaker. Another important function is to disconnect the FU1 and FU2 circuit breakers when the motor control circuit fails, so that the transmission inspection of the secondary circuit can be carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com