Method for manufacturing nanoscale grating based on polydimethylsiloxane (PDMS)

A manufacturing method and nano-scale technology, which are applied in diffraction grating, patterned surface photoengraving process, optics, etc., can solve the problems of harsh and complex process conditions, high manufacturing cost, difficult control, etc., and achieve simple process, low cost, Easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] A method for fabricating a nanoscale grating based on PDMS, comprising the steps of:

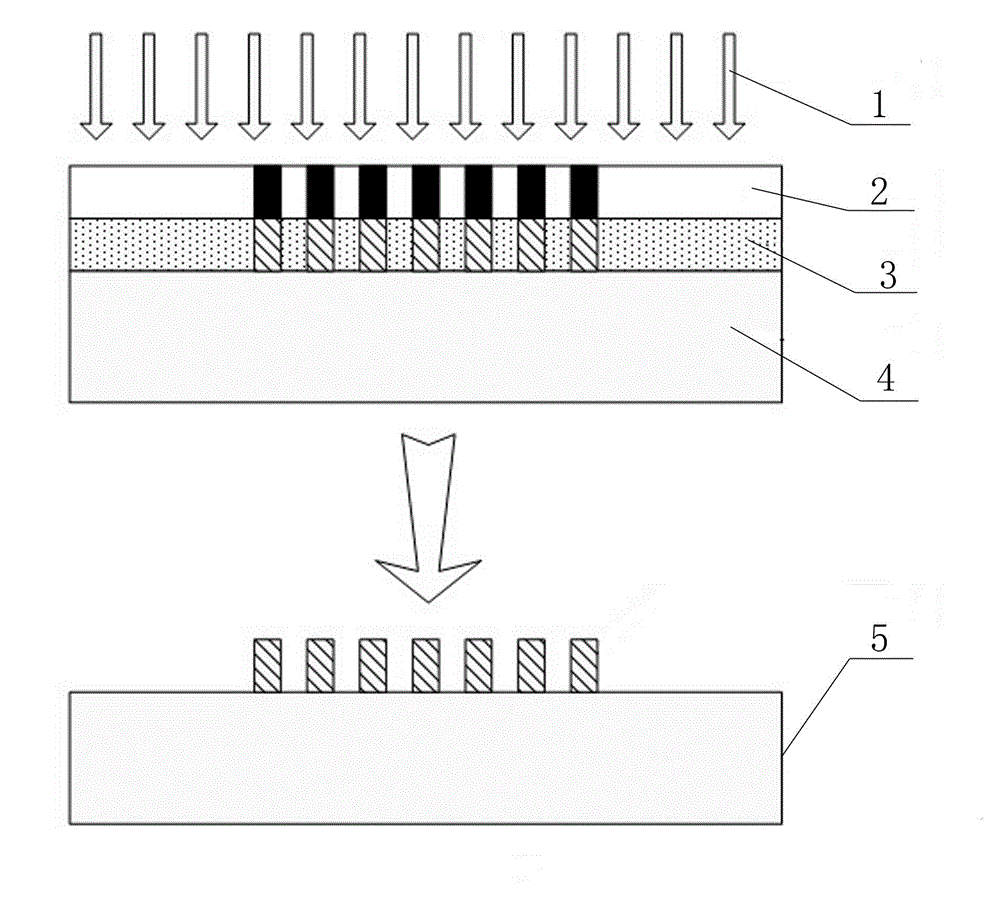

[0028] a. Make grating master template 5 by photolithography technology;

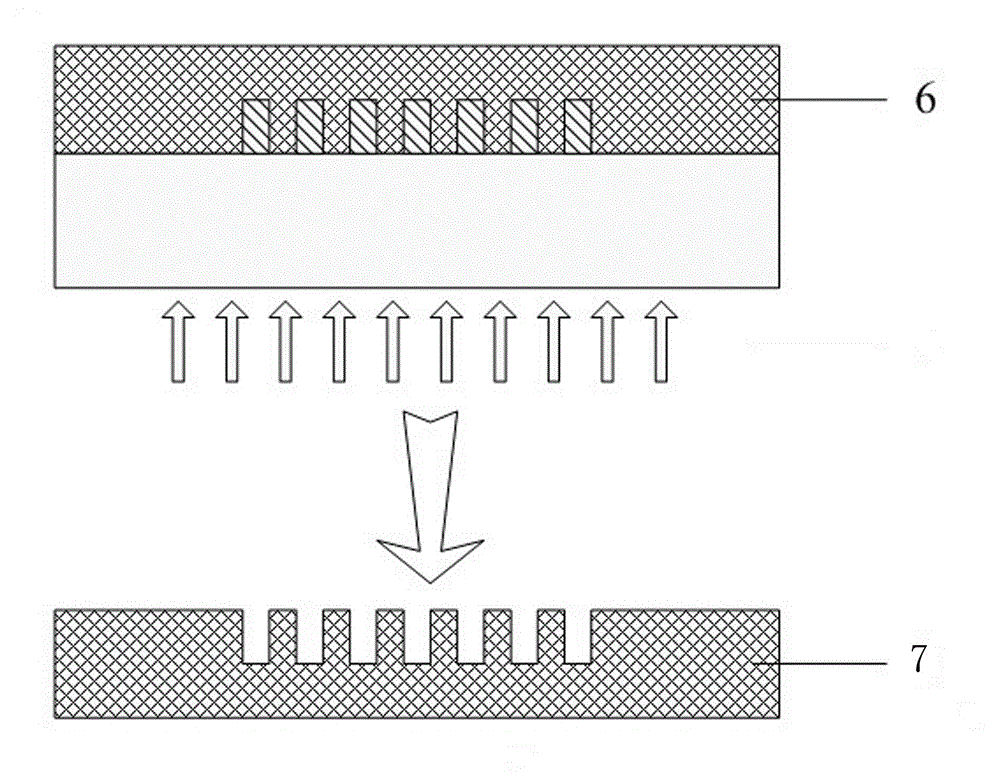

[0029] b. Transfer the grating pattern of the grating master template 5 in step a to the PDMS film 6 to make a PDMS film 7 with the grating pattern;

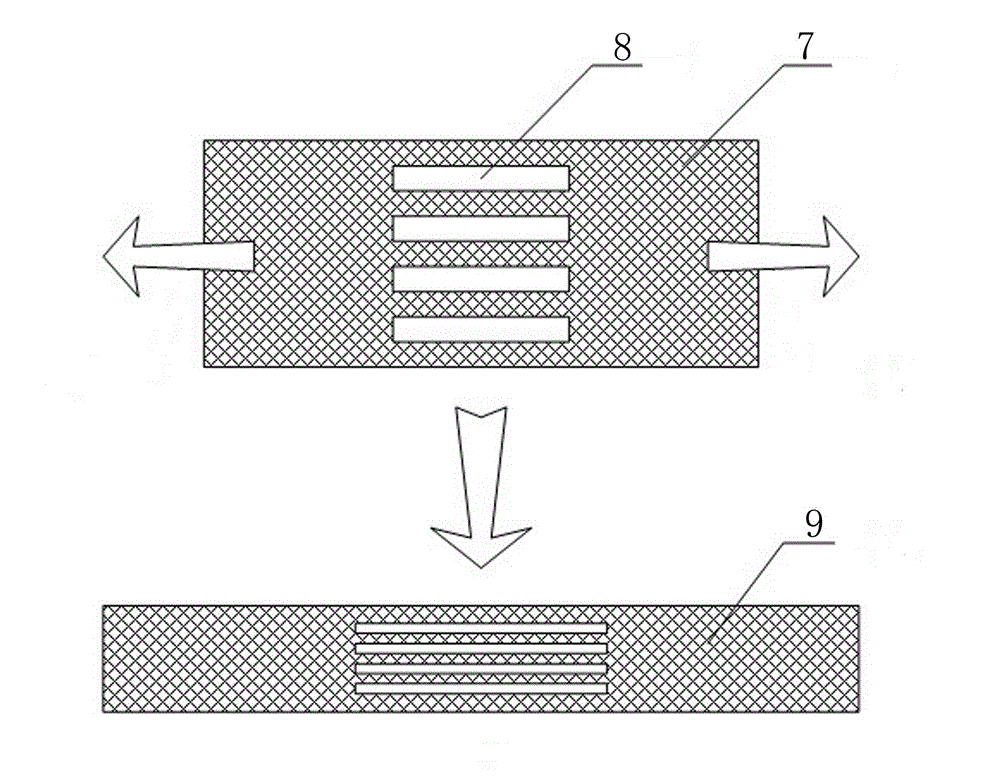

[0030] c. Clamp the PDMS film 7 with the grating pattern on the electronically controlled translation stage, after setting the stretching ratio parameter, biaxially stretch the PDMS film 7 with the grating pattern along the length direction of the grid line 8, and the grid line 8 The width of the grid line 8 is elongated and narrowed, that is, the period of the grating pattern becomes smaller, and then the stretched PDMS film 9 is fixed on a flat substrate 4;

[0031] d, transfer the grating pattern whose period becomes smaller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com