Zoom micro lens based on piezoelectric inverse effect

A technology of inverse effect and microlens, which is applied in lens, optics, instruments, etc., can solve the problems of difficult design and manufacture of array structure, large volume, slow control response speed, etc., and achieve simple design and process manufacturing, and easy realization of array structure, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

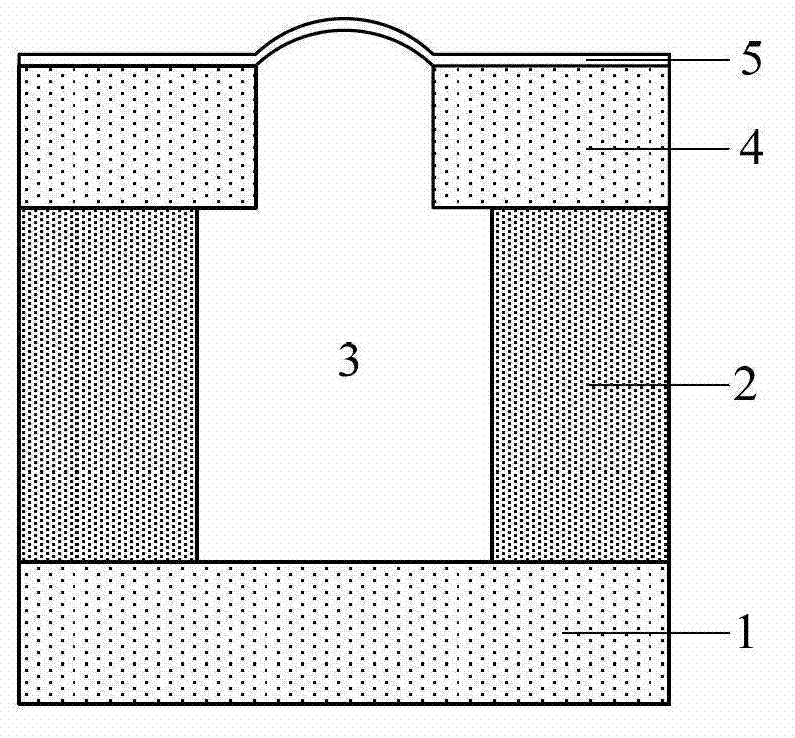

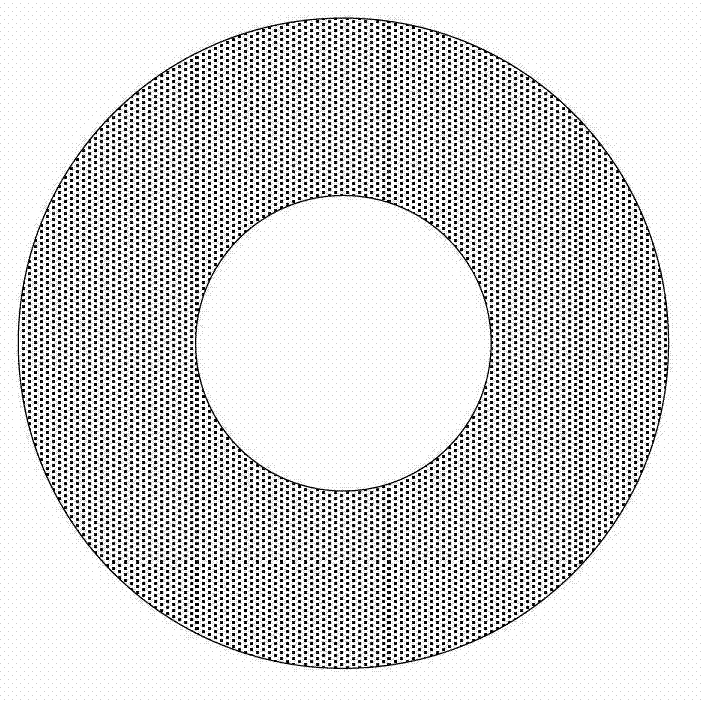

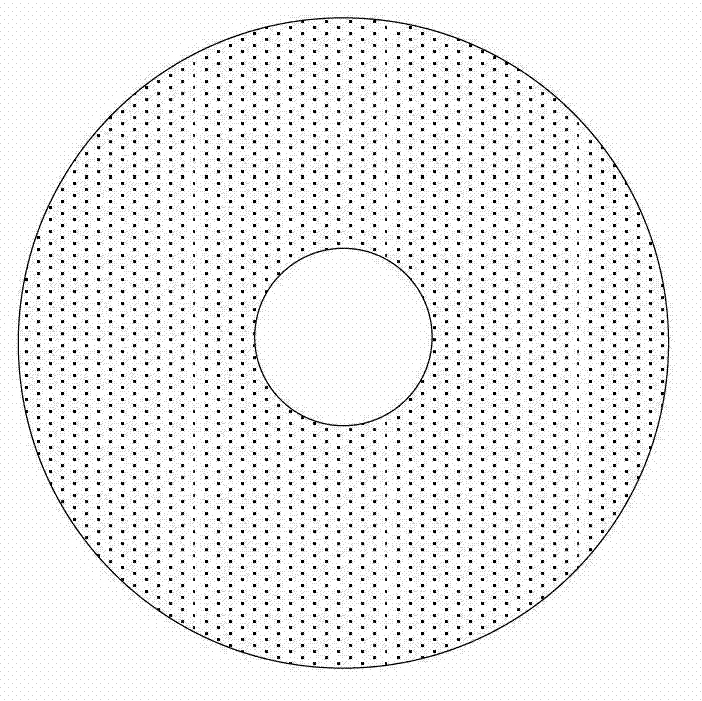

[0024] Zoom microlens based on piezoelectric inverse effect, its structure is as follows figure 1 As shown, it includes a first glass sheet 1, a piezoelectric ceramic ring 2, and a second glass sheet 4; the center of the second glass sheet 4 has a circular hole, and the surface of the second glass sheet 4 is covered with a transparent organic film 5; The piezoelectric ceramic ring 2 is clamped between the first glass sheet 1 and the second glass sheet 4, and the central circular hole of the piezoelectric ceramic ring 2 and the second glass sheet 4 remains concentric; the first glass sheet 1, the piezoelectric ceramic ring 2 and the second glass sheet 4 are sealed to form an inner space filled with a transparent liquid 3 .

[0025] For the above technical solution, the monochromatic plane wave is incident from bottom to top. When no control voltage is applied to the piezoelectric ceramic ring 2, the height of its inner cylindrical cavity is H 0 , the radius is R; when the app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com