Laser cutting path optimizing method

A path optimization and laser cutting technology, which is applied in laser welding equipment, digital control, manufacturing tools, etc., can solve the problems of reduced efficiency, slow running speed, and large amount of calculation, so as to reduce safety hazards, shorten air movement, and simple implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Such as Figure 7 As shown, it is a typical planar laser cutting drawing. There are several patterns in the graphics on this drawing. The number of these patterns is medium, and it is inconvenient to use interactive optimization; and the distribution of each pattern is relatively regular, but they are not aligned. The cutting of patterns The starting points are also different, and each pattern is also composed of several shaped outline patterns, which may be composed of closed lines or unclosed lines. After inputting the drawing into the laser cutting machine, the CAM software in the control system of the laser cutting machine performs the following processing steps:

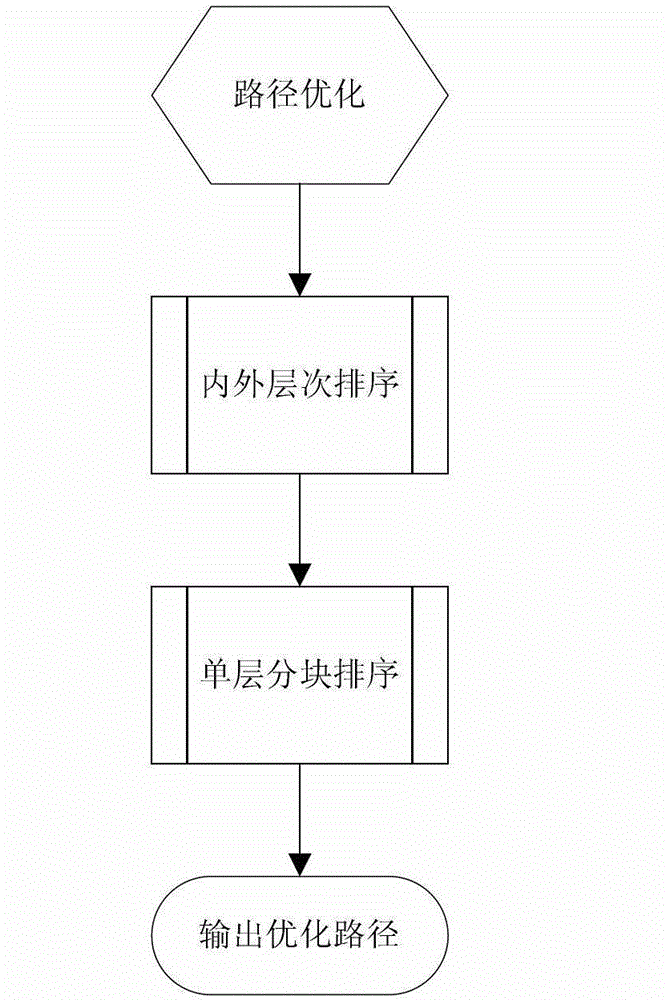

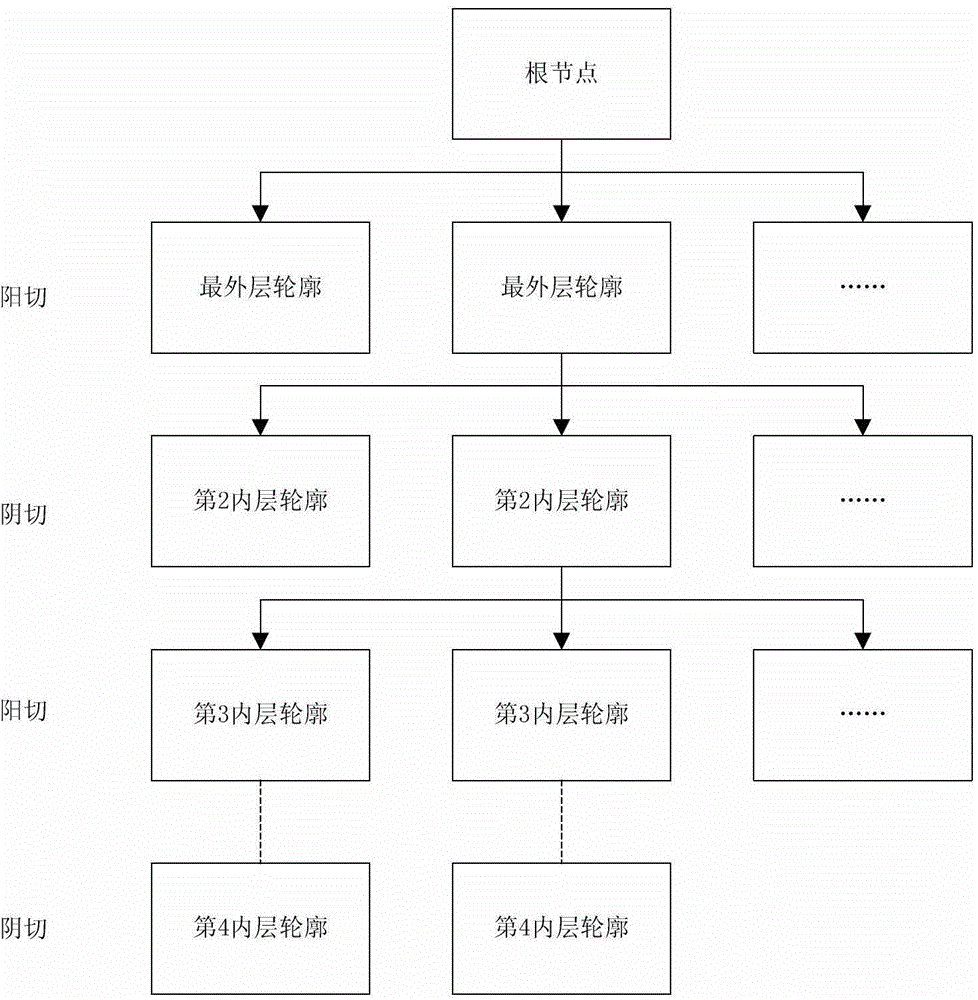

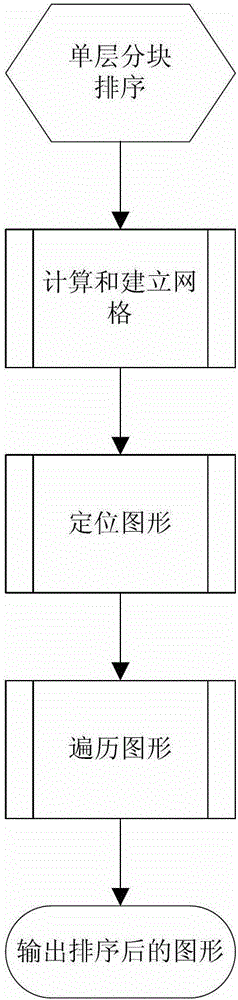

[0030] 1. Press first figure 1 The processing steps shown sort the inner and outer layers of each contour pattern: (a), take out all the contour patterns at the outermost layer in the graph, mount them under the root node of a tree, and set the fill type to Yang cut; (b) For each outline pattern of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com