Novel low-temperature infrared heated automatic deicing ground wire

An infrared and lightning protection wire technology, applied in the field of lightning protection wire, can solve the problems of limited scope of application, high current, inability to popularize and use, etc., and achieve the effect of easy processing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] 1. Overall

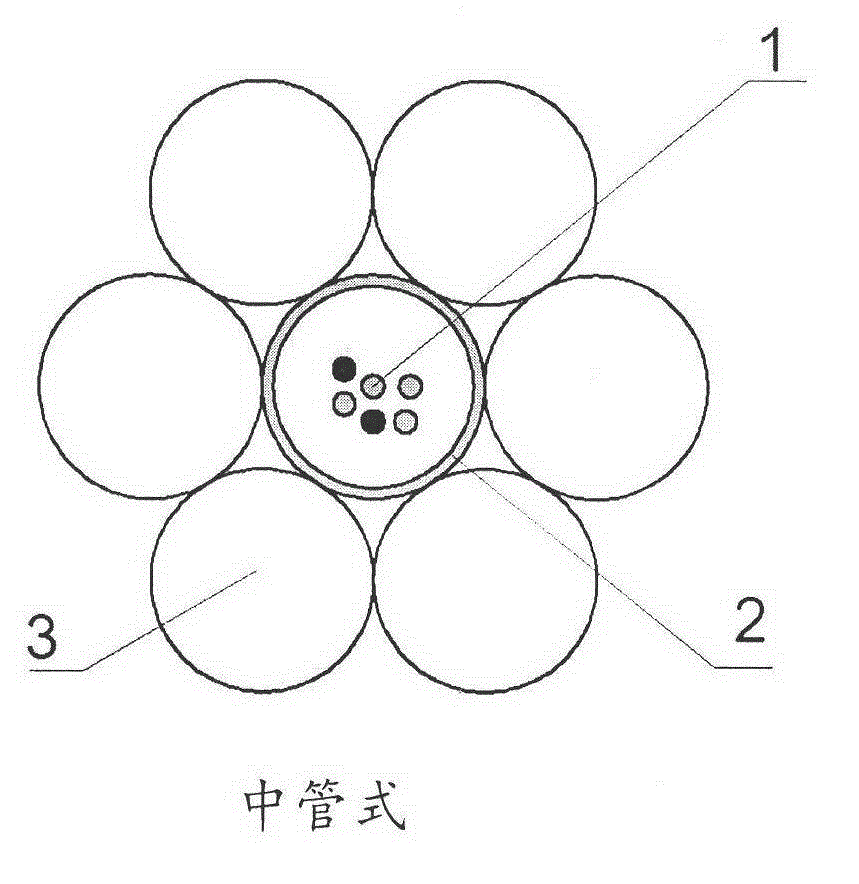

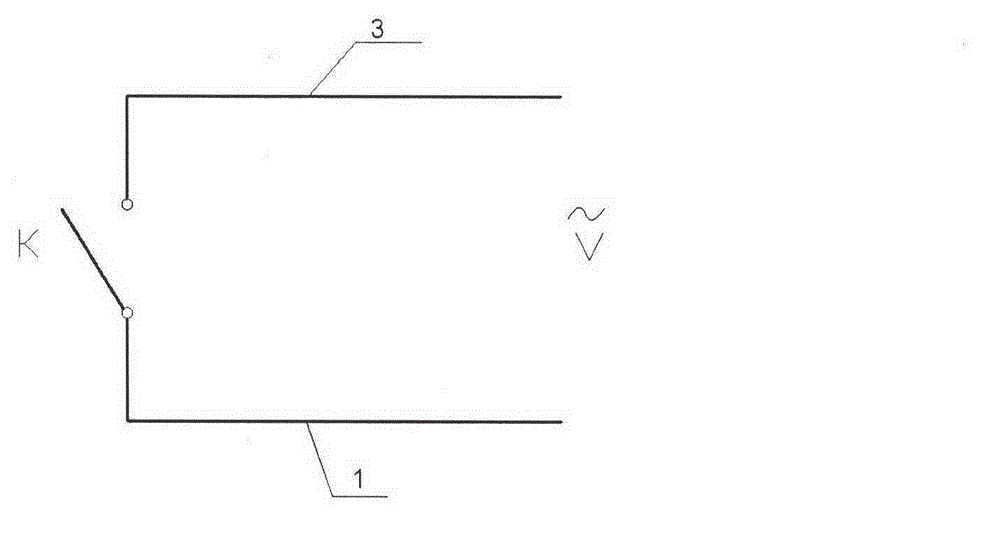

[0037] like figure 1 , the invention includes an auxiliary heating wire (1) made of conductive polyester fiber capable of generating low-temperature infrared heat energy, a high thermal conductivity insulating sheath (2), and a steel hinge wire (3).

[0038] The auxiliary heating wire (1) is made of a high thermal conductivity insulating material as a sheath (2), insulated from the steel hinge wire (3), and twisted around the center of the steel hinge wire (3) to become one.

[0039] 2. Functional parts

[0040] 1. Auxiliary heating wire (1) is made of conductive polyester fiber that can generate low-temperature infrared heat energy. According to the needs of different wire diameters and calorific value, multiple fibers can be twisted together, and then high thermal conductivity insulating material can be used as The sheath (2) generates infrared heat energy after electrification.

[0041] 2. The high thermal conductivity insulating sheath (2) is made of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com