Magnetic suspension type motor base

A motor seat and magnetic levitation technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of increasing the friction loss of motor bearings, reducing the service life of the motor, heating, etc., to reduce the service life, reduce noise and vibration, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the scope described in the embodiments.

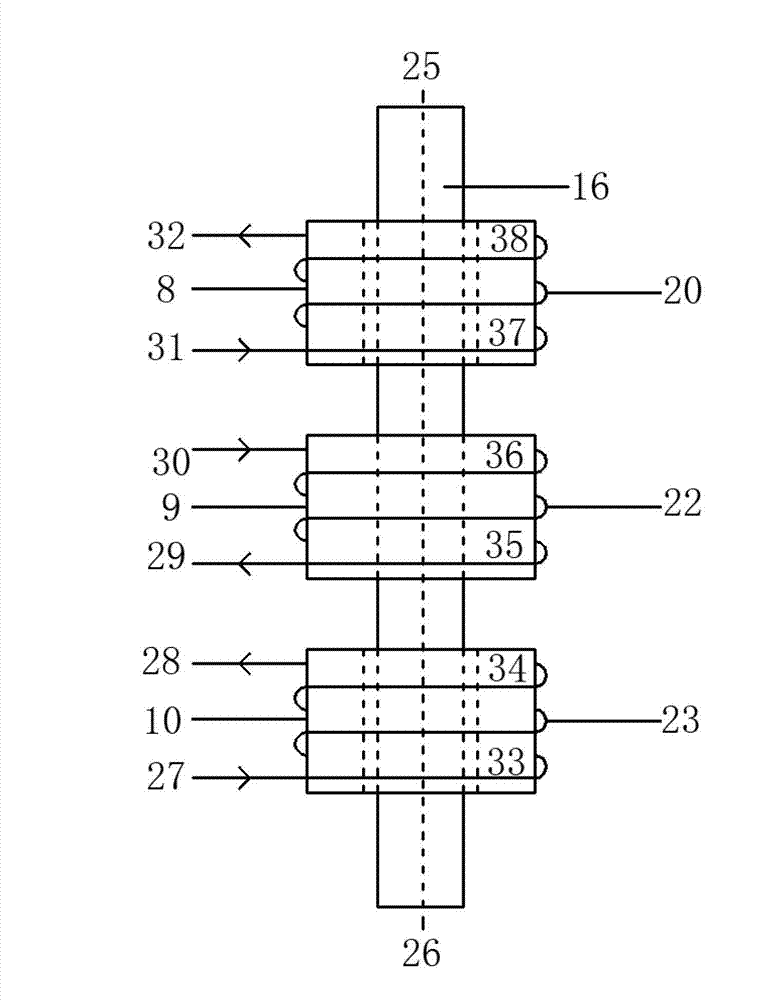

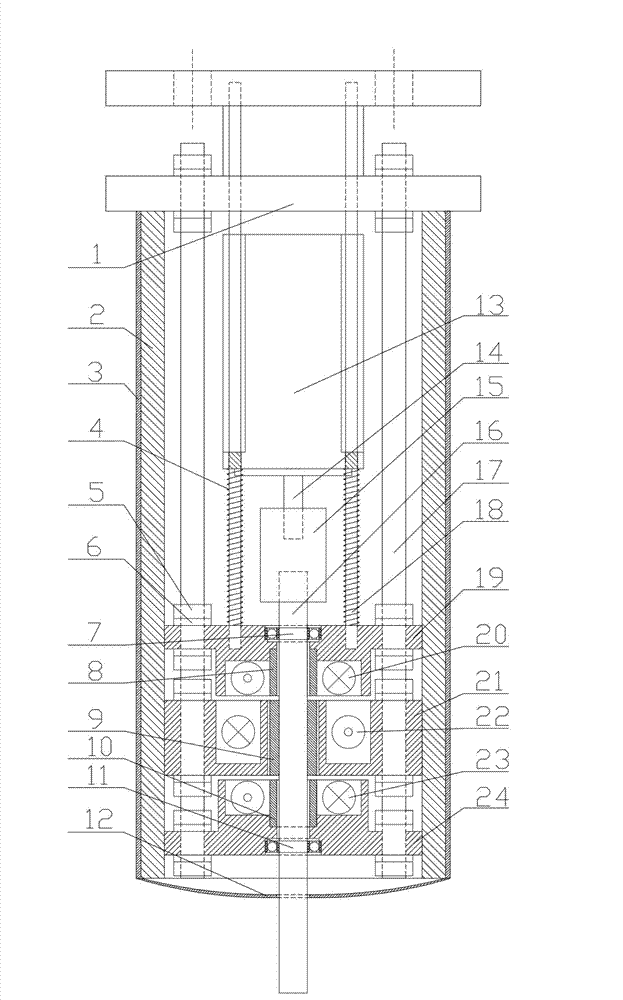

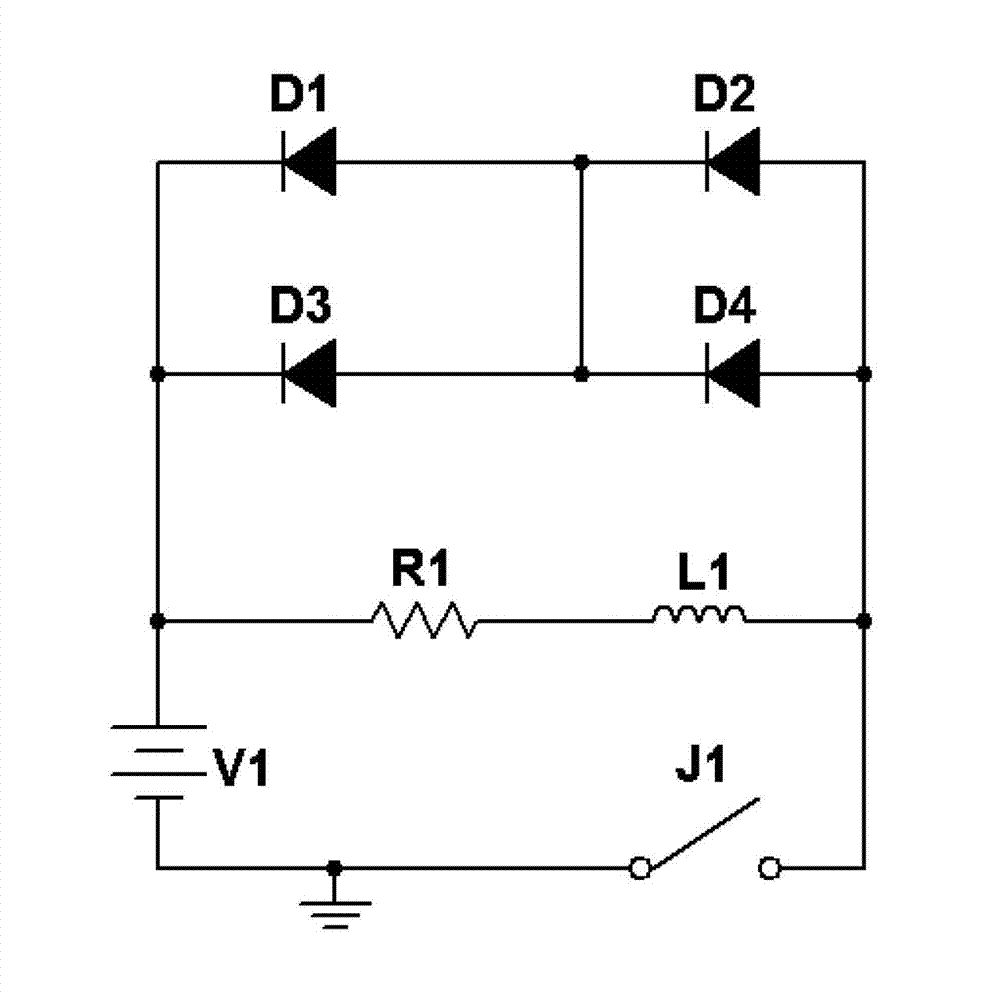

[0028] Such as Figure 1-3 As shown, a magnetic levitation motor seat mainly includes a transmission main shaft 16, an upper magnetic ring 8, a middle magnetic ring 9, a lower magnetic ring 10, an upper magnetic ring seat 19, a middle magnetic ring seat 21, a lower magnetic ring seat 24, a top seat 1. Prop 18, long screw shaft 17, upper auxiliary excitation coil 20, middle auxiliary excitation coil 22 and lower auxiliary excitation coil 23.

[0029] The drive shaft 16 is connected to the output shaft 14 of the motor 13 through a coupling 15; the upper magnetic ring 8, the middle magnetic ring 9, and the lower magnetic ring 10 are ring-shaped hollow magnets, and the upper magnetic ring 8 and the lower magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com