Hanging valve tower for converter valve

A converter valve and valve tower technology, which is used in output power conversion devices, electrical components, cooling/ventilation/heating renovation, etc. Design simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

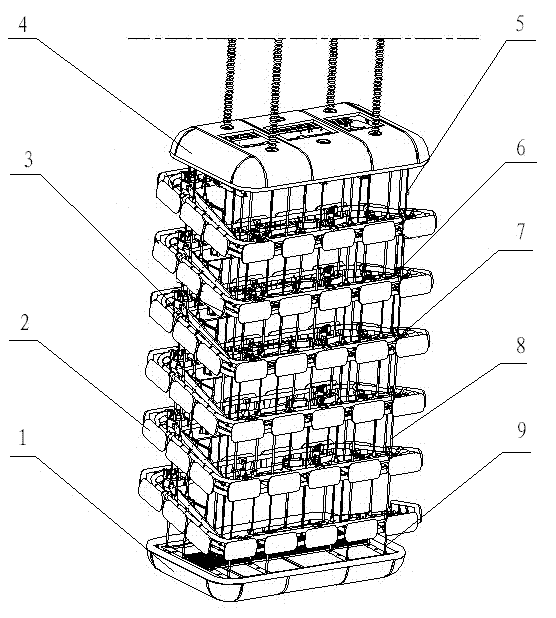

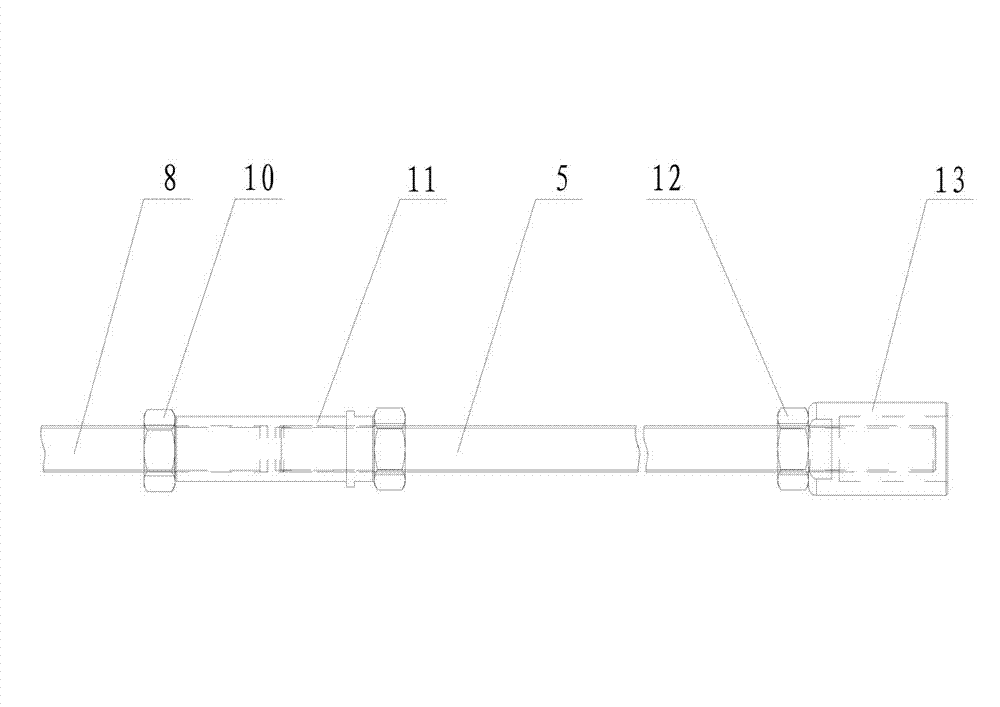

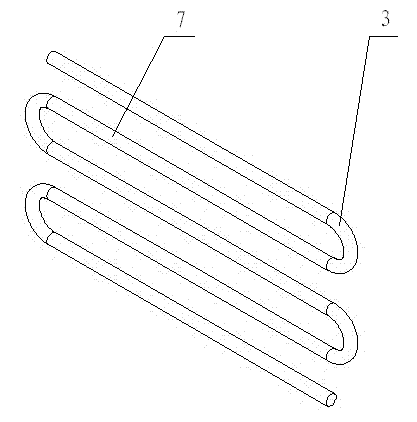

[0016] The embodiment of the suspension valve tower of the diverter valve of the present invention: as figure 1 As shown, it includes five valve layers 6 arranged at intervals up and down, wherein the uppermost valve layer is the top valve layer, and the lowermost valve layer is the bottom valve layer, and each valve layer 6 represents an independent electrical unit, adjacent The two valve layers 6 are connected by an interlayer connection structure, and an intermediate shield 2 is provided on the outside of each valve layer 6; a top shield 4 is arranged above the top valve layer, and the top shield 4 and the top valve layer pass through The top connection structure is connected, and the bottom shielding cover 1 is provided under the bottom valve layer, and the bottom shielding cover 1 and the bottom valve layer are connected through the bottom connection structure; in addition, the electrical unit module on the valve layer 6 is also provided on the valve tower A water cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com