Slag micro powder machining process

A technology of slag micro-powder and processing technology, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., to achieve the effects of reducing power consumption per unit production, significant economic efficiency, and small maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

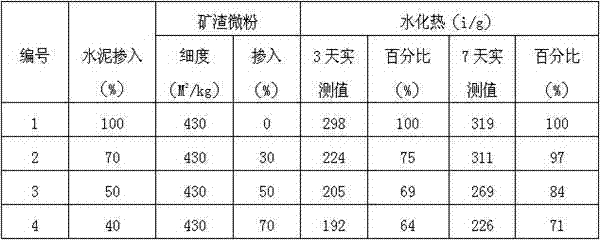

[0013] Slag fine powder is a powdery product obtained by superfine grinding the slag discharged from the ironmaking blast furnace with a small amount of grinding aid. Its main component is SiO 2 、Al 2 o 3 , CaO, etc., all have high activity. Incorporate it into cement concrete as an admixture, these active SiO 2 、Al 2 o 3 C 2 S and C 2 The hydration products produced by S hydration are filled in the voids of cement concrete, which greatly increases the density of cement concrete, and at the same time, the lower strength Ca(OH) 2 The crystals are converted into calcium silicate hydrate gel with higher strength, so that a series of properties of cement concrete are significantly improved.

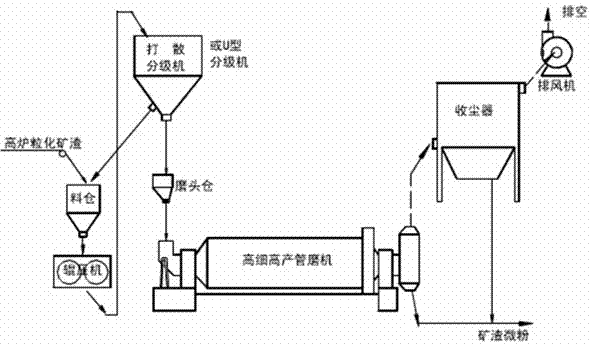

[0014] The invention provides a processing technology of slag micropowder. The processing flow is as follows: firstly, the slag is squeezed and pulverized by a roller press from a hopper, and then enters a dispersing classifier for sorting, and the fine material (particle size ≤ 2 mm)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com