Novel foaming formula of polypropylene plastic

A polypropylene plastic and formula technology, which is applied in the field of plastic foaming formula, can solve the problems of insufficient gas generation, inability to discharge all decomposed products, product pollution, and yellow surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take 90 kg of polypropylene plastic, 5 kg of AC, and 5 kg of N1000. Stir until uniform, then send the prepared material to the single-screw mixer for granulation, the granulation temperature is 170°C, and then put the prepared granules into the injection molding machine for injection molding. The injection molding processing temperature range of the new polypropylene plastic formula is 180°C.

Embodiment 2

[0019] Take 96 kg of polypropylene plastic, 2 kg of AC, and 2 kg of N1000. Stir until uniform, then send the prepared material to the single-screw extruder for granulation, the granulation temperature is 180°C, and then put the prepared granules into the injection molding machine for injection molding. The processing temperature range of PP injection molding is 190°C.

Embodiment 3

[0021] Take 99 kg of polypropylene plastic, 0.3 kg of AC, and 0.3 kg of N1000. Stir until uniform, then send the prepared material to a single-screw mixer for granulation, the granulation temperature is 200°C, and then put the prepared granules into the injection molding machine for injection molding. The processing temperature range of PP injection molding is 250°C.

[0022] When stirring, it should be prepared under (1) normal temperature and normal pressure, and (2) clean the mixing tank before stirring and discharging.

[0023] The granulation problem is not easy to be too high,

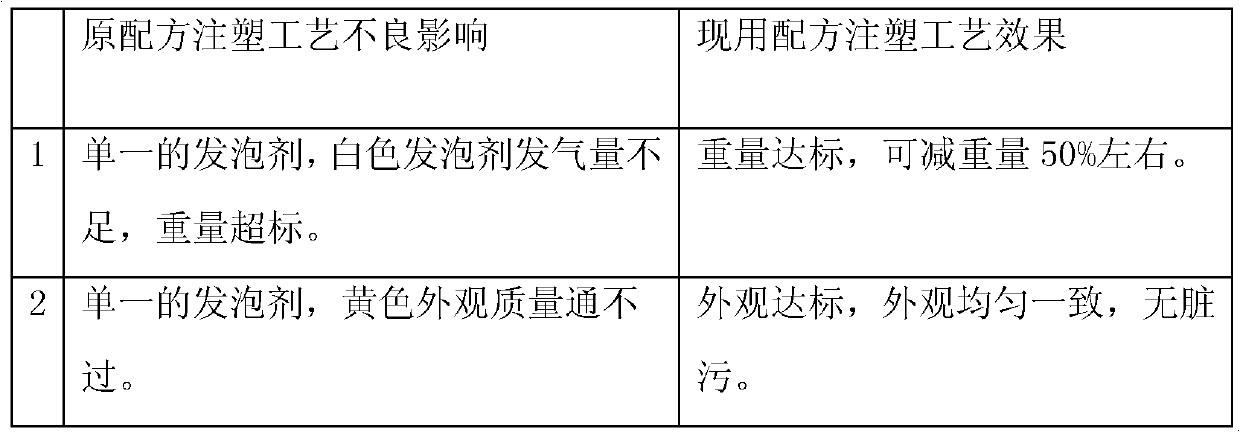

[0024] Comparison of injection molding process effect before and after foaming formula of polypropylene plastic:

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com